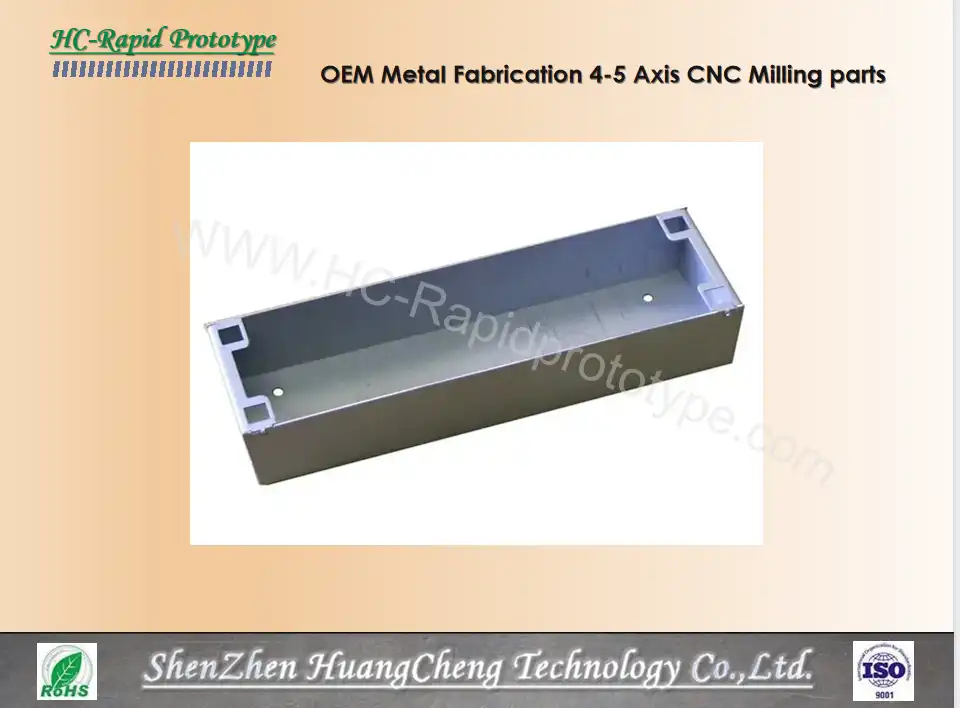

Product Details:

Material: Stainless steel , Carbon steel, Alloy steel etc.

Surface Treatment: Sand blasting, Color anodizes, Brushing, Polishing, Plating, painting etc.

Processing Method: CNC machining, CNC milling, drilling, Tapping.

Application Industry: Agriculture machinery, food processing and packing machine

Tolerance: Refer to ISO 2768-m or customer drawings request.

Introduction:

We are China Supplier who providing High Precision CNC Milling Parts made by CNC Milling to USA , European and other markets, these mechanical components are widely applying into agriculture machinery, food processing and packing machine. More other CNC Machine parts can be customized, and your drawings will be quoted within 8 hours, welcome to contact our service team to get a free quotation and discuss which machining process is the most efficient and suitable one for your project.

*More High Precision CNC Milling Parts for your review

Key Advantages for Your Industry:

Aerospace & Defense

- Ultra-precise engine components and avionics housings with full material traceability.

- AS9100-compliant processes for mission-critical parts.

Medical Devices

- Biocompatible, sterilizable parts for surgical tools and implants.

- Cleanroom machining for ISO Class 7 standards.

Automotive & EV Systems

- High-volume production of transmission parts and battery housings.

- Lightweight designs to improve energy efficiency.

Industrial Machinery

- Custom gears, valves, and hydraulic components built for heavy-duty use.

Our Production Process: Precision at Every Stage:

- Design Review: Free DFM analysis to optimize manufacturability and cost. Our team of experts conducts a complimentary Design for Manufacturability (DFM) analysis, meticulously examining your designs. We identify potential issues, suggest improvements, and streamline processes to enhance manufacturability and reduce production costs.

- Material Selection: Locally sourced raw materials to reduce lead times. To ensure efficiency, we prioritize locally sourced raw materials. This strategic approach minimizes transportation delays and supply chain disruptions, significantly reducing lead times and getting your products to market faster.

- CNC Machining: 5-axis milling centers with real-time quality monitoring. Our advanced 5-axis milling centers are equipped with real-time quality monitoring systems. These systems continuously assess the machining process, ensuring precision and quality control at every stage of production.

- Post-Processing: Deburring, heat treatment, or custom finishes. After machining, we offer a range of post-processing services, including deburring to smooth edges, heat treatment to enhance material properties, and custom finishes to meet your specific aesthetic and functional requirements.

- Final Inspection: CMM testing and ISO-compliant documentation. Before delivery, each product undergoes a thorough final inspection using Coordinate Measuring Machines (CMM). We also provide ISO-compliant documentation, ensuring full traceability and quality assurance for your peace of mind.

Why Choose ShenZhenHuangCheng?

- Rapid Prototyping: Test designs faster with 3-day sample delivery. Leveraging advanced 3D printing and agile manufacturing processes, our rapid prototyping service enables you to quickly visualize and test your designs. We guarantee a swift 3-day sample delivery, accelerating your product development cycle.

- Cost Efficiency: Competitive pricing for LTAs (Long-Term Agreements). Through strategic cost management and economies of scale, we offer highly competitive pricing for Long-Term Agreements. This allows you to secure consistent quality at reduced costs over extended periods.

- Supply Chain Resilience: Dual sourcing and inventory management support. To safeguard against disruptions, we implement dual sourcing strategies and provide comprehensive inventory management. This ensures a reliable supply of materials and parts, enhancing your supply chain resilience.

- 24/7 Engineering Support: Collaborate directly with our technical team. Our dedicated engineering experts are available around the clock to provide immediate support. Whether it’s design advice or troubleshooting, you can collaborate directly with our skilled team at any time.

Comment and Delivering:

FAQs:

Q1: What is the standard of package?

A1: Professional export packing:

1)Separate Blister plastic box or Bubble Wrap/Pearl Wool, keep no scratch and damage.

2)Under 100 KGS parts, use strong DHL export Carton .

3)Above 100 KGS, will customize Wooded case for packing.

Q2: How to ship High Precision CNC Milling Parts ?

A2: 1)Normally, we shipped the goods by DHL,FEDEX,UPS,TNT express. 2-3 days can arrived the clients' company directly.

2)For heavy parts, can shipped by air or by sea according to customers’ indication.

YOU MAY LIKE

_1744788508965.png)