Product Details

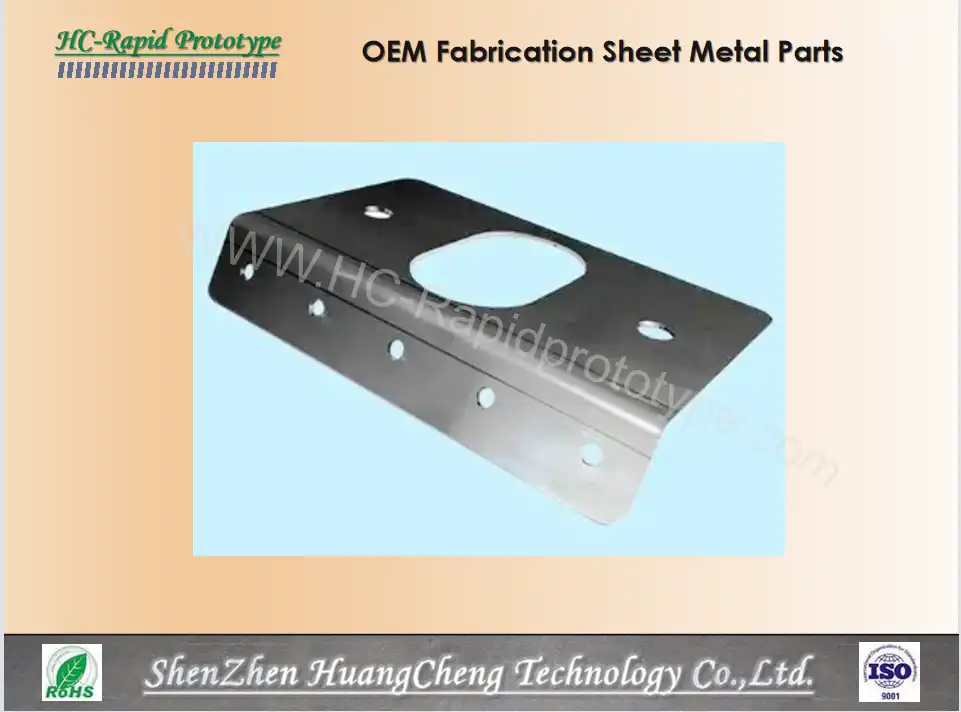

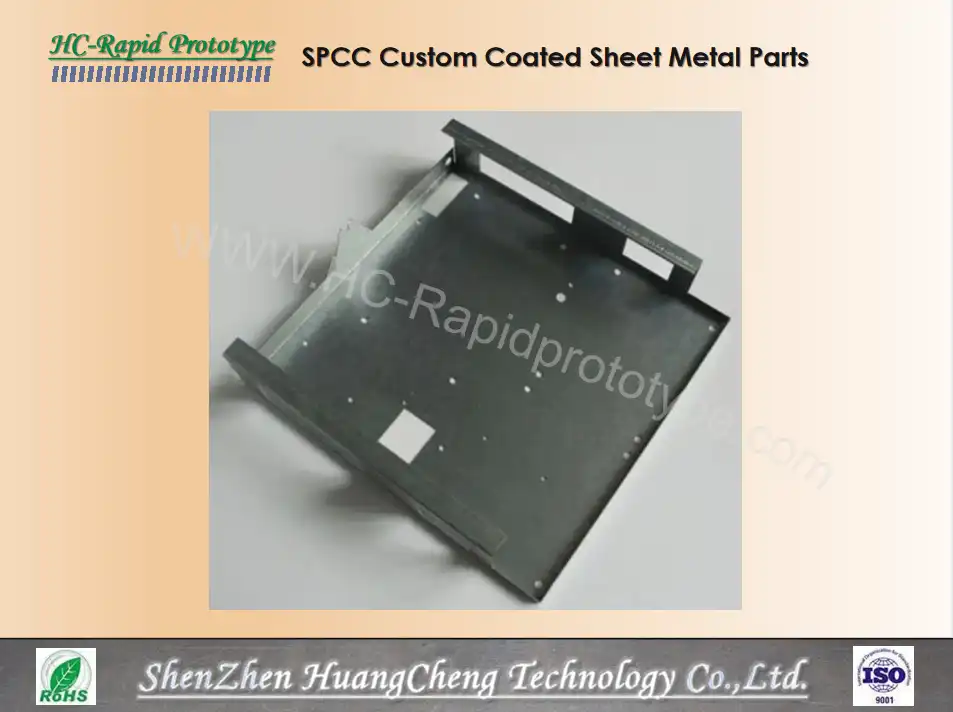

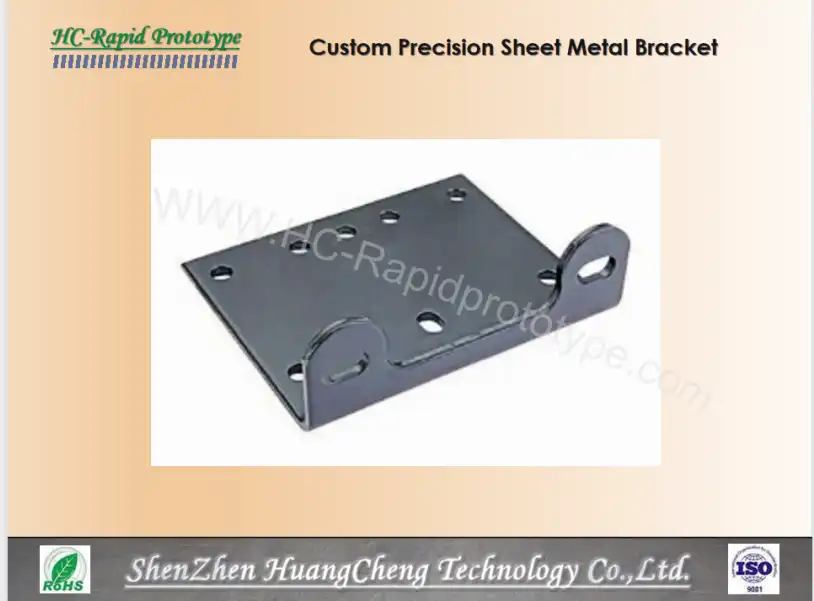

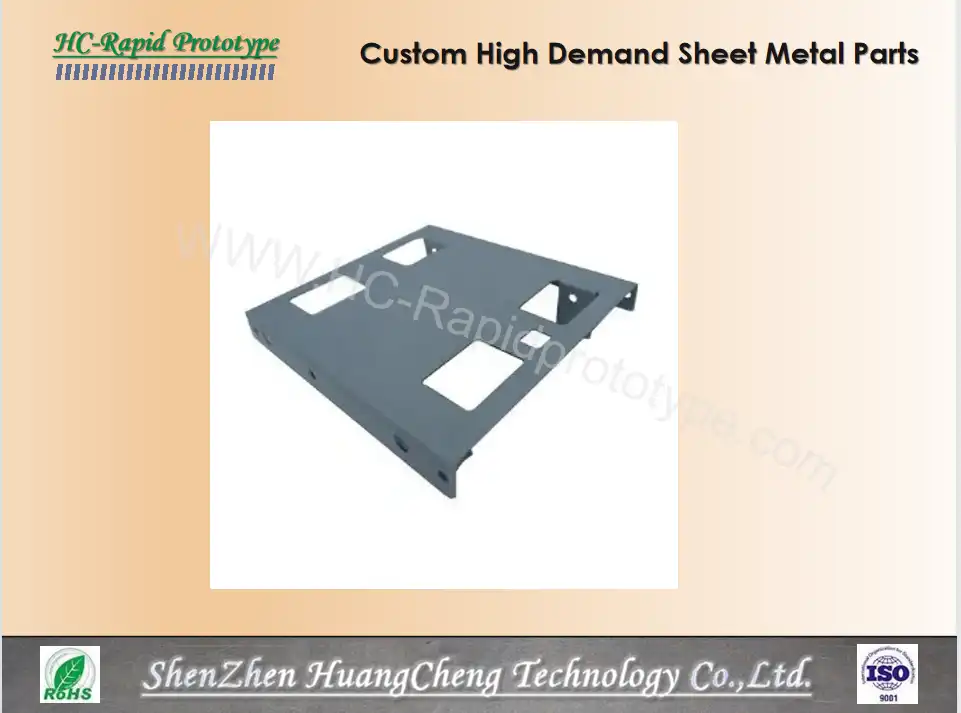

Product Name: OEM Fabrication Sheet Metal Parts

Product Size: OEM definition

Product Color: Depending on surface treatment

MOQ: 1 piece, the more the cheaper

Lead Time:1-2 weeks for samples, 3-4 weeks for small batch production

Payment Terms: T/T, 30% deposit with order and 70% balance before shipment.

Raw Material: Aluminum, Stainless Steel, Brass ,Copper, Metals etc.

Finishing: Polishing, Zinc plating, Powder coating, Chrome plating, Nickel plating, etc.

