Product Details

|

Name |

Plastic-rubber overmold vacuum casting parts |

|

Product Size |

According to customized Size |

|

Product Color |

Refer to customer request |

|

Material |

PBT,PP, PC, Nylon, ABS, Rubber, silicone, TPU etc. |

|

Surface Treatment |

polishing, deburr, surface marking etc. |

|

Application |

Household appliances, industrial manufacturing, office equipment, auto parts, medical equipment, craft toys, robots, aerospace etc. |

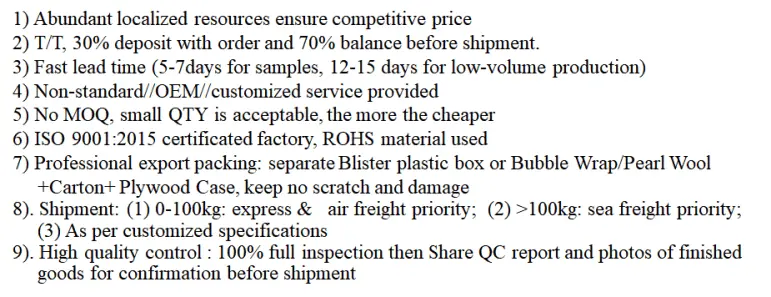

Delivery

Why Choose ShenZhenHuangCheng Technology?

● Experienced team of engineers and technicians with in-depth knowledge and years of hands-on expertise, capable of handling complex projects and providing innovative solutions tailored to your needs.

● State-of-the-art equipment for precise manufacturing, leveraging the latest technology to ensure every product meets strict dimensional and quality standards, delivering consistent, top-notch results.

● Comprehensive quality control measures are implemented at every production stage, from raw material inspection to final product testing, guaranteeing that only flawless items reach customers.

● Flexible production capabilities allow us to accommodate various order sizes, production schedules, and customization requests, ensuring a seamless manufacturing experience for clients.

● Competitive pricing without compromising quality, achieved through efficient production processes and strategic sourcing, enabling you to get high-quality products at cost-effective rates.

Introduction

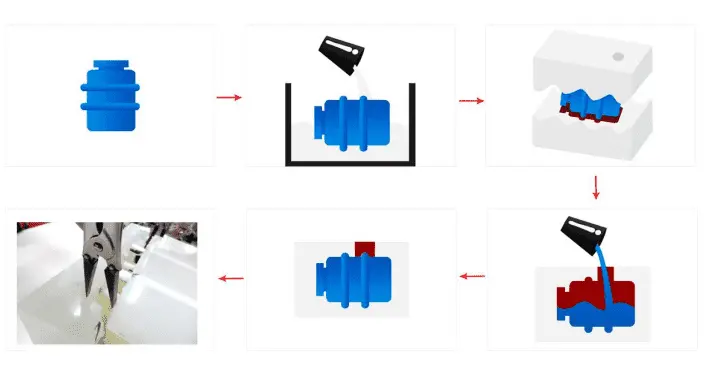

Plastic-rubber overmold vacuum casting parts are produced through a meticulously engineered and highly efficient process. It all starts with a benchmark sample or a precisely fabricated prototype, which is developed in strict compliance with the client's comprehensive and detailed drawings. Using advanced techniques, we then create a highly accurate silicone mold that flawlessly captures every minute and intricate detail of the original design, ensuring a perfect replication base. Subsequently, the plastic components are expertly machined. Depending on the specific requirements of the project, we utilize either the highly precise CNC machining method, which is ideal for achieving tight tolerances and smooth finishes, or the versatile 3D printing technology, allowing for the creation of complex geometries with ease. Once the plastic parts are ready, the process moves to the final crucial stage. Under a carefully controlled vacuum state, the rubber-like material is skillfully poured into the silicone mold. This vacuum environment plays a vital role, as it effectively eliminates any air bubbles, resulting in a seamless, professional-grade finish. The outcome is an exact replica of the original sample or prototype, maintaining the highest standards of quality and precision. Moreover, understanding the diverse aesthetic needs of our clients, various pigments can be seamlessly incorporated into the casting material. This flexibility enables a wide spectrum of color customization, ensuring that the final product not only meets functional requirements but also stands out with its visual appeal.

Outstanding features

1. Fast performance: When the silicone mold has a prototype, it can be made within 24 hours, and the product can be poured and replicated.

2. Simulation performance: Silicone molds can make silicone molds with complex structures and fine patterns, which can clearly outline fine lines on the surface of product and reproduce the fine features on prototype parts well.

3. Release performance: Because silicone mold has good flexibility and elasticity, for parts with complex structure and deep grooves, the parts can be taken out directly after pouring without increasing the draft angle and simplifying the mold design as much as possible.

4. Replication performance: silicone rubber has excellent simulation and extremely low shrinkage (about 3 ‰), basically without losing dimensional accuracy of the parts. It is an excellent mold material. It can quickly make 20-30 pieces of the same product by using a silicone mold.

5. Scope of selection: Silicone composite molding materials can be widely selected, which can be ABS-like, polyurethane resin, PP-like, nylon-like, rubber-like, PA-like, PE-like,PC-like transparent parts, soft rubber parts , high temperature parts, fireproof and other materials.

Plastic-rubber overmold vacuum casting parts for review

Shipping

FAQs

Q: What's the minimum order quantity for products?

A: We can accommodate orders as low as 10 pieces, making us ideal for prototyping and small production runs.

Q: How long does it take to produce products?

A: Typical lead times range from 5-15 days, depending on the complexity and quantity of the parts.

Q: Can you help with material selection for my specific application?

A: Absolutely! Our team of experts can guide you in choosing the best plastic and rubber combinations for your needs.

Q: Are your products suitable for outdoor use?

A: Yes, we can produce parts with UV-resistant and weatherproof properties for outdoor applications.

Q: How do you ensure the quality of your plastic-rubber overmold vacuum casting parts?

A: We employ strict quality control measures throughout the production process, including 3D scanning and dimensional checks.

YOU MAY LIKE

_1744788508965.png)