Product Details

|

Product Name |

Machining Laser Cutting Plastic Parts |

|

Size |

Customized dimensions |

|

Color |

Natural |

|

MOQ |

1 piece |

|

Material |

Plastic |

|

Customer Drawing |

2D (PDF/ DWG/ DXF) & 3D (IGS/ STP/STEP/XT) |

Delivery

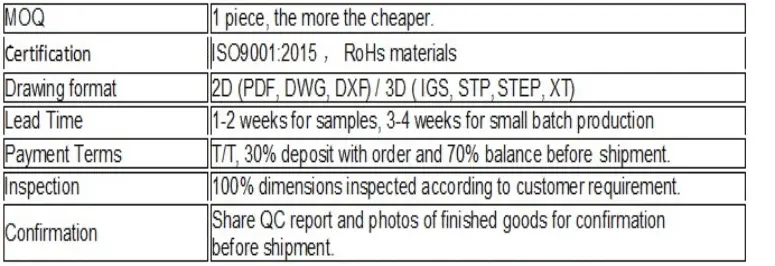

Below table shows the information about delivery /payment terms and MOQ for the finished goods , please check it for details.

Introduction

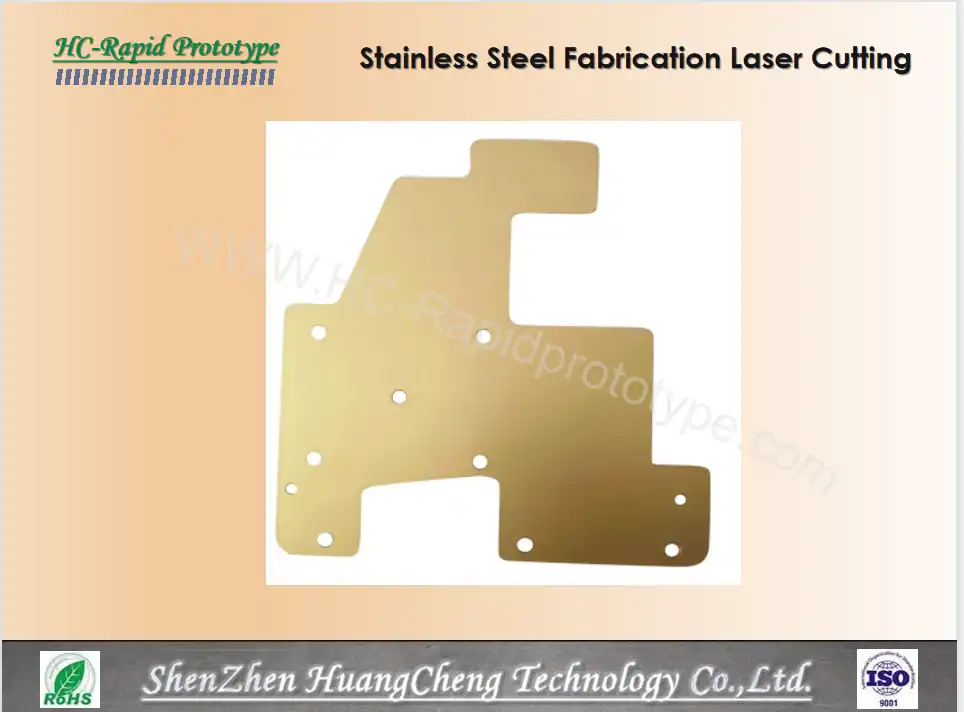

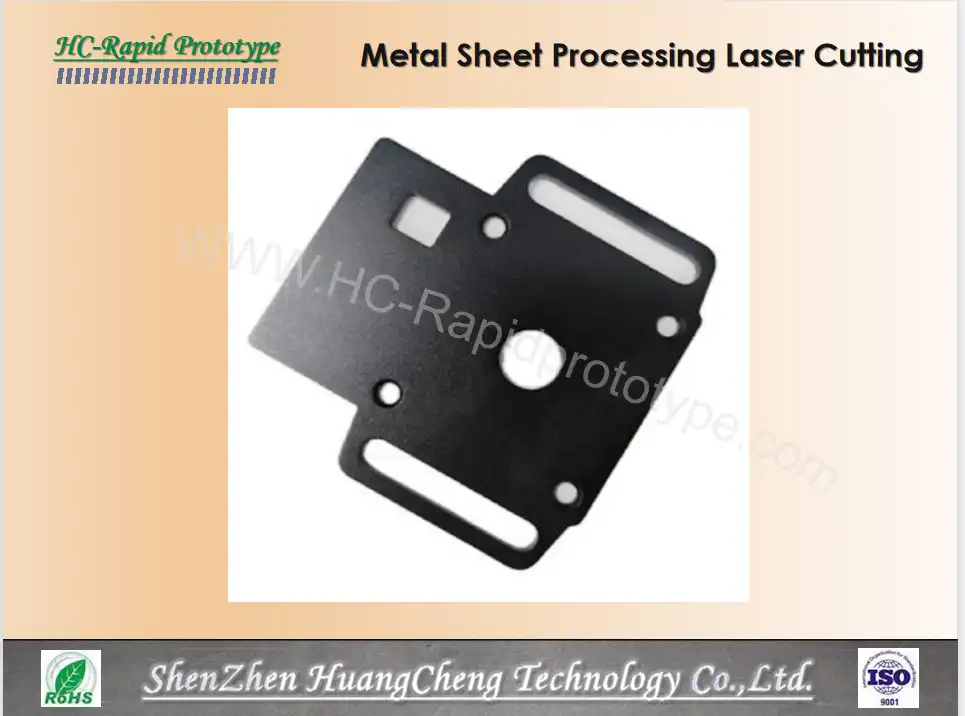

Machining Laser Cutting Plastic Part technology is widely used in the processing of metal and non-metal materials, which can greatly reduce processing time, reduce processing costs and improve workpiece quality. Pulsed laser is suitable for metal materials, continuous laser is suitable for non-metallic materials, and plastic is an important application field of laser cutting technology. The modern laser has become the "sword" that people fantasize and pursue to "cut iron like mud".

HC-Rapidprototype Advantage:

- Rapid turnaround times: We understand the importance of time in business. Our streamlined production processes and efficient workflows enable us to complete orders promptly, ensuring you receive your products without delay, even for urgent requirements.

- Competitive pricing: By optimizing our supply chain, leveraging economies of scale, and improving production efficiency, we offer highly competitive prices. You'll get top - quality products at costs that give you an edge in the market.

- Customization capabilities: Every client has unique needs. Our experienced team works closely with you to develop tailored solutions. Whether it’s design, functionality, or specifications, we can customize products to fit your exact requirements.

- Comprehensive quality control: From raw material inspection to final product testing, our multi - layer quality control system leaves nothing to chance. Rigorous checks at every stage ensure that only products meeting the highest standards are delivered to you.

Product Feature and Application

Machining Laser Cutting Plastic Parts can apply to automotive, motorcycle, machinery, bicycles, medical devices, sporting equipment, scientific equipment, electronics.

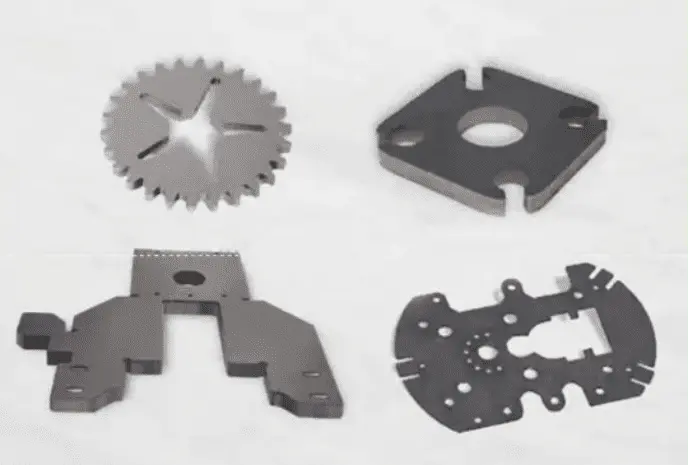

*Similar Machining Laser Cutting Small Plastic Parts For reference

Production Process:

