Product Details

|

Product Name |

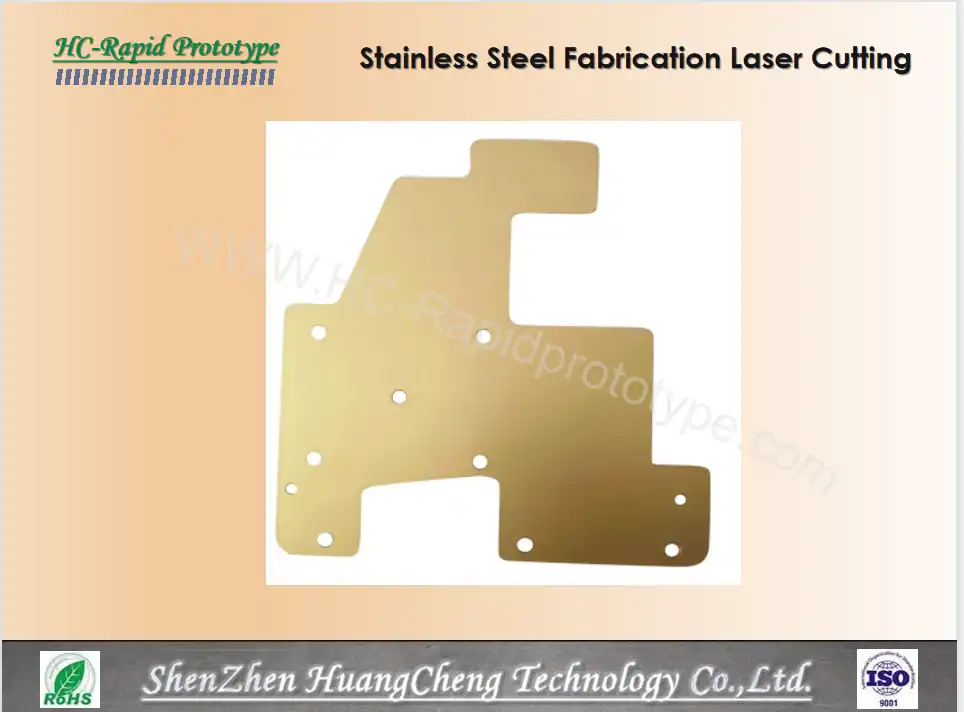

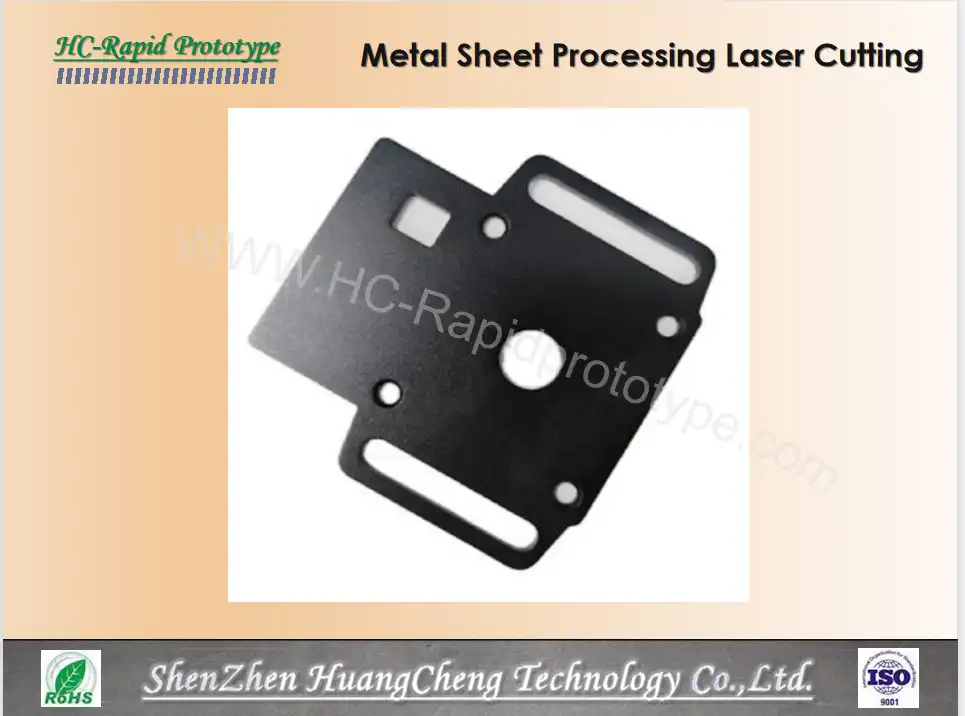

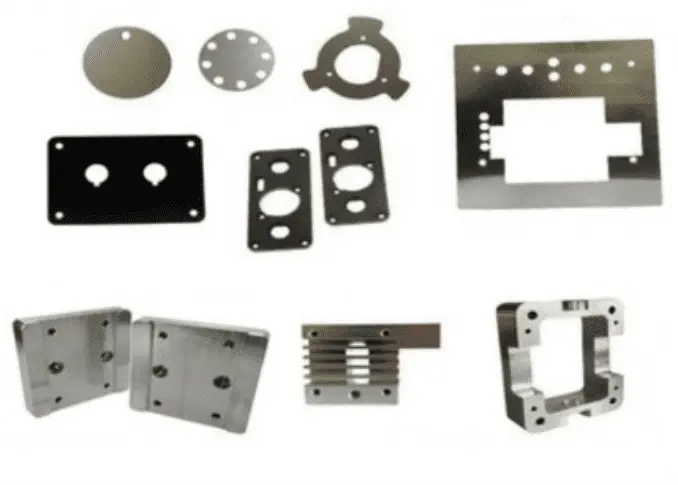

Anodizing Service with Laser Cutting |

|

Color |

According to customer request |

|

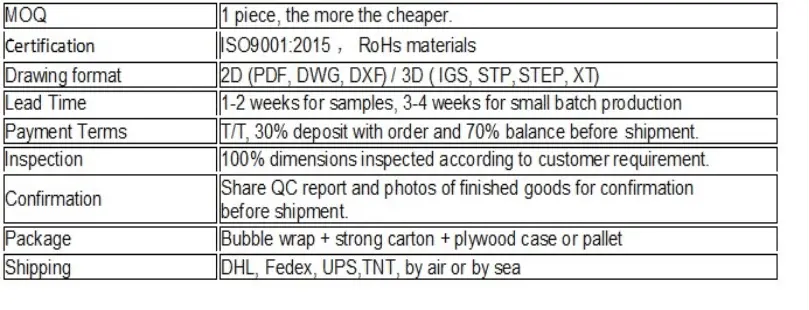

MOQ |

1 pc or more |

|

Raw Material |

Aluminum or aluminum alloy |

|

Micro Machining or Not |

Micro Machining |

|

Model Number |

Custom |

|

Surface Treatment |

Anodizing |

Introduction

Ordinary users may be unfamiliar with anodized aluminum laser marking, but in fact, the electronic 3C products used in our daily life, such as mobile phones, notebooks and other shells, use the laser process of this material.

Anodized aluminum, the full name is anodized aluminum, refers to a layer of dense aluminum oxide on the surface of aluminum or aluminum alloy to prevent oxidation of aluminum or aluminum alloy. Although the chemical properties of anodized aluminum are the same as those formed by natural oxidation, the corrosion resistance, wear resistance and decorative properties of anodized aluminum are superior to those formed by natural oxidation.

*More Anodizing Service with Laser Cutting parts for information

HC-Rapidprototype Advantage and Service:

- Rapid turnaround times: Leveraging advanced production scheduling software and streamlined workflows, we efficiently manage projects to ensure quick order fulfillment without sacrificing quality.

- Customized solutions for unique requirements: Our experienced team collaborates closely with clients, using in-depth industry knowledge to develop personalized solutions that perfectly match specific needs.

- Comprehensive quality control measures: From raw material inspection to final product testing, we implement multi - stage checks, using advanced equipment to ensure every item meets stringent quality standards.

- Expert consultation throughout the process: Seasoned professionals offer guidance at every stage, from initial design concepts to after - sales support, ensuring clients make informed decisions.

- Competitive pricing for bulk orders: By optimizing our supply chain, negotiating favorable terms with suppliers, and achieving economies of scale, we provide attractive pricing for large - volume purchases.

Product Characteristics:

- Enhanced corrosion and wear resistance: Employing advanced coating technologies like PVD and CVD, we apply durable protective layers that shield products from harsh environments, extending their lifespan significantly.

