Features

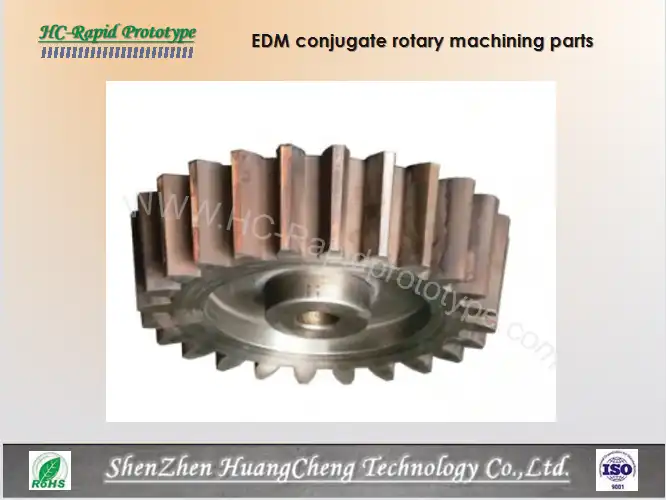

EDM conjugate rotary machining part stands out for its ability to operate with extremely small clearances, a feature that significantly reduces deviations in envelope shaping. By leveraging conjugate rotation and auxiliary motion, this advanced machining technique can handle a diverse range of complex surfaces, enabling the creation of intricate and precise components. It is particularly well - suited for processing cemented carbide and hardened steel parts, materials that are often challenging to machine using conventional methods. The machining accuracy of EDM conjugate rotary machining can reach the micron level, ensuring high - precision results. Additionally, it can achieve a surface roughness in the range of Rα0.32 - 0.04 microns, producing surfaces with an exceptional finish that meet the strictest quality standards.

Introduction

EDM conjugate rotary machining part is a highly sophisticated and versatile manufacturing technique that makes use of conjugate rotation and auxiliary motion. This combination allows it to perform a wide array of machining tasks with remarkable precision. It is capable of processing not only basic geometries such as cylindrical surfaces, conical surfaces, and planes but also more complex surfaces of revolution. Moreover, it can handle intricate shapes like involute, cycloid, and helical surfaces, as well as other complex geometries that pose challenges to traditional machining methods. One of the key advantages of EDM conjugate rotary machining is its suitability for working with tough materials. It is especially well - adapted for the machining of carbide and hardened steel, which are known for their hardness and abrasiveness. These materials are commonly used in industries where high - performance components are required, and traditional machining processes often struggle to produce accurate results. The machining accuracy of EDM conjugate rotary machining can reach the micron level. This high level of precision ensures that the final products meet the strictest dimensional and quality requirements. Whether it is for manufacturing precision parts for the aerospace, automotive, or mold - making industries, this technique provides reliable and consistent results, making it an invaluable asset in modern manufacturing.

Application

EDM conjugate rotary machining is often used for machining thread gauges, thread dies, carbide complex forming tools, Rolling dies, small diameter ball screws and nuts, carbide gears etc.

EDM conditions

To successfully implement Electrical Discharge Machining (EDM), three essential conditions must be met. First, a pulse power supply is indispensable. It delivers electrical energy in discrete pulses, enabling controlled and precise spark discharges that erode the workpiece material. Second, an automatic feed adjustment device is crucial. This device constantly monitors and maintains a minimal discharge gap between the tool electrode and the workpiece electrode, ensuring a stable machining process and preventing short circuits or excessive wear. Finally, the spark discharge must occur within a liquid medium with a specific dielectric strength ranging from 10 to 10⁷Ω m. This dielectric fluid serves to cool the electrodes, remove debris, and control the discharge process, facilitating accurate and efficient material removal.

Product Characteristics

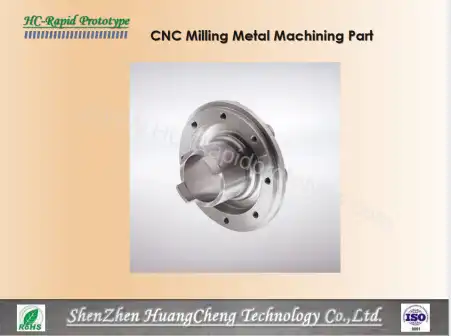

Our EDM conjugate rotary machining parts offer:

- Exceptional precision and accuracy are achieved through advanced measurement tools and cutting - edge machining technologies, ensuring components meet the strictest dimensional requirements for optimal functionality.

- Complex geometries and intricate details can be effortlessly crafted using multi - axis machining and innovative techniques, enabling the production of parts with unique and elaborate designs.

- An excellent surface finish is guaranteed by a combination of precise machining strategies and meticulous post - processing, resulting in smooth, flawless surfaces that enhance both appearance and performance.

- Consistent quality across large production runs is maintained via rigorous quality control measures at every stage, ensuring each unit meets the same high - standard specifications without variation.

- High durability and longevity are inherent, thanks to the use of premium materials and specialized manufacturing processes that enhance resistance to wear, fatigue, and environmental factors.

Delivery terms

FAQs

Q1: Do you accept OEM and ODM business?

A1: We accept OEM and ODM with your authorization.

Q2: Can you provide one-stop service including of material, processing, finish, assembly etc.?

A2: Yes, we can.

YOU MAY LIKE

_1744788508965.png)