Product Details

|

Product |

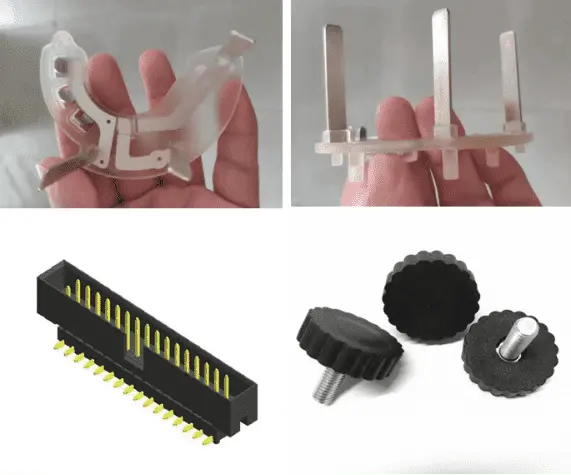

Metal-plastic overmold vacuum casting parts |

|

Size |

Customized Size |

|

Color |

Customized Color |

|

MOQ |

1 piece |

|

Material |

Metal, aluminum alloy, copper, brass, stainless, steel; ABS-like,PP-like,PC-like,Nylon-like etc. |

|

Finishing |

Electroplating, coating , painting,polishing , silk-screen etc. |

Introduction

The vacuum casting principle for metal-plastic overmold parts is a sophisticated and precise manufacturing process. It initiates with the creation of a benchmark sample or prototype, meticulously crafted in strict accordance with the customer's detailed drawings. This initial model serves as the cornerstone for generating a highly accurate silicone mold, which is designed to capture every intricate detail, ensuring an exact replication of the original design. Subsequently, the metal components of the product are expertly fabricated. Depending on the complexity and specific requirements of the design, either 3D printing or CNC machining is employed. 3D printing offers the flexibility to produce complex geometries with ease, while CNC machining guarantees high precision and tight tolerances, ensuring the metal parts meet the most stringent quality standards. In the final stage, under a carefully controlled vacuum environment, the plastic-like material is poured into the silicone mold. The vacuum state is crucial as it effectively eliminates air bubbles, resulting in a flawless, seamless finish. This process successfully reproduces an identical replica of the original benchmark sample or prototype. To accommodate diverse color preferences, pigments can be added directly to the casting material during the pouring process. Alternatively, post-processing techniques such as dyeing or painting can be applied to the final product, providing endless possibilities for customization and ensuring the end result meets both functional and aesthetic requirements.

Industry application

The silicone vacuum casting process has emerged as a transformative manufacturing technique, finding extensive application across a wide spectrum of industries, including aerospace, automotive, home appliances, toys, and medical equipment. Its unique combination of cost - effectiveness, precision, and flexibility makes it an unparalleled choice for small - batch sample trial runs, typically ranging from 20 to 30 pieces, during the critical new product development phase. In the automotive sector, where innovation and rapid prototyping are key, this process plays an indispensable role in the research and development of auto parts. It empowers manufacturers to produce small batches of plastic components with exceptional accuracy, which are then utilized for comprehensive performance testing, seamless vehicle integration, and rigorous road trials. Common automotive plastic parts such as intricately designed air conditioner casings, robust bumpers, aerodynamic air ducts, vibration - dampening rubber - coated dampers, efficient intake manifolds, ergonomic center consoles, and detailed instrument panels can all be swiftly fabricated in small quantities using this process during the trial production stage. By enabling rapid iteration and refinement of designs, the silicone vacuum casting process significantly facilitates efficient product development and optimization, ultimately accelerating time - to - market and enhancing overall product competitiveness.

