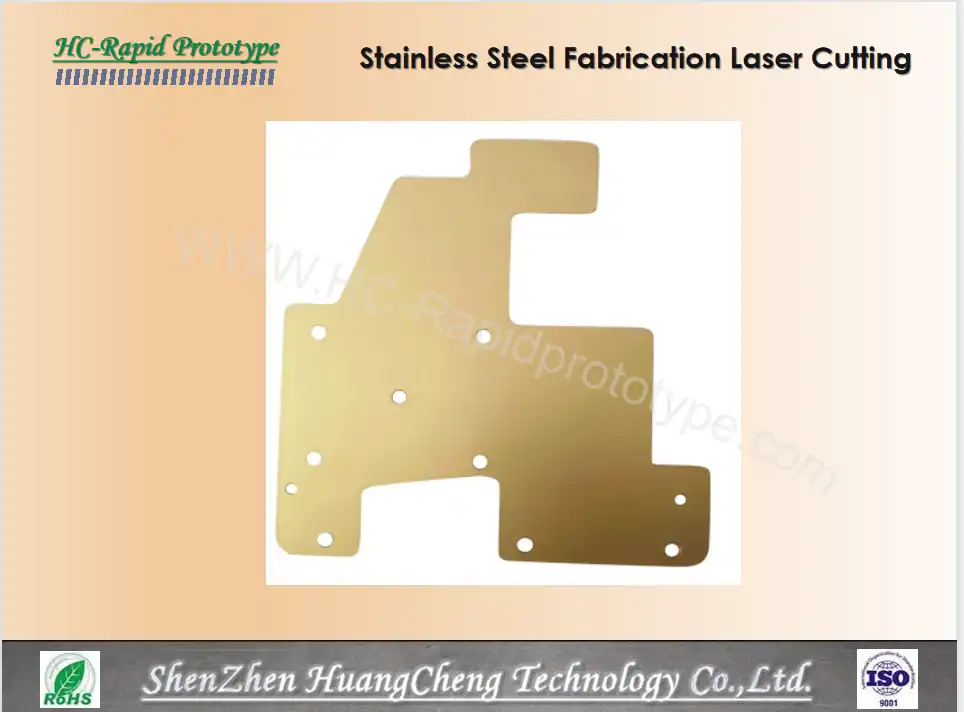

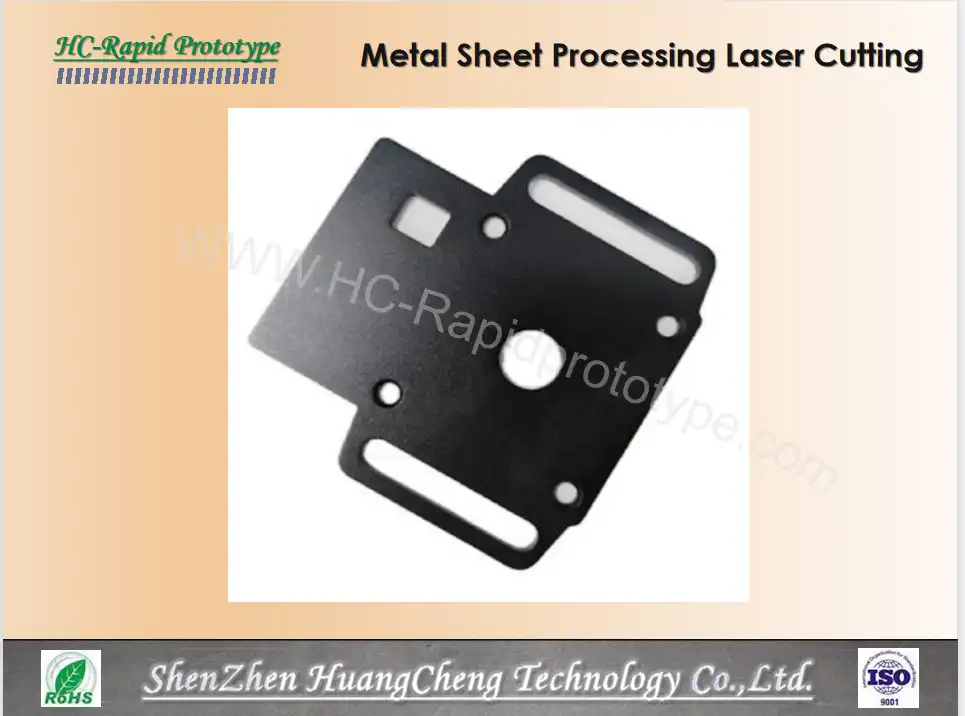

Product Details

The thickness that the laser cutting machine can cut is determined according to the power of the equipment:

A laser cutting machine with a power of 500 watts can cut sheets with a thickness of 4-5mm, a 1000w equipment can cut sheets with a thickness of 8-10mm, and a 2000w laser cutting machine can cut metal sheets with a thickness of 10-15mm. The plate comes up for Steel Part Processing Laser Cutting. There are also many types of equipment selected according to different specifications.

