Silica Properties

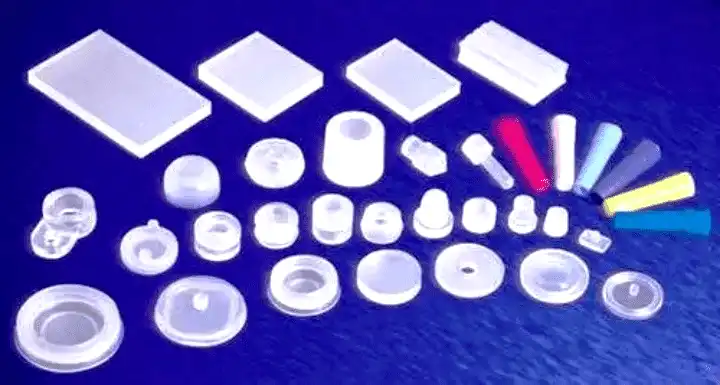

Silicone vacuum casting part, a highly active adsorption material, is an amorphous substance with the chemical formula mSiO2·nH2O. It exhibits remarkable chemical inertness, reacting only with strong alkalis and hydrofluoric acid. Insoluble in water and any solvent, it is non-toxic, odorless, and maintains excellent chemical stability, making it suitable for a wide range of applications. Its unique properties stem from the diverse microporous structures formed by different manufacturing methods. These structures, combined with its specific chemical composition and physical characteristics, endow silica gel with qualities that are difficult to match. It boasts high adsorption capabilities, enabling it to effectively capture and retain various substances. Its outstanding thermal stability allows it to withstand high temperatures without degrading, while its stable chemical properties ensure consistent performance across different environments. With high mechanical strength, it can endure physical stress without damage. Silica gel is classified into several types, such as macroporous silica gel, coarse-pored silica gel, B-type silica gel, and fine-pored silica gel, based on the size of its pores, each with distinct features catering to specific industrial and consumer needs.