- CAD file analysis and optimization: Our team of experts thoroughly analyzes the CAD files to identify potential design flaws or areas for improvement. We optimize the files to ensure seamless compatibility with our manufacturing processes, enhancing efficiency and reducing errors.

- Material selection: Based on the specific requirements of your project, we carefully select the most suitable materials. Considering factors such as strength, durability, and cost, we source high - quality materials that meet industry standards and your exact needs.

- CNC machining or laser cutting: Utilizing state - of - the - art CNC machines or laser cutting equipment, we precisely transform the selected materials into the desired shapes. Our advanced technology and skilled operators guarantee accurate and consistent results for every part.

- Quality inspection: A team of experienced inspectors conducts a comprehensive quality inspection at this stage. Using advanced measuring tools and techniques, they check for dimensional accuracy, surface finish, and overall quality to ensure each part meets our strict standards.

- Post - processing (if required): When necessary, we perform post - processing operations such as deburring, polishing, or heat treatment. These steps enhance the functionality, appearance, and performance of the parts, ensuring they are ready for use.

- Final quality check and packaging: Before packaging, we conduct a final quality check to double - confirm that all parts are in perfect condition. We then carefully package the products using protective materials to prevent damage during transit and ensure they reach you in pristine condition.

Packaging ,Express and Shipment

1. Packaging : Bubble Wrap/Pearl Wool + Strong Carton + Plywood case

2. Support Express DHL, Fedex , UPS, TNT ect.

3. Shipping: Sea freight, Land freight and Air freight.

FAQs

Q1: Will you be able to work with our engineering team to review drawings and provide quick, estimated pricing for desired changes?

A1: Yes, our engineering technicians respond very quickly. If there is anything to be modified in the product, we can offer you a

new price as soon as you tell us.

Q2: How to enjoy the OEM services?

A2: Usually, based on your design drawings or original samples, we give some technical proposals and a quotation to you,

after your agreement, we produce for you.

YOU MAY LIKE

_1744788508965.png)