Product Details

|

Product Name |

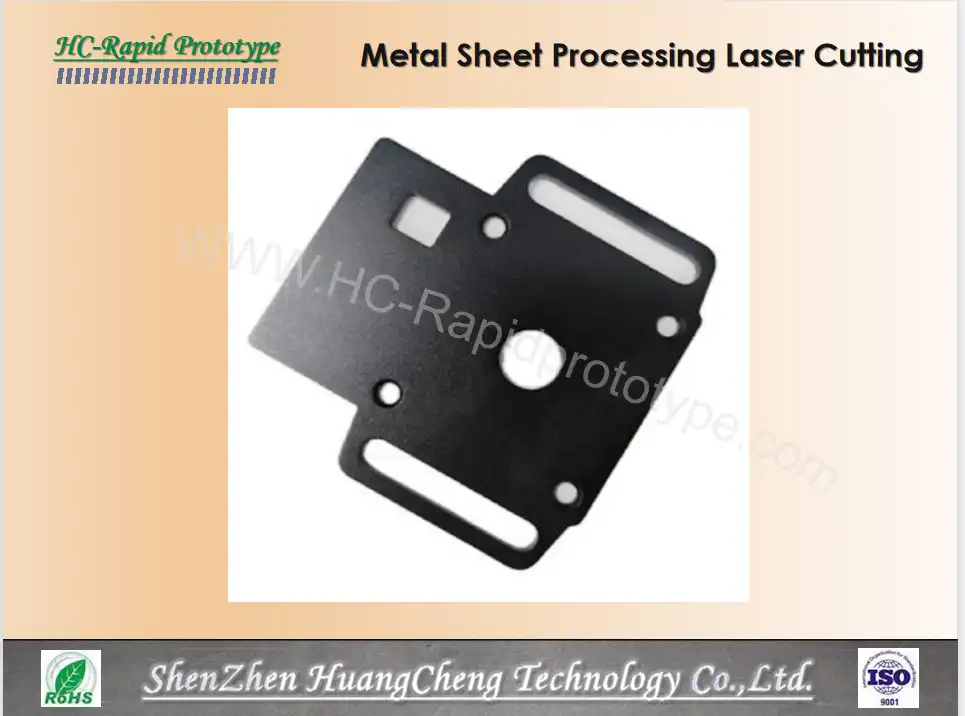

Metal Sheet Processing Laser Cutting |

|

Size |

Defined by customer |

|

Tolerance |

0.01-0.05mm |

|

Certification |

ISO9001:2015 |

|

MOQ |

1pcs |

|

Drawing Format |

2D(DWG/DXF), 3D(IGE/STEP) |

Introduction

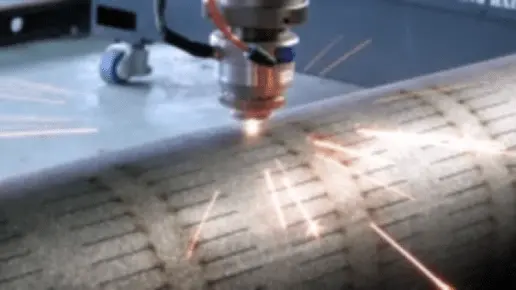

Laser is the use of material excitation to generate light. This light has a strong temperature. When it contacts the material, it can quickly melt on the surface of material to form punching holes. Compared with traditional cutting method, the cutting method has a smaller gap and can save most of the material. However, the analysis is defined according to cutting effect. of according to laser cut material ,The cutting effect can be satisfactory, and the accuracy is high. This is inherited With the advantages of laser, it is also unmatched by ordinary cutting methods.

Lasers can be cut on multi-product materials, such as acrylic, knife templates, fabrics, leather, metals and other industries can use lasers for cutting, so laser cutting is a new solution for cutting in multiple industries.