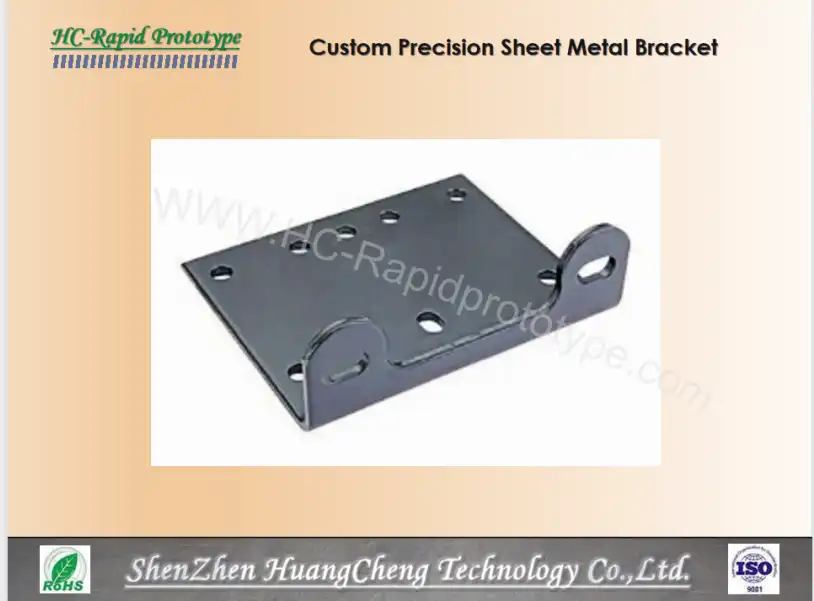

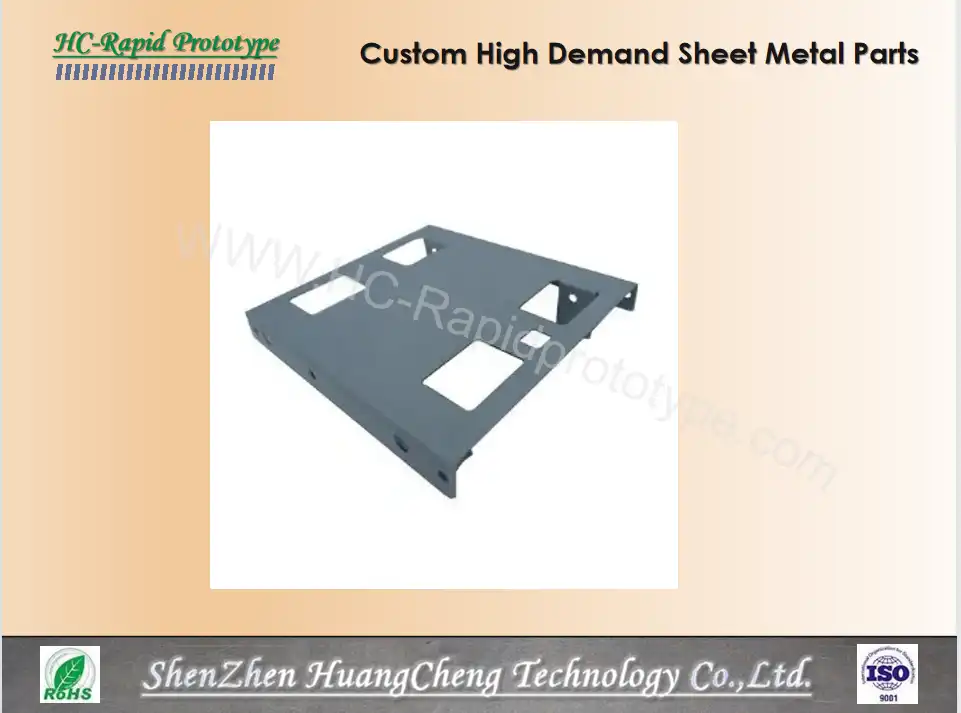

Metal-plastic overmold vacuum casting parts for reference

Production Process

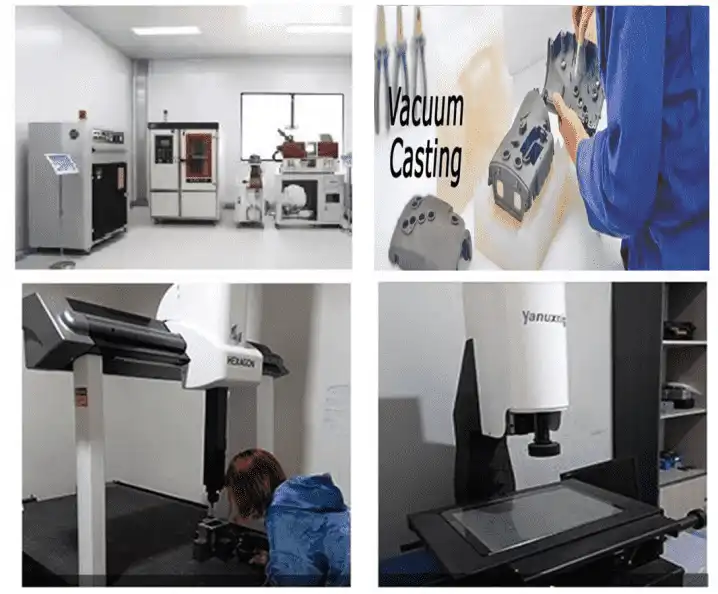

- 3D modeling and design optimization involves using advanced software to create detailed digital models. Engineers analyze and refine designs, ensuring functionality, aesthetics, and manufacturability before physical production.

- Mold creation using silicone rubber starts with a master model. Liquid silicone is poured around it, forming a flexible mold that accurately captures every detail, providing a reliable base for casting components.

- Metal-plastic overmold vacuum casting parts utilizes the silicone mold. Plastic resin is poured into the mold under vacuum, eliminating air bubbles and ensuring a smooth, high - quality finish for precise and consistent parts.

