Product Details:

|

Product Name |

CNC Turning and Milling Metal Parts |

|

Size |

Refer to drawing or customer additional request |

|

MOQ |

1 piece, Unit price depend on sample quantity |

|

Materials |

Steel, Stainless Steel or other metals. |

|

Surface Finish |

Plating, Anodized or customized |

|

Tolerance |

Refer to ISO 2768-m or customer specification |

|

Accuracy |

0.01mm-0.05mm |

|

Application |

Industrial Equipment, aerospace, auto parts etc. |

Introduction:

Machine tool compounding is one of the important directions of machine tool development. Compound machine tools include turn milling compound, cutting and 3D printing compound, cutting and ultrasonic vibration compound, laser and stamping compound and other forms. The purpose of compound is to make a machine tool multifunctional, complete multiple tasks at one time, and improve machining efficiency and machining accuracy.

*More CNC Turning and Milling Metal Parts for review

Key Characteristics of Our CNC Metal Parts :

- Durability: Components withstand harsh environments, ideal for aerospace or energy applications. Our components are engineered using high-grade materials and advanced manufacturing techniques, enabling them to endure extreme temperatures, high pressures, and corrosive atmospheres, making them a perfect fit for demanding aerospace and energy sector requirements.

- Precision: Achieve micron-level accuracy for critical assemblies. With state-of-the-art equipment and strict quality control measures, we can consistently deliver CNC Turning and Milling Metal Parts with micron-level precision, ensuring seamless integration and optimal performance in even the most critical and complex assemblies.

- Customization: Tailored finishes, materials, and tolerances to match your blueprints. Our team works closely with you to understand your specific needs, offering customized solutions that cover a wide range of finishes, material options, and tolerance specifications precisely as per your detailed blueprints.

Our Production Process :

- Design Review: Collaborate with your engineers to optimize designs for manufacturability. Our team of experienced design experts partners closely with your engineers, analyzing every aspect of the design. Through in - depth discussions and technical evaluations, we identify areas for improvement to ensure seamless production while reducing costs and time.

- Material Selection: Source certified metals for performance and sustainability. We prioritize both the performance requirements of your project and environmental responsibility. Our extensive network enables us to source only certified metals that meet strict quality standards, guaranteeing durability and contributing to sustainable manufacturing practices.

- Machining: Utilize 5-axis CNC milling and turning for complex geometries. Harnessing the power of advanced 5-axis CNC milling and turning machines, we can effortlessly handle intricate and complex part geometries. This technology allows for greater precision, faster production times, and the ability to create parts that meet the most demanding specifications.

- Quality Assurance: Rigorous CMM checks and surface finish inspections. Our quality assurance process is comprehensive, involving precise Coordinate Measuring Machine (CMM) checks to verify dimensional accuracy and meticulous surface finish inspections. These rigorous evaluations ensure that each part meets the highest quality benchmarks before moving forward.

- Packaging & Delivery: Secure shipping with real-time tracking. We take great care in packaging your products to safeguard them during transit, using high-quality protective materials. Additionally, we provide real-time tracking services, allowing you to monitor the progress of your shipment every step of the way for peace of mind.

Why Choose ShenZhenHuangCheng Technology? :

- Technical Expertise: A team of skilled engineers providing real-time support for design adjustments. Our group of highly proficient engineers stands ready to offer immediate assistance, analyzing your design needs and making on - the - fly modifications to ensure optimal manufacturability.

- Scalability: From 50 prototypes to 50,000+ bulk orders, we adapt to your needs. With advanced production facilities and flexible workflows, we smoothly transition between small - scale prototyping and large - volume production, maintaining consistent quality throughout.

- Transparent Communication: Proactive updates on production milestones and logistics. We keep you informed every step of the way, providing regular, detailed updates on production progress, delivery schedules, and any potential challenges.

- Global Reach: Serving manufacturers in North America, Europe, and Asia with localized supply chain advantages. Leveraging our established networks across continents, we offer region - specific supply chain benefits, ensuring efficient service and timely delivery to clients worldwide.

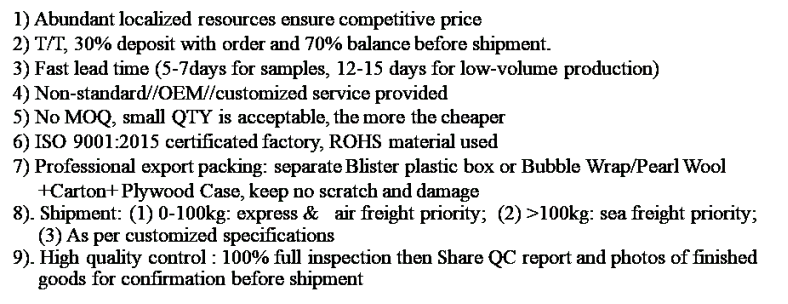

Our Advantages:

1. High precision production equipment to provide high-quality products.

2. Many kinds of surface treatment to meet your appearance requirements.

3. Rich processing expertise to offer accurate solution

4. Professional technical team to ensure efficient response

Package and shipment:

FAQs:

Q1. Can I get a quote without drawings?

A1: Of course, we are happy to receive your samples and sketches with detailed dimensions

Q2. How do you control quality in your company?

A2: We have a professional and mature quality control system. During the manufacturing process, professional quality inspectors will conduct sampling inspection. All products must pass the inspection before packaging and shipment .

YOU MAY LIKE

_1744788508965.png)