Product Details

|

Name |

Good Quality Sheet Metal Laser Cutting |

|

Size |

Refer to customized size |

|

Color |

Defined by customer |

|

Material |

Sheet Metal |

|

MOQ |

Low quantity is acceptable |

|

Tolerance |

ISO 2768-m |

Introduction

The precision and edge quality of laser-cut materials significantly outshine those achieved by conventional cutting methods. Laser cutting operates by utilizing an intensely focused beam of light. During the cutting process, this beam creates a relatively small heat-affected zone, which means it does not inflict extensive thermal damage on the adjacent surfaces. This characteristic is crucial, especially when working with materials that are sensitive to heat. Moreover, in the laser cutting process, high-pressure gas, typically CO2, plays a vital role. It forcefully injects molten material, effectively removing the material kerfs from narrower workpieces. As a result, for complex shapes and intricate designs, laser cutting delivers cleaner machining and smoother, more refined edges. The laser cutting machine is equipped with a computer numerical control (CNC) function, enabling the entire laser cutting process to be automatically governed by a pre-designed machine program. This CNC control system streamlines the operation, reducing the likelihood of human error on the part of the operator. Consequently, it allows for the production of more precise and accurate parts, with tolerances that are much tighter than what traditional cutting methods can achieve.

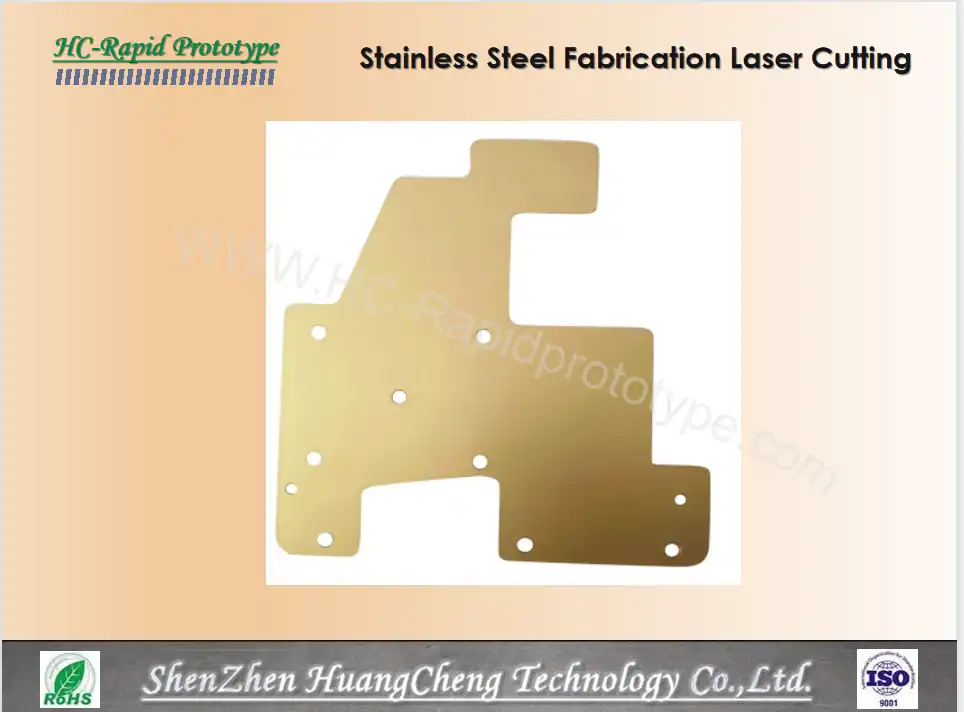

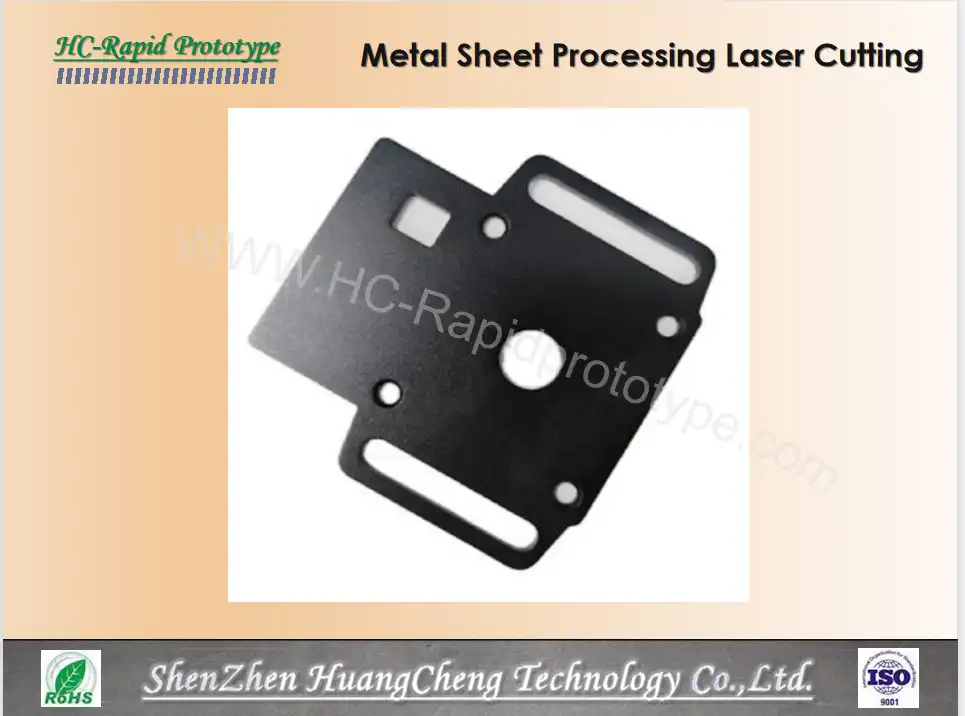

*Some Good Quality Sheet Metal Laser Cutting parts were listed as below.

HC-Rapidprototype Advantage and Service:

- Rapid turnaround times: We understand the urgency of your projects. With streamlined processes and efficient workflows, we ensure quick delivery without compromising on quality, getting your products to you in record time.

- Competitive pricing: Our strong supply chain and optimized production methods enable us to offer highly competitive prices. You'll receive top - notch products at costs that won't break your budget.

- Customized solutions: Every client has unique needs. Our team works closely with you to develop tailor - made solutions, ensuring that the final product perfectly aligns with your specific requirements.

- Comprehensive quality control: From raw material inspection to final product testing, our multi - stage quality control system leaves no room for error. We guarantee consistent, high - quality output every time.

