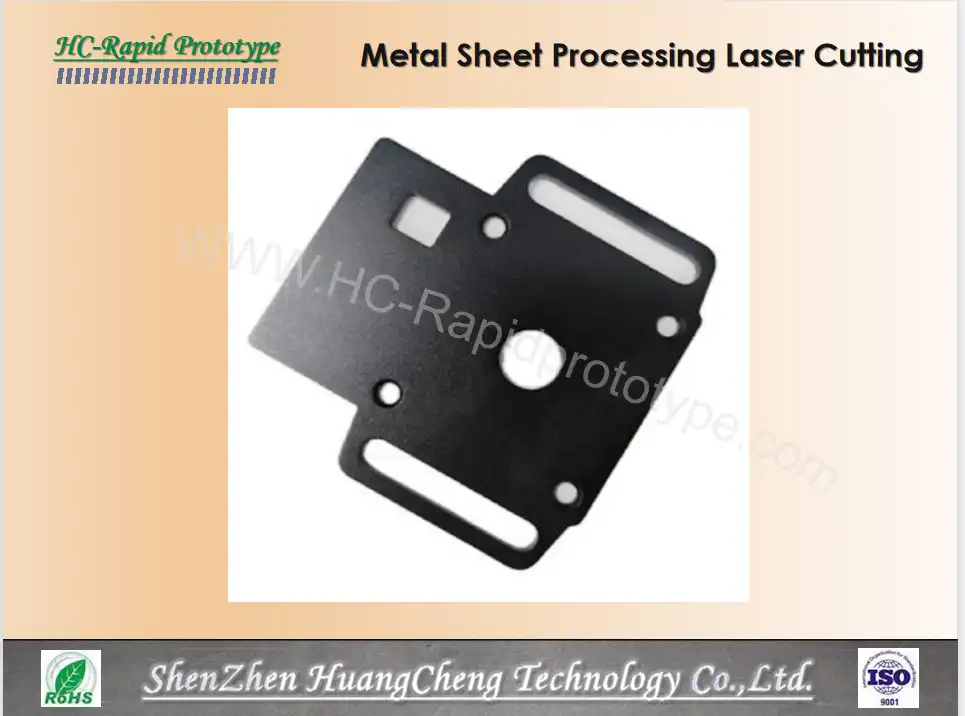

Product Details

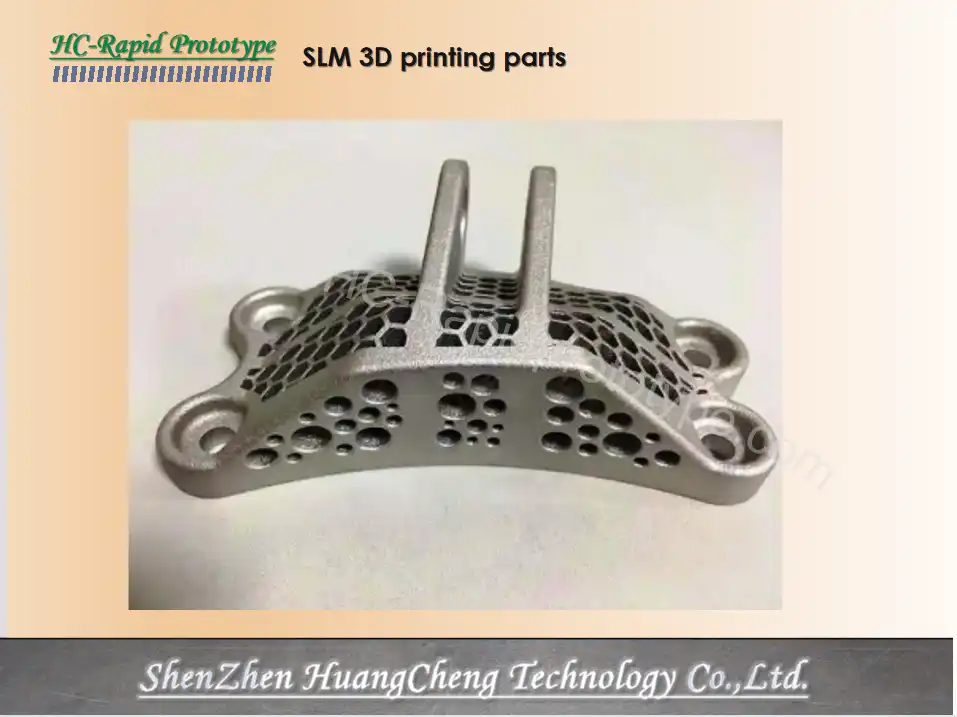

Name: SLM 3D printing parts

Size: Customized Size

Processing: Metal 3D printing

Material: Steel, stainless steel, aluminum alloy, copper, copper-tin alloy, titanium alloy etc.

Surface finish: Sandblasting, polishing, painting etc.

Application: Industrial parts, auto parts, aerospace and medical etc.

