Product Details

|

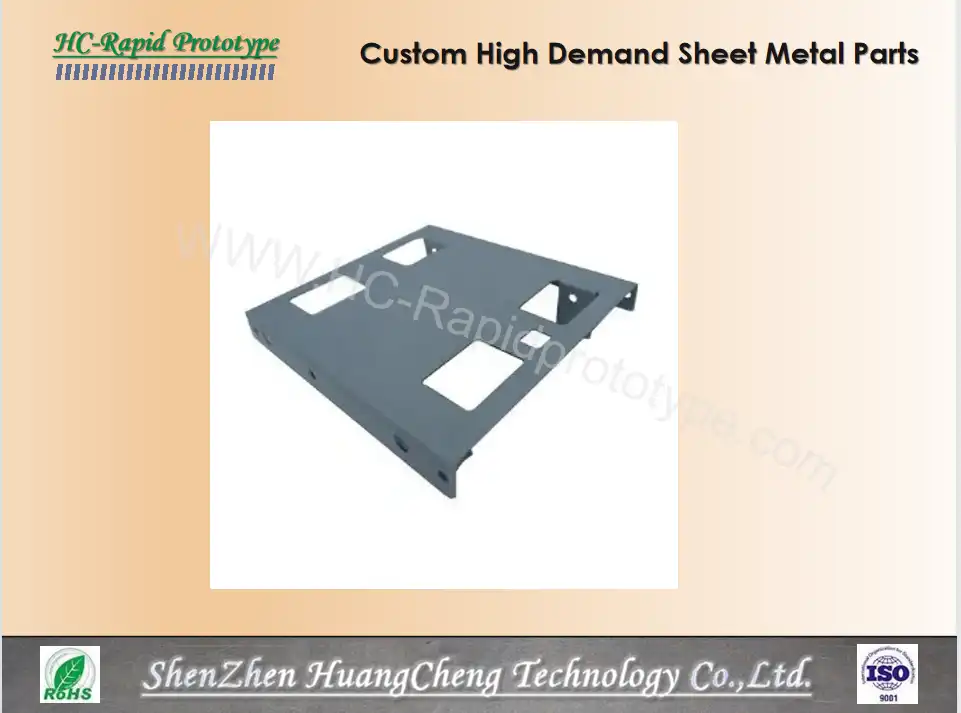

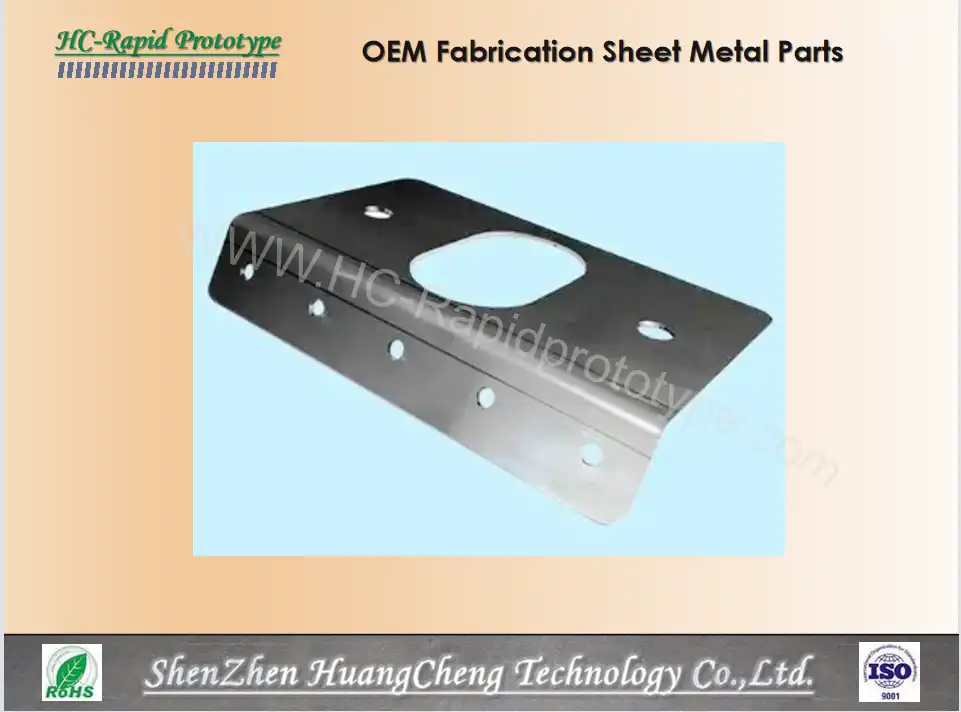

Product |

Metal-rubber overmold vacuum casting parts |

|

Size |

Customized dimensions |

|

Color |

Customized |

|

Material |

Metal , brass , copper , stainless , steel, aluminum alloy, rubber |

|

Surface finish |

Polishing, painting, silk screen etc. |

Deliverty Information

Introduction

Metal-rubber overmold vacuum casting parts represent an innovative and precise manufacturing solution. The process begins with utilizing the client's golden sample or a meticulously crafted prototype developed strictly in accordance with customer-provided drawings. This initial model serves as the foundation for generating a highly accurate silicone mold, which captures every intricate detail of the original design. Subsequently, the metal components are expertly fabricated through either the Computer Numerical Control (CNC) machining process, renowned for its high precision and repeatability, or the cutting-edge 3D printing technology, offering flexibility in complex geometries. Once the metal parts are ready, the next crucial step involves pouring rubber-like materials into the silicone mold under a vacuum state. This vacuum environment ensures that the material fills the mold completely, eliminating air bubbles and achieving a flawless finish, thereby reproducing an identical replica of the original golden sample or prototype. If clients require different colors, specialized pigments can be seamlessly incorporated into the raw material, allowing for customization to meet diverse aesthetic demands. This method combines the durability of metal and the flexibility of rubber, making it ideal for producing functional and visually appealing parts for various industries.

Advantages

Metal-rubber overmold vacuum casting parts is a low-cost yet highly reliable technique for crafting high-quality prototypes in small batches using original models. It eliminates the need for expensive tooling, significantly cutting down initial investment. The process ensures excellent replication of details, delivering consistent and accurate results. Ideal for rapid prototyping, it enables quick production for engineering testing, validating proof of concept, and effectively demonstrating model designs with efficiency and precision. The advantages are following:

● Low initial cost as no investment in tooling is required, making it an ideal choice for startups with tight budgets. This allows new businesses to kickstart production without the heavy financial burden of expensive molds, conserving capital for other critical aspects.