- Expert technical support: Our knowledgeable technical team is always on standby. Whether it's answering queries, troubleshooting issues, or providing advice, we offer dedicated support throughout your project.

Product Characteristics:

- High precision cuts: Leveraging advanced cutting technologies, we achieve pinpoint accuracy in every cut. This ensures that parts meet exact specifications, crucial for complex assemblies and tight - tolerance applications.

- Smooth edges: Our cutting and finishing processes result in flawlessly smooth edges. This not only enhances the aesthetic appeal but also eliminates sharpness risks, making parts safer and more refined.

- Minimal material waste: Through optimized cutting algorithms and efficient nesting techniques, we maximize material utilization. This reduces waste, cuts costs, and promotes sustainable manufacturing practices.

- Consistency across large production runs: Rigorous quality control and automated processes guarantee uniform quality throughout large - scale production. Each part maintains the same high standard, ensuring reliable performance.

- Ability to create complex designs: With state - of - the - art equipment and skilled craftsmanship, we can bring intricate designs to life. No matter how complex the shape or pattern, we deliver precisely engineered parts.

Comment

1. Respond quickly and keep pace with the customer's time.

2. Skilled Q & A and considerate service.

3. Product manufacturing will be followed up by professionals.

4. Excellent product management and quality control ensure efficient delivery to customers.

Application

Good Quality Sheet Metal Laser Cutting has a wide range of uses in the medical industry, including medical production equipment and equipment, cutting precision tubing, and surgical applications that require sterile and precise cuts. The resulting smaller heat-affected zone reduces the amount of material wasted, thereby reducing overall costs, and the non-contact nature reduces the risk of workplace injuries and accidents. Faster programming and changeover times for laser cutting processes allow for greater production versatility while minimizing lead times.

Delivery

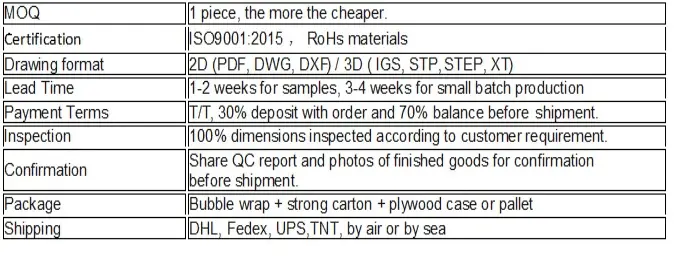

Our delivery terms are shown in below table.

FAQs

Q1: How do you make sure the price competitive based on the same quality?

A1. 1). Own factory assembly lines

2). Firsthand raw material sourcing

3). More than 10-year manufacturing experience

Q2. What is your delivery port?

A2. Our nearest port is Shenzhen port

YOU MAY LIKE

_1744788508965.png)