Product Details

|

Product Name |

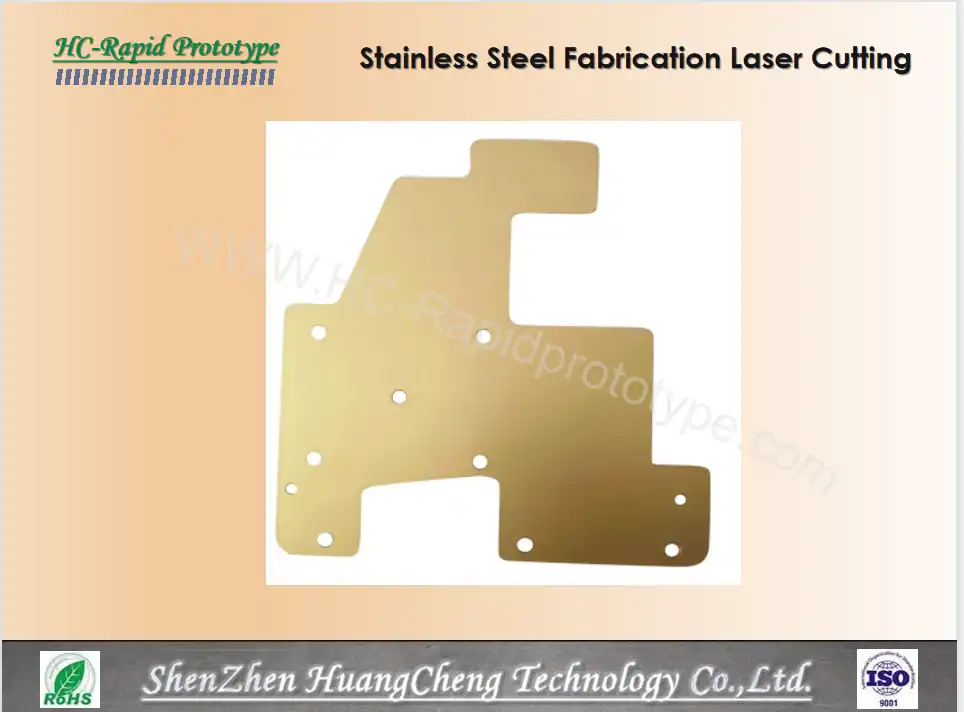

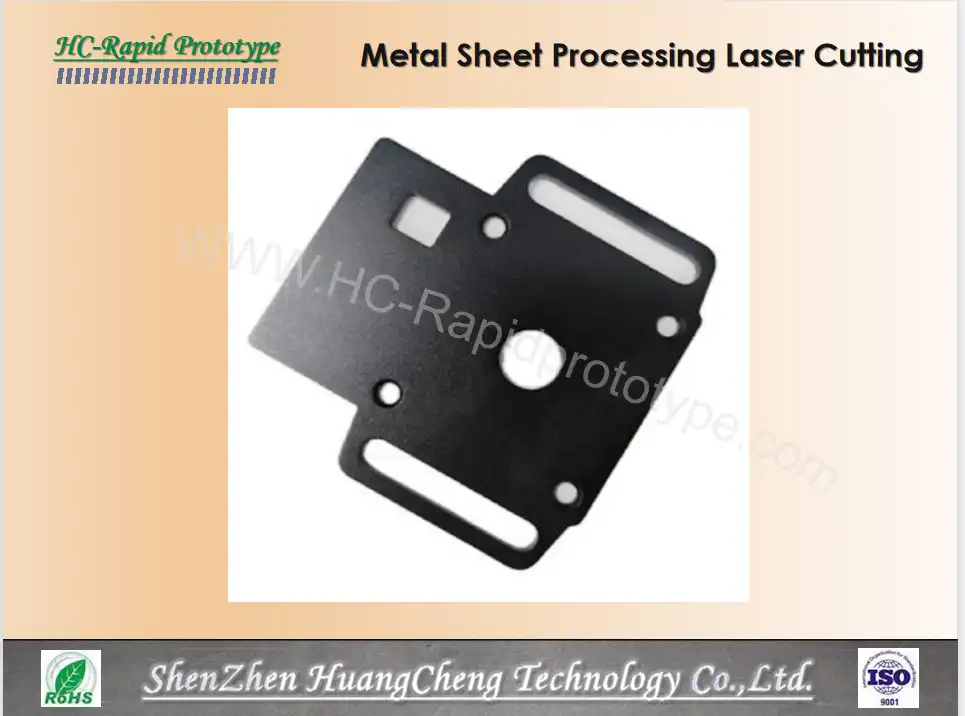

Sheet Metal Fabrication Laser Cutting |

|

Material |

Sheet Metal |

|

Surface Roughness |

Ra0.1 ~ 3.2 |

|

Tolerance |

0.01-0.05mm |

|

Keyword |

Laser Cutting |

|

Payment Terms |

T/T |

Introduction

Laser cutting can be divided into four categories: laser vaporization cutting, laser melting cutting, laser oxygen cutting and laser scribing and controlled fracture.