Introduction

The basic principle of laser selective melting technology (SLM) involves a multi - step process. Initially, three - dimensional modeling software such as Pro/e, UG, and CATIA are employed to meticulously design the three - dimensional solid model of the part on a computer. This digital model serves as the blueprint for the subsequent stages. Next, the slicing software comes into play, dissecting the three - dimensional model into numerous thin layers, thereby generating contour data for each section. Based on this contour data, a filling scanning path is created. The SLM 3D printing parts then precisely follows these scanning lines, controlling the laser beam to selectively melt the metal powder material layer by layer. As each layer solidifies, it adheres to the previous one, gradually stacking up to form a complete three - dimensional metal part. SLM is particularly advantageous for manufacturing complex metal components that are either extremely challenging or prohibitively expensive to produce using traditional manufacturing processes. Additionally, it offers excellent potential for weight reduction applications and is an ideal choice for creating dense parts with high precision and intricate geometries.

Advantages

- Various metals are available. "Pure" metal materials can be printed, as well as alloy materials. Our cutting - edge technology encompasses an extensive range of metallic substances. High - purity metals such as titanium, prized for its strength - to - weight ratio and biocompatibility; aluminum, valued for its lightweight and corrosion - resistant properties; and stainless steel, renowned for its durability and hygiene, are all viable options. Moreover, we offer custom - formulated alloy blends that combine the benefits of multiple elements, delivering enhanced performance in terms of strength, corrosion resistance, or heat tolerance. Whether clients seek the specific characteristics of pure metals or the optimized functionality of alloys, our precise printing process can meet their diverse material needs with accuracy and consistency.

- Ability to achieve complex shapes or internal features (difficult or expensive to achieve through traditional manufacturing). By harnessing state - of - the - art additive manufacturing techniques, we have the capacity to fabricate parts with highly intricate geometries and elaborate internal structures that are either extremely challenging or cost - prohibitive to produce using conventional manufacturing methods. This includes the creation of lattice structures for significant lightweighting, complex internal channels for efficient fluid flow management, and organic - inspired shapes that maximize product functionality. These innovative designs not only break the barriers of traditional manufacturing but also open up new avenues for product innovation across various industries, enabling the development of more efficient, effective, and groundbreaking products.

- Shorten lead time as no tools are required. In contrast to traditional manufacturing approaches, which typically involve time - consuming tooling processes like mold creation, die - casting, or fixture setup that can extend project timelines significantly, our manufacturing method completely eliminates these steps. By directly transforming digital designs into physical parts through additive manufacturing, we can circumvent the long - lead processes associated with tool production. This streamlined approach allows for rapid prototyping, quick iterations, and swift turnaround of production orders. As a result, clients can accelerate their product development cycles, bring new products to market more rapidly, and respond with agility to evolving market demands and customer needs.

- Parts merging, allowing multiple parts to be produced at the same time. Our advanced manufacturing process enables the seamless integration of multiple components into a single, cohesive structure, which not only streamlines the assembly process but also significantly reduces the overall part count. This parts - merging capability simplifies production logistics, minimizes potential points of failure by eliminating the need for additional fasteners or joints, and enhances the structural integrity of the final product. Furthermore, the simultaneous production of multiple parts optimizes resource utilization, maximizes production efficiency, and reduces both the manufacturing time and associated costs, providing clients with a more cost - effective and time - saving solution for their production requirements.

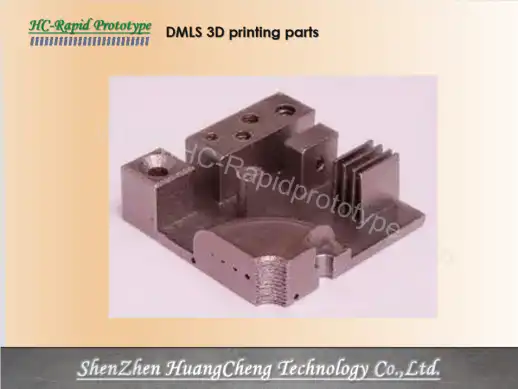

*Some SLM 3D printing parts for reference

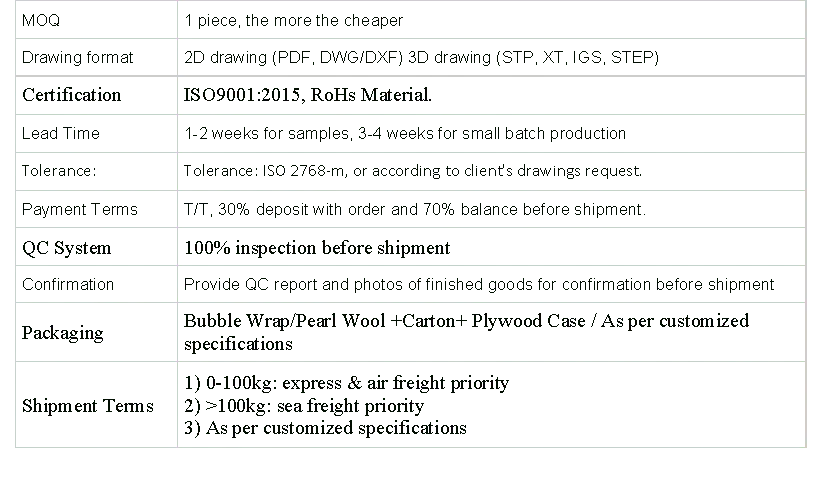

Delivery terms

FAQ

YOU MAY LIKE

_1744788508965.png)