- CNC machining of metal inserts uses computer - controlled tools to precisely shape metal materials. This process achieves tight tolerances, creating strong, durable inserts that fit perfectly with plastic parts.

- The overmolding process to combine metal and plastic parts places pre - machined metal inserts into the mold, then injects plastic around them, fusing the two materials for enhanced strength and functionality.

- Quality inspection and testing involve rigorous checks at multiple production stages. Using various techniques, inspectors verify dimensions, material properties, and overall performance to ensure products meet high - quality standards.

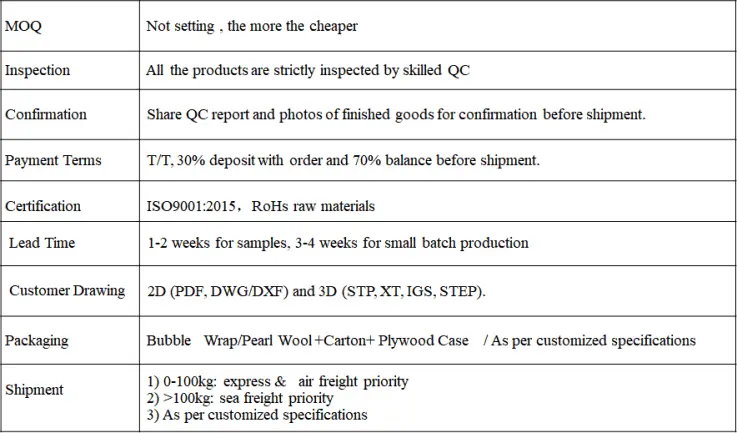

Delivery Terms

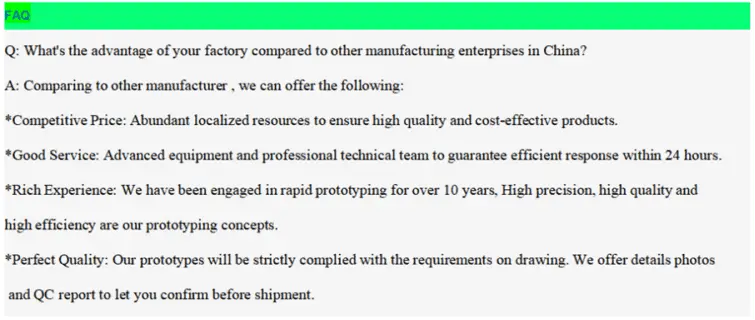

FAQ

YOU MAY LIKE

_1744788508965.png)