● The mold is high-fidelity, making the surface details perfect, and basically no post-processing is required, saving both time and labor costs significantly. From intricate textures to fine engravings, the final product emerges ready-to-use, streamlining the manufacturing workflow.

● With a wide variety of different model polymers available, it can be colored to meet your specific color requirements, enabling personalized product designs. Whether it's a vibrant hue for marketing purposes or a specific shade to match branding, customization is at your fingertips.

● Once the master model is created, the mold can be made in a few days, greatly shortening the time from design to production. This rapid turnaround allows companies to quickly adapt to market demands and get products to customers faster.

● Dies can last up to 50 times, so if you need multiple copies, this cost-effective solution is highly beneficial for small-batch production. It offers an economical way to produce limited runs without sacrificing quality or incurring excessive costs.

● We provide multiple molding methods, allowing plastics of different hardness to be molded into the same mold, enhancing design flexibility. This versatility enables the creation of complex, multi-material products with diverse mechanical properties.

● For rapid product development, this is a great option for testing multiple variables of the model design, accelerating the iteration process. By quickly producing and evaluating prototypes, companies can refine designs and bring improved products to market more efficiently.

Product Characteristics:

● Excellent vibration and shock absorption, effectively protecting internal components from damage during transportation and operation, ensuring the stability and reliability of equipment.

● Superior sealing properties prevent leakage of liquids, gases, and dust, providing a secure and clean environment for various applications, reducing the risk of contamination and failure.

● High durability and wear resistance mean it can withstand harsh working conditions and continuous use, extending service life and minimizing replacement frequency and maintenance costs.

● Precise dimensional accuracy ensures a perfect fit with other parts, enhancing assembly efficiency, reducing errors, and improving the overall performance of the final product.

● Corrosion resistance allows it to maintain integrity in corrosive environments like coastal areas or chemical plants, avoiding degradation and ensuring long - term stable operation.