1) Laser vaporization cutting

A laser beam with high energy density is used to heat the workpiece, so that the temperature rises rapidly, reaching the boiling point of the material in a very short time, and the material begins to vaporize to form vapor. These vapors are ejected at a high velocity, and at the same time as the vapors are ejected, cuts are formed in the material. It is mostly used for cutting extremely thin metal materials and non-metal materials (such as paper, cloth, wood, plastic and rubber, etc.).

2) Laser melting cutting

When laser melting and cutting, the metal material is melted by laser heating, and then non-oxidizing gas (Ar, He, N, etc.) is sprayed through a nozzle coaxial with the beam, and the liquid metal is discharged by the strong pressure of the gas to form a cut. It is mainly used for the cutting of materials that are not easily oxidized or active metals, such as stainless steel, titanium, aluminum and their alloys.

3) Laser oxygen cutting

Laser oxygen cutting uses a laser as a preheating heat source and an active gas such as oxygen as a cutting gas. On the one hand, the blown gas interacts with the cutting metal to produce an oxidation reaction, releasing a large amount of oxidation heat; on the other hand, the molten oxide and melt are blown out from the reaction zone to form a cut in the metal. It is mainly used for easily oxidized metal materials such as carbon steel, titanium steel and heat-treated steel.

4) Laser scribing and controlled fracture

Laser scribing uses a high-energy-density laser to scan the surface of a brittle material, so that the material is heated and evaporated into a small groove, and then a certain pressure is applied, and the brittle material will crack along the small groove. Controlled fracture is the use of the steep temperature distribution produced by laser grooving to generate localized thermal stress in the brittle material, causing the material to break along the small groove.

*More Sheet Metal Fabrication Laser Cutting Parts for reference

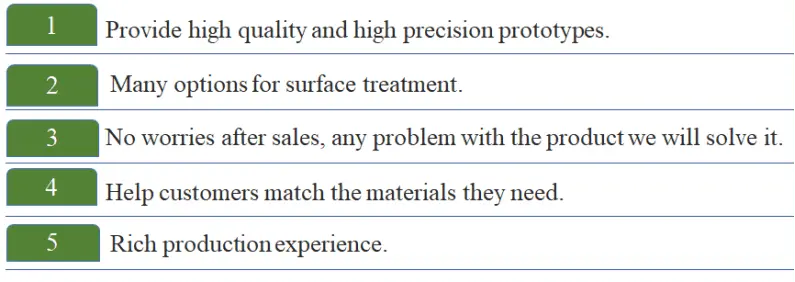

HC advantage

Product Characteristics:

- High precision cuts: Our advanced cutting technology utilizes state - of - the - art equipment and sophisticated software to execute cuts with unparalleled accuracy. This ensures that every part meets the most exacting dimensional requirements, enabling seamless integration in complex assemblies.

- Smooth edges: Through a combination of optimized cutting parameters and specialized finishing processes, we achieve flawlessly smooth edges on all our products. This not only enhances the aesthetic appeal but also eliminates potential safety hazards and improves functionality.

- Minimal material waste: Employing intelligent nesting algorithms and efficient cutting strategies, we maximize the utilization of raw materials. By minimizing scrap and off - cuts, we reduce costs and contribute to more sustainable manufacturing practices.

- Capability for intricate designs: With our cutting - edge machinery and skilled technicians, we can bring even the most complex and detailed designs to life. Whether it's elaborate geometric patterns or fine - detailed engravings, we deliver precision and quality every time.

- Consistency across large production runs: Our automated production systems, coupled with rigorous quality control measures, guarantee uniform quality throughout extensive manufacturing batches. Every part, regardless of the order size, adheres to the same high - standard specifications.

Production Process:

1. CAD file review and optimization

2. Material selection and preparation

3. Laser cutting

4. Quality inspection

5. Post-processing (if required)

6. Packaging and shipping

Applications:

Our Sheet Metal Fabrication Laser Cutting services cater to diverse industries, including:

- Automotive components

- Aerospace parts

- Electronic enclosures

- HVAC systems

- Signage and displays

- Industrial machinery

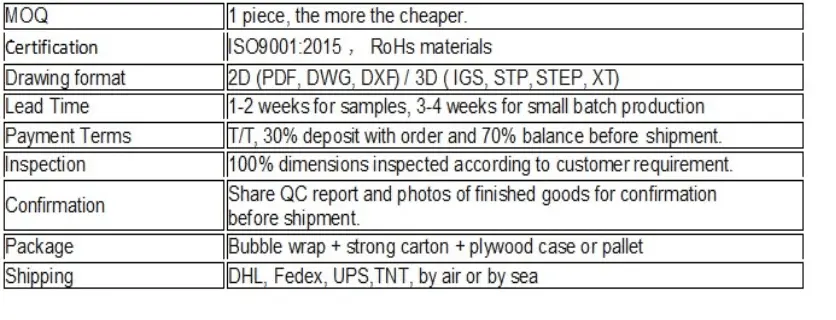

Delivery terms

FAQs

Q1: Will my drawing be safe after you get it?

A1: Yes, we pay much attention to protect our customers’ privacy of drawings and we can sign the NDA before

you send the drawings.

Q2: What is your way of packing?

A2: Normally we pack goods according to customers’ requirement. For reference: wrapping paper, carton

box, wooden case, pallet.

YOU MAY LIKE

_1744788508965.png)