Introduction

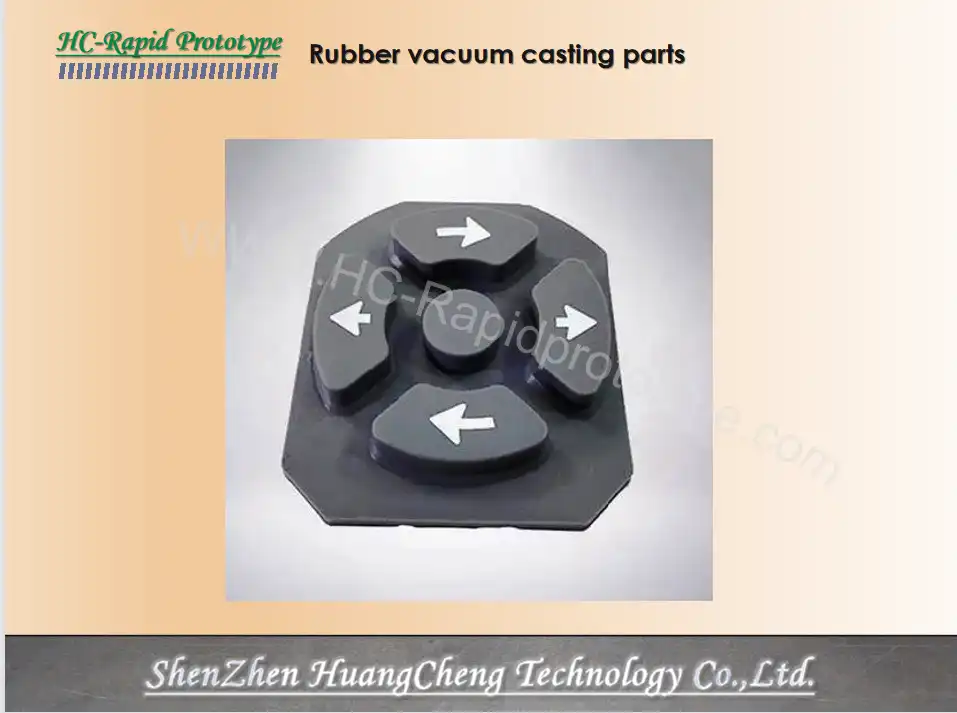

Prototyping silicone is a specialized type of silicone product predominantly utilized for the fabrication of prototypes. The Silicone vacuum casting parts designed for prototyping exists as a flowing liquid, encompassing various formulations. For instance, Translucent silicone 905, with a Shore hardness of 35 - 40 degrees, translucent silicone 918, and fully transparent silicone T - 4, which has a hardness of 38 - 42 degrees, are among the commonly used varieties. Notably, regardless of its color, the quality remains consistent, ensuring reliable and uniform results. This characteristic makes it an ideal choice for creating a wide array of silicone models, especially suitable for products with less complex geometries. On the other hand, hand model silicone is a specific kind of silicone rubber primarily intended for the production of hand models. In its natural state, it is liquid, allowing for easy manipulation, and its color can be customized according to specific requirements. When in use, by adding a curing agent in the correct proportion, it can cure and solidify within a few hours, transforming into a durable form. Beyond its application in prototyping, hand model silicone also offers the advantage of enabling small - batch replication of products, providing flexibility and efficiency in manufacturing processes.

Application

Silicone vacuum casting part has emerged as an indispensable material across a diverse range of applications. In the realm of prototype model design, it allows designers to bring their concepts to life with exceptional precision, capturing every intricate detail. For PVC plastic mold creation, it serves as a reliable base, ensuring the production of high - quality plastic components with consistent shapes and dimensions. In the construction industry, it is employed to fabricate molds for cement products, enabling the creation of customized architectural elements. When it comes to alloy mold making, prototyping silicone's ability to withstand high temperatures and maintain its structural integrity makes it suitable for melting point alloy molds. It plays a crucial role in the production of alloy toy crafts and plastic toy crafts, facilitating the mass production of detailed and durable toys. In the field of gift stationery, it helps create unique and intricate designs. For large statues and the reproduction of cultural relics, it ensures accurate replication, preserving historical and artistic details. Additionally, in shoe sole mold manufacturing, it offers the flexibility to produce soles with diverse patterns and textures. It is also utilized for pad printing positioning, providing stability and accuracy. Moreover, its shock - absorbing properties make it an ideal choice for enhancing the shock resistance of electronic equipment, protecting sensitive components from damage during transportation and operation.

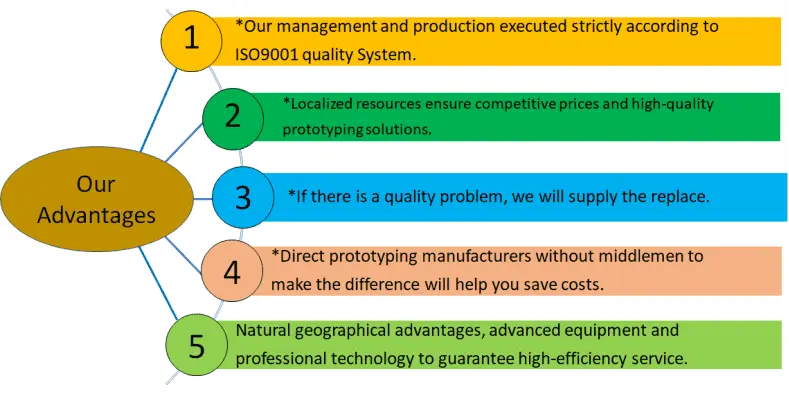

Advantages

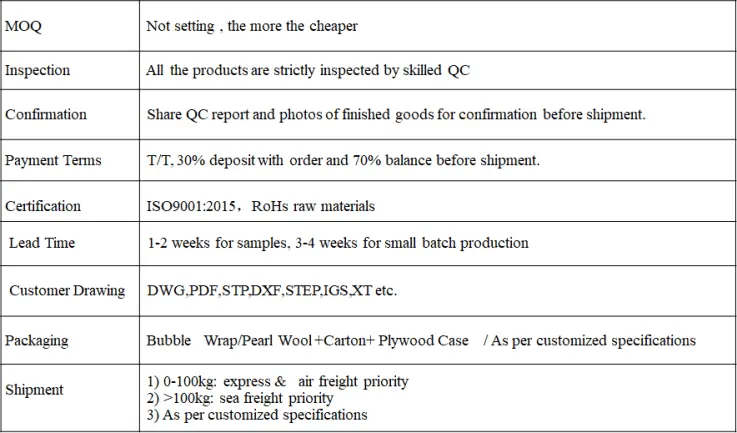

Delivery Information

FAQs

Q1. What kind of product quality your factory offers?

A1: We offer high precision, good appearance, most competitive prices with best quality.

Q2: Do you accept OEM and ODM business?

A2: We accept OEM and ODM with your authorization.

YOU MAY LIKE

_1744788508965.png)