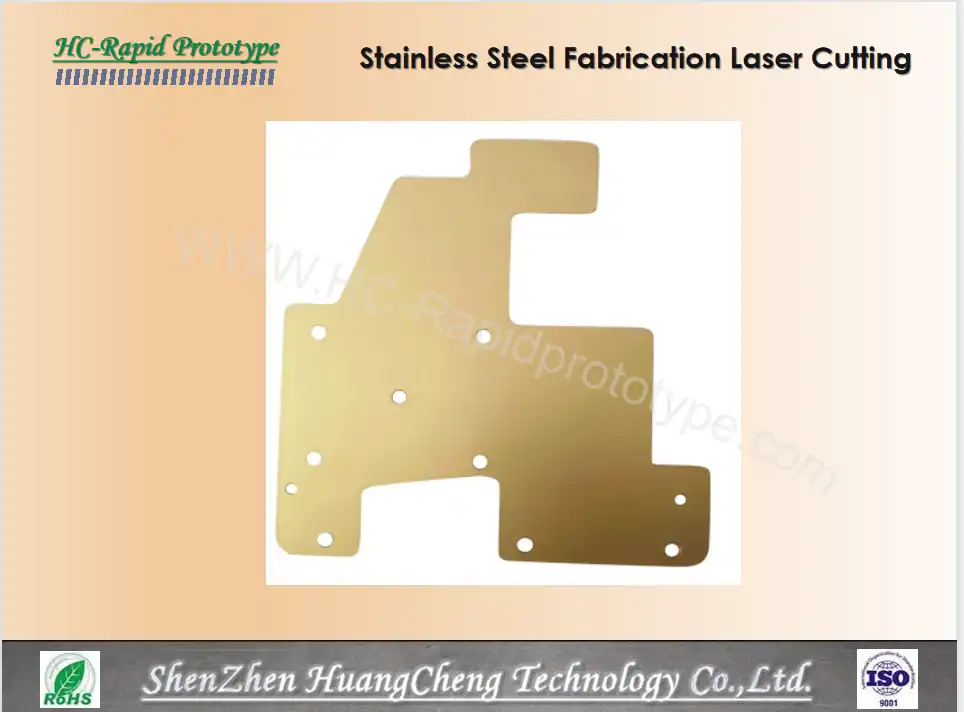

*Some Metal Sheet Processing Laser Cutting parts for reference

Product Characteristics:

- High-precision cuts: Our advanced cutting technology utilizes state-of-the-art equipment and precise programming to achieve highly accurate cuts. With micron-level precision, every cut adheres strictly to design specifications, ensuring parts fit seamlessly in complex assemblies.

- Smooth edges: Employing specialized finishing techniques and optimized cutting parameters, we produce parts with flawlessly smooth edges. This not only enhances the aesthetic appeal but also eliminates sharp edges that could pose safety risks or cause damage during use.

- Minimal material waste: Through intelligent nesting algorithms and efficient cutting strategies, we maximize material utilization. By closely packing parts and minimizing scrap, we reduce waste, cut costs, and contribute to more sustainable manufacturing practices.

- Consistent quality across large production runs: Rigorous quality control protocols and automated production systems work in tandem to maintain uniform quality throughout extensive manufacturing batches. Every part, regardless of batch size, meets the same exacting standards.

- Complex shape capabilities: Our cutting equipment, combined with skilled operators and advanced software, can handle the most intricate designs. From elaborate geometric patterns to detailed contours, we bring complex shapes to life with precision and reliability.

Production Process:

- CAD file preparation: Our experts meticulously review and optimize CAD files, ensuring all design details are accurate and compatible with our manufacturing systems. We make necessary adjustments for a seamless production process.

- Material selection and preparation: Based on project requirements, we carefully choose the most suitable materials. Then, we prepare them by cleaning, sizing, and ensuring they are ready for the laser cutting stage.

- Laser cutting: Using high - tech laser cutting machines, we precisely cut materials according to the CAD design. The automated process ensures accuracy and consistency in every cut.

- Quality inspection: A team of skilled inspectors conducts thorough checks on all cut parts. They verify dimensions, edge quality, and overall integrity to meet strict quality standards.

- Post - processing (if required): For parts that need additional refinement, we perform post - processing steps like deburring, polishing, or bending to enhance functionality and appearance.

- Packaging and shipping: We carefully package finished parts to prevent damage during transit. Then, we arrange for prompt shipping, providing tracking information for your peace of mind.

Applications:

Our Metal Sheet Processing Laser Cutting services cater to various industries, including:

- Automotive parts manufacturing: In automotive parts manufacturing, we produce high - quality components ranging from robust engine parts to aerodynamic body panels. Precision machining ensures these parts enhance vehicle performance and safety.

- Aerospace component production: For aerospace component production, we fabricate lightweight yet incredibly strong parts. Using advanced materials and techniques, we meet stringent industry standards for flight - critical components.

- Electronics enclosures: When creating electronics enclosures, we focus on combining functionality with protection. Our designs ensure proper ventilation, electromagnetic shielding, and secure housing for sensitive circuitry.

- Construction and architectural elements: In construction and architectural elements, we craft durable and aesthetically pleasing structures. From decorative metal facades to structural steel components, our work adds value to buildings.

- Industrial machinery fabrication: Industrial machinery fabrication involves building reliable and efficient equipment. We use heavy - duty materials and precise manufacturing to create machinery that can withstand tough industrial environments.

Competitive advantage

1. Respond quickly and keep pace with the customer's time.

2. Skilled Q & A and considerate service.

3. Product manufacturing will be followed up by professionals.

4. Excellent product management and quality control ensure efficient delivery to customers.

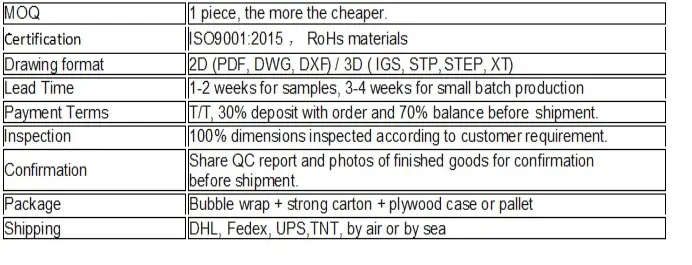

Delivery

The delivery terms for your reference

FAQ

Q1: Where can I get product & price information?

A1: Send us e-mail, we will contact you as we receive your email.

Q2: Is it possible to know how my products are going on without visiting your company?

A2: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Sent Message

YOU MAY LIKE

_1744788508965.png)