Introduction

When laser cutting steel, oxygen and a focused laser beam are injected into the material to be cut through a nozzle to form a gas stream. The basic requirements for airflow are that the airflow entering the incision should be large and the speed should be high, so that enough oxidation can make the incision material fully perform exothermic reaction; at the same time, there is enough momentum to blow the molten material out. Therefore, in addition to the quality of the beam and its control directly affecting cutting quality, the design of nozzle and the control of airflow (such as nozzle pressure, the position of workpiece in the airflow etc.) are also very important factors. The nozzle for laser cutting adopts a simple structure, that is, a tapered hole with a small round hole at the end. The design is usually done using an experiment and error method.

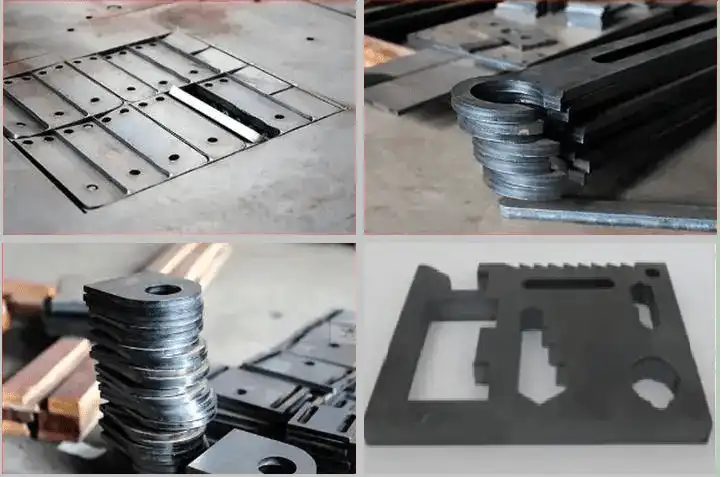

*Some Steel Parts Processing by Laser Cutting for reference

Production Process:

1. CAD file preparation and optimization

2. Material selection and placement

3. Laser cutting using advanced CNC machines

4. Quality inspection and deburring

5. Post-processing (if required)

6. Packaging and shipping

Applications:

Our Steel Part Processing Laser Cutting services cater to diverse industries, including:

- Automotive components

- Aerospace parts

- Industrial machinery

- Construction elements

- Electronics enclosures

Why Choose ShenZhenHuangCheng Technology?

1. Expertise: Our team of skilled engineers and technicians brings years of experience to every project.

2. Advanced Technology: We invest in the latest laser cutting equipment to ensure superior results.

3. Customization: We offer tailored solutions to meet your specific requirements.

4. Quality Assurance: Rigorous quality control processes guarantee consistent, high-quality output.

5. Cost-Effectiveness: Our efficient processes and local sourcing help keep costs competitive without compromising quality.

Advantage

Compared with common traditional cutting processes (such as water cutting, EDM, gas-fuel cutting, plasma cutting, die punching, saw cutting, wire cutting, laser cutting etc.). Laser processing has outstanding advantages as a whole! Whether in terms of accuracy, speed, or cost, the advantages of laser processing are obvious. And it is much easier to change graphics than other processing methods. From this point of view, laser processing is an indispensable processing method in modern industrial production.

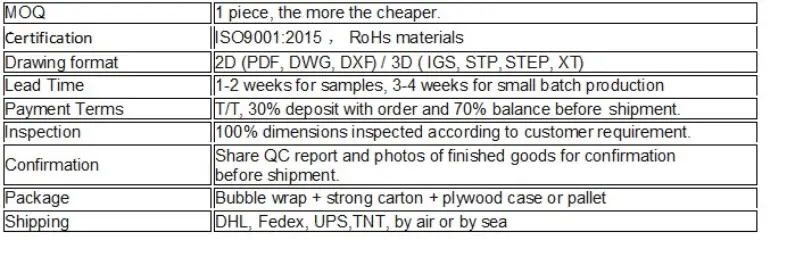

Delivery Information

FAQs

Q: What is the minimum order quantity for Steel Part Processing Laser Cutting?

A: We accommodate various order sizes, from prototypes to large production runs. Contact us for a custom quote.

Q: Can you handle rush orders?

A: Yes, we offer expedited services for urgent projects. Please discuss your timeline with our sales team.

Q: Do you provide design assistance for optimizing parts for laser cutting?

A: Absolutely. Our engineering team can review your designs and suggest optimizations for improved efficiency and cost-effectiveness.

Q: What materials can you laser cut besides steel?

A: While we specialize in steel, we can also process aluminum, titanium, and other metals. Contact us for specific material inquiries.

Q: How do you ensure consistent quality across large production runs?

A: We employ advanced quality control measures, including in-process inspections and statistical process control, to maintain consistency throughout production.

YOU MAY LIKE

_1744788508965.png)