Product Details

|

Name |

High Precision Laser Cutting |

|

Size |

Customized dimensions |

|

MOQ |

1 piece |

|

Tolerance |

0.01-0.05mm |

|

Type |

Laser Cutting |

|

Service |

Customized OEM |

Introduction

Laser cutting is a non-contact, thermal-based manufacturing process that combines focused heat and thermal energy, applying pressure to melt and eject material at narrow paths or cuts. Unlike traditional cutting methods, laser cutting offers numerous significant advantages. The highly concentrated energy from the laser, coupled with CNC control, enables the precise cutting of materials with varying thicknesses and intricate shapes. This precision ensures that parts can be manufactured with extremely tight tolerances, meeting the most exacting standards in industries such as aerospace, electronics, and automotive. Moreover, the accuracy of laser cutting reduces material waste, optimizing resource utilization and lowering production costs. Additionally, its ability to process a diverse range of materials, including metals, plastics, and composites, makes it a versatile solution for a wide array of manufacturing needs.

Precision Laser Cutting Advantages

1. Excellent precision

2. Improve workplace safety

3. Greater material versatility

4. Faster delivery time

5. Lower material cost

Application

The High Precision Laser Cutting process has become an indispensable technology across a vast spectrum of manufacturing applications. In the automotive industry, it has emerged as a game - changer, enabling the production of intricate and robust components from diverse materials. Whether it's crafting hydroformed 3D shapes that enhance vehicle structural integrity or manufacturing parts for airbag systems that demand utmost precision for safety, laser cutting delivers consistent, high - quality results. In the precision electronics sector, this process is crucial for finishing metal or plastic parts, fabricating durable housings, and precisely cutting circuit boards to ensure seamless functionality. From small - scale machining workshops that benefit from its flexibility and efficiency to large industrial facilities that rely on its high - volume production capabilities, precision laser cutting offers manufacturers unparalleled advantages. It combines speed, accuracy, and the ability to work with a wide range of materials, making it an essential tool for modern manufacturing.