OEM Drawing: 2D (PDF, DWG, DXF) / 3D ( IGS, STP, STEP, XT)

Introduction

OEM Fabrication Sheet Metal Parts come into being through elaborate manipulation of diverse sheet metal methodologies. These parts have firmly embedded themselves in all facets of our daily existence. Whether it's the household appliances we rely on, the vehicles navigating our streets, or the electronics we use daily, sheet metal components are essential. In the automotive domain, they construct the body frameworks, safeguarding passengers and maintaining structural soundness while also optimizing aerodynamics. In aerospace, they are utilized to fashion lightweight yet sturdy aircraft elements, facilitating efficient flight and conserving fuel. The production of these parts involves an extensive range of techniques. Filament power winding imparts strength and resilience; laser cutting excels in delivering high - precision, complex shapes; heavy - duty machining creates robust components; metal bonding offers a secure means of joining parts; metal drawing shapes the metal as required; plasma cutting efficiently removes material; precision welding ensures reliable connections; roll forming enables the continuous production of uniform profiles; sheet metal bending fabricates angled structures; die forging produces high - strength parts; and water jet cutting provides clean, accurate cuts. Each approach has its own merits, and the selection depends on aspects such as part intricacy, precision requirements, and production scale. Sheet metal processing is a holistic cold - working procedure applied to thin metal sheets, usually with a thickness of 6mm or less. It involves numerous operations, including shearing for separating metal, punching, cutting or compounding to create openings and forms, folding to generate angles, welding for assembly, riveting for mechanical fixation, splicing for part combination, and various forming processes similar to those in automotive body manufacturing. This flexibility allows for the fabrication of parts with a vast array of shapes and functions. A key characteristic of sheet metal parts is the consistent thickness across the entire component. This uniformity guarantees stable performance in different applications. It simplifies the design and manufacturing workflows and aids in predicting how the parts will respond to various loads and environmental factors. Moreover, progress in sheet metal processing technologies, like computer - aided design (CAD) and computer - aided manufacturing (CAM), has significantly boosted production accuracy and efficiency. These tools allow designers to develop detailed 3D models, simulate part performance, and generate precise production guidelines, thereby reducing mistakes and minimizing material waste. Consequently, sheet metal parts keep evolving, satisfying the increasing needs of contemporary industries and enhancing the quality of products we use every day.

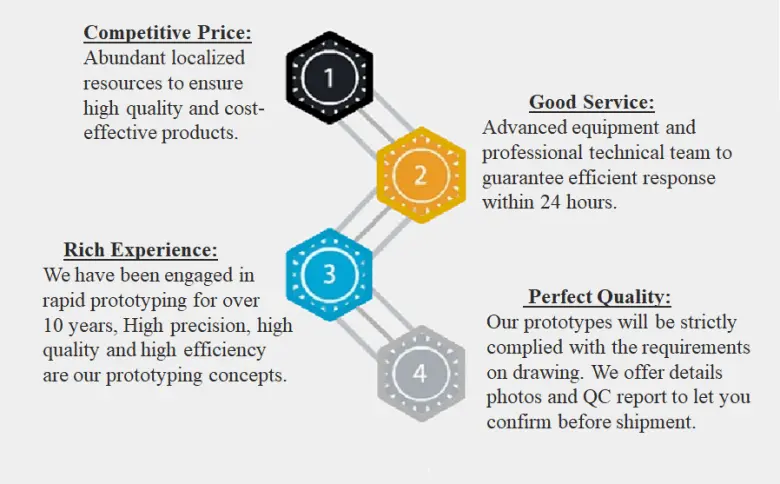

Our Service and Advantages

Comparing to other manufacturer , we can offer the following:

Deliver, shipping and serving

- Packing:

- Method 1: We first wrap the products with shrink film to protect them from dust and moisture, then load them in bulk for efficient transportation.

- Method 2: For better protection, we can pack the items into cartons or wooden cases, providing sturdy containment during transit.

- Method 3: Understanding diverse needs, we're ready to follow any specific packing requests from customers to meet their unique requirements.

- Shipping:

- We offer comprehensive shipping options including Express for urgent deliveries, Sea freight for large - volume and cost - effective transport, Land freight for regional transit, and Air freight for fast global shipping.

- Fabrication processes:

- Once we receive your order, we calculate the material quantity needed, check stock availability, prepare fabrication drawings, cut the material, perform stamping, remove burrs, conduct surface treatment, inspect quality, and finally pack the products.

FAQ

YOU MAY LIKE

_1744788508965.png)