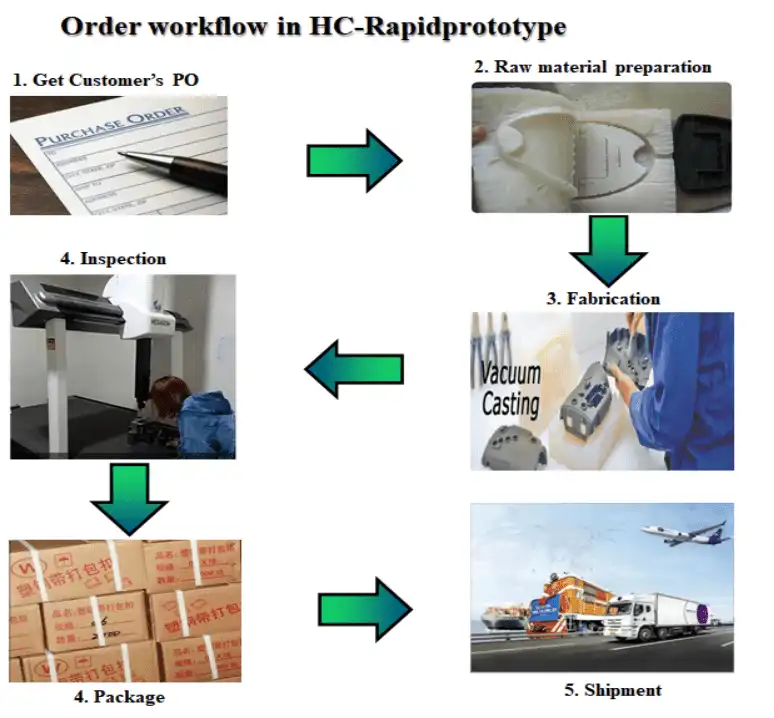

HC Workflow

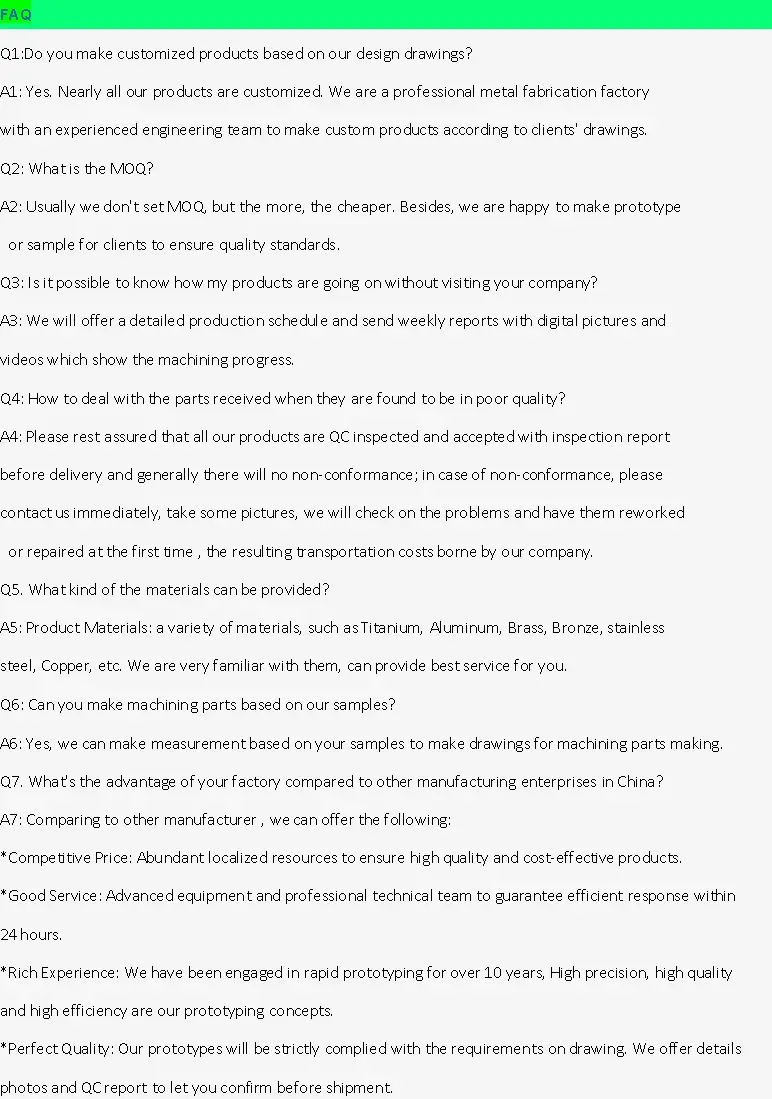

FAQ

YOU MAY LIKE

_1744788508965.png)