- Improved surface hardness: Through heat treatment processes such as quenching and tempering, combined with hardening techniques, we boost surface hardness, ensuring products withstand heavy usage and impacts.

- Decorative finish options: Our wide range of finishing techniques, including electroplating, anodizing, and powder coating, offers numerous aesthetic choices, allowing products to stand out while maintaining functionality.

- Precise, intricate designs possible through laser cutting: Harnessing high - power laser technology with micron - level precision, we can create detailed and complex patterns on various materials, meeting the most demanding design requirements.

- Excellent electrical insulation properties: Utilizing specialized insulating materials and advanced manufacturing processes, we ensure products provide reliable electrical isolation, safeguarding against short circuits and electrical failures.

Comment

Anodizing Service with Laser Cutting has the following process advantages:

- Fiber laser, high beam quality, small focusing spot, ultra-fine marking and high definition: Our fiber lasers boast superior beam quality, enabling a minuscule focusing spot that achieves ultra-fine marking with crystal-clear, high-definition results on diverse materials.

- Digital high-speed scanning galvanometer with high machining accuracy and stable performance: The digital high-speed scanning galvanometer ensures pinpoint machining accuracy and consistent operation, facilitating precise and efficient laser processing for various applications.

- Hardware setting and marking control are integrated, the marking speed is fast and the effect is better: With integrated hardware setting and marking control systems, our equipment offers rapid marking speeds while delivering enhanced, more professional marking effects.

Delivery

Please refer to below table to get the details of delivery terms

FAQs

Q1: What is your quality process?

A1: New drawings analysis - the internal production control conversion - drawing process

flow chart - first manufacturing inspection - modified with numerical optimization -

normal production - QC inspection record - surface treatment - FQC inspection report and record – packaging – logistics.

Q2. Do you measure details and attach measure protocol with delivery?

A2. Yes, inspection report, material certificate, packing list and material details of label

All are attached in the package.

YOU MAY LIKE

_1744788508965.png)