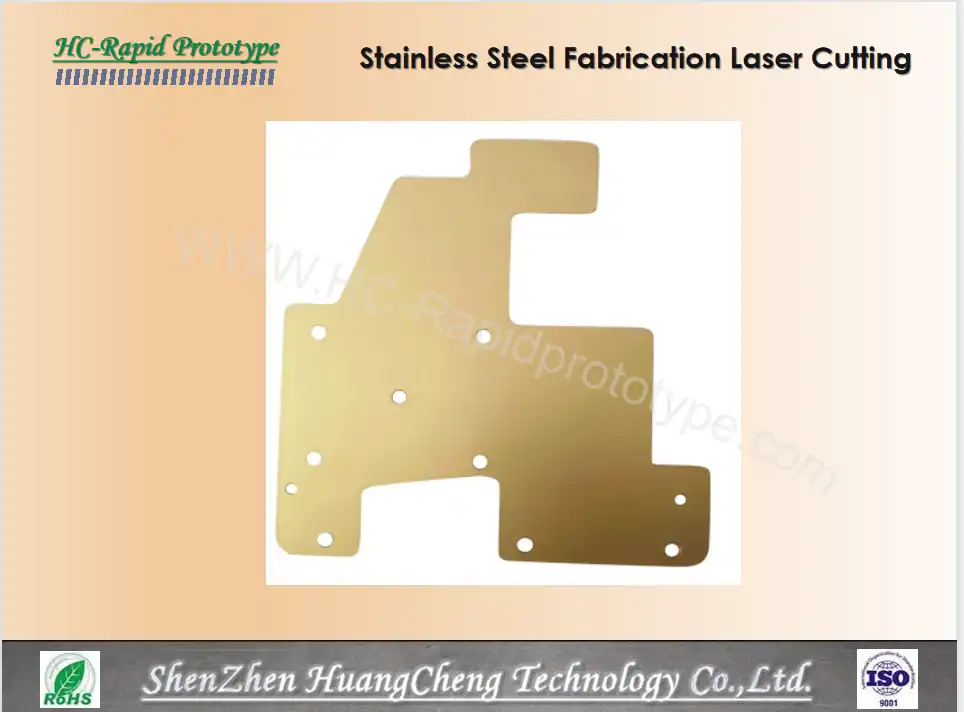

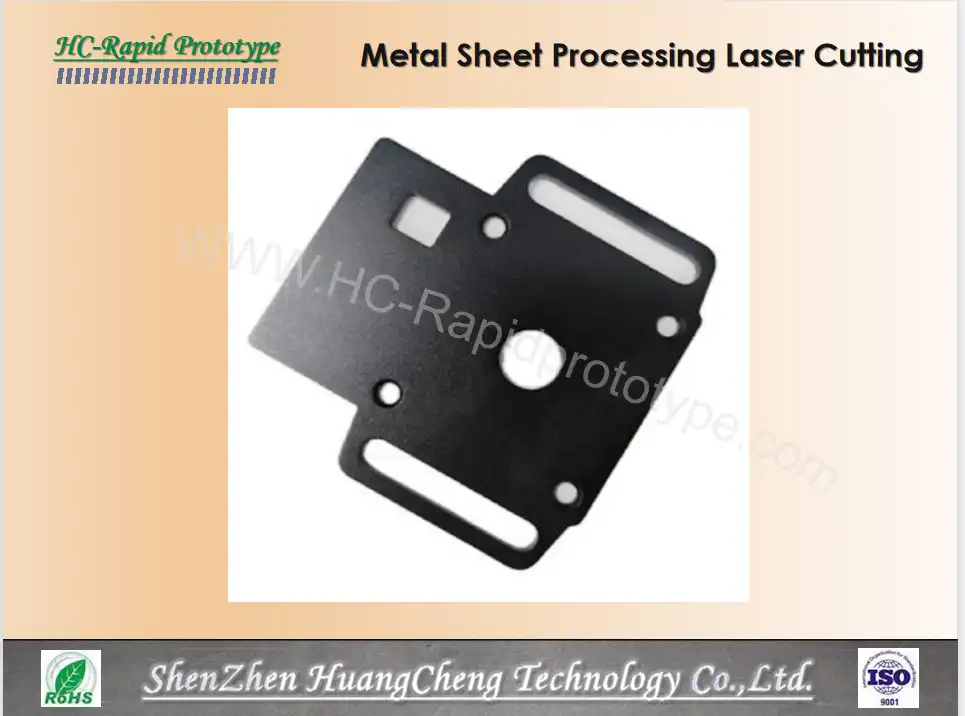

*More High Precision Laser Cutting part for reference

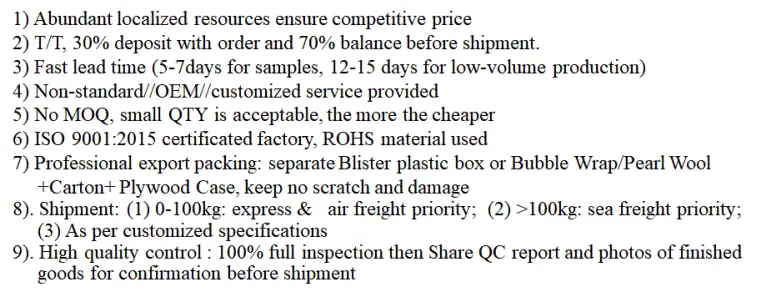

Delivery Info

Why Choose ShenZhenHuangCheng Technology Co., Ltd.?

- Cutting-edge technology for superior results: We employ the latest and most advanced manufacturing and processing technologies. These state-of-the-art tools and systems ensure that every project we undertake delivers outstanding, high - quality outcomes that exceed industry standards.

- Experienced team dedicated to your success: Our team consists of highly skilled professionals with years of hands - on experience. Committed to your goals, they work tirelessly to understand your needs and deliver solutions that drive your business forward.

- Competitive pricing without compromising on quality: Through efficient production processes and strong supplier relationships, we are able to offer cost - effective pricing. You can expect top - notch quality products and services at rates that are highly competitive in the market.

- Fast turnaround times to meet your deadlines: We recognize the importance of time in business. Our streamlined workflows and optimized operations allow us to complete projects promptly, ensuring that you receive your orders exactly when you need them.

- Comprehensive service from design optimization to final delivery: From the initial stage of optimizing your designs for manufacturability to the final delivery of the finished product, we provide end - to - end support, handling every aspect of the project with care and expertise.

FAQs

Q1: What's the basic information do you need for each quotation?

A2: Detailed 2D or 3D drawings (JPG, PDF, DWG, DXF, IGS, STP, STEP, XT) with material,

quantity and surface treatment information.

Q2: What is your way of packing?

A2: Normally we pack goods according to customers’ requirement. For reference: wrapping paper,

carton box, wooden case, pallet.

YOU MAY LIKE

_1744788508965.png)