Product Details

|

Name |

High Quality Laser Cutting |

|

Product Size |

Refer to customer requirement |

|

Surface Roughness |

Ra0.1 ~ 3.2 |

|

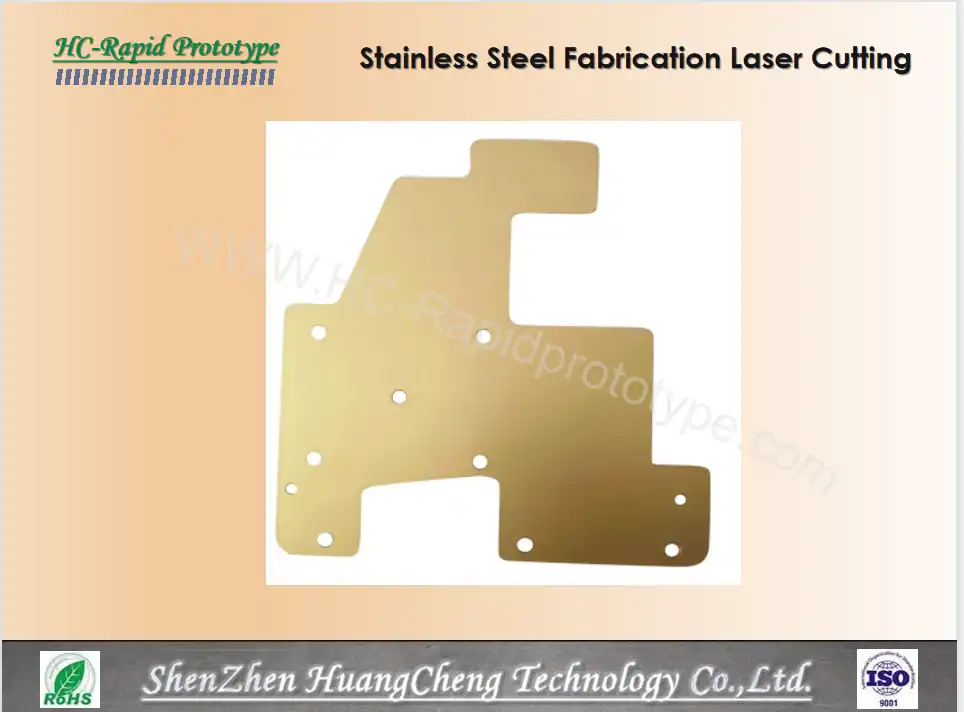

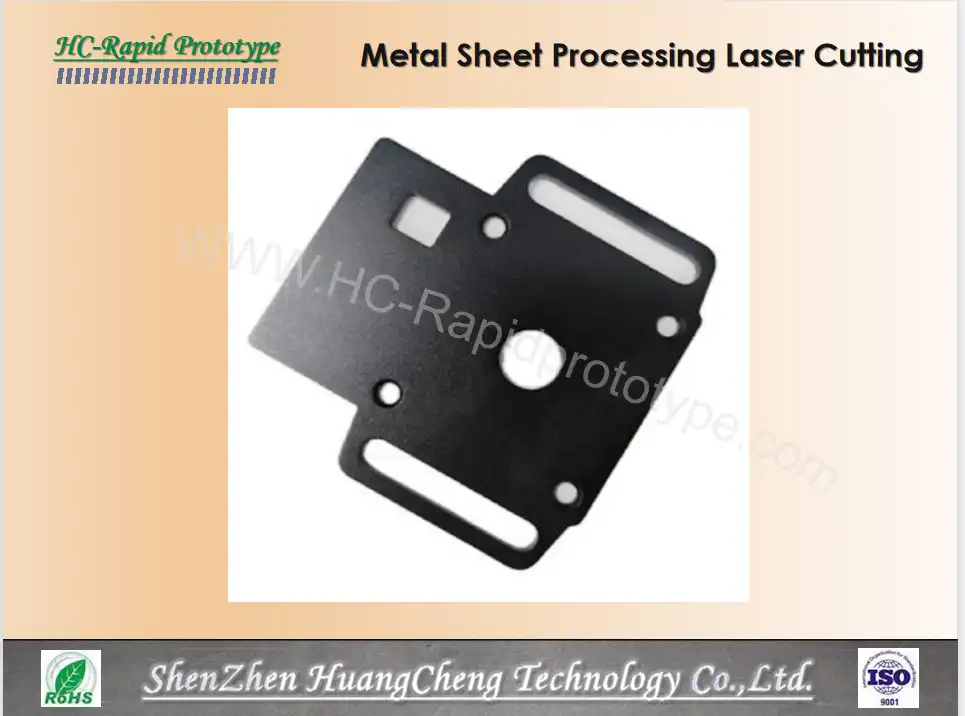

Raw Material |

Aluminum, Stainless Steel, Brass , Metals and others |

|

Surface Treatment |

Polishing, surface marking etc. |

|

Application |

Motorcycle, Machinery, Bicycles, Automotive, Medical devices etc. |

Introduction

High Quality Laser Cutting technology has the following advantages:

1. High precision: the positioning accuracy is 0.05mm, and the repeated positioning accuracy is 0.02mm.

2. The slit is narrow: the laser beam is focused into a very small spot, so that a high power density is achieved at the focus, and the material is heated to the degree of gasification and evaporates to form holes. As the beam moves linearly relative to the material, the holes are continuously formed into narrow slits. The width of the incision is generally 0.10-0.20mm.

3. The cutting surface is smooth: there is no burr on the cutting surface, and the surface roughness of the incision is generally controlled within Ra2.5mm.

4. Fast speed: the cutting speed can reach 10m/min, and the maximum positioning speed can reach 70m/min, which is much faster than wire cutting.

5. The cutting quality is good: non-contact cutting, the cutting edge is less affected by heat, there is basically no thermal deformation of the workpiece, and the slump formed when the material is punched and sheared is completely avoided, and the cutting seam generally does not require secondary processing.

6. No damage to the workpiece: the laser cutting head will not contact the surface of the material to ensure that the workpiece will not be scratched.

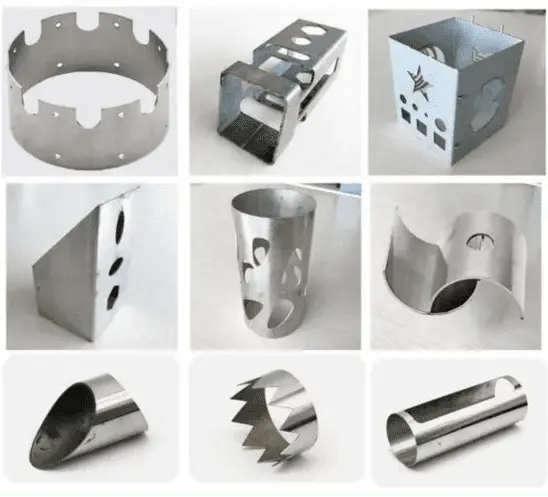

7. It is not affected by the hardness of the material to be cut: the laser can process steel plates, stainless steel, aluminum alloy plates, cemented carbide, etc., no matter what kind of hardness, it can be cut without deformation.

8. It is not affected by the shape of the workpiece: the laser processing is flexible, can process any graphics, and can cut pipes and other special-shaped materials.

9. Non-metals can be cut and processed: such as plastic, wood, PVC, leather, textiles and plexiglass.

10. Save mold investment: laser processing does not require molds, no mold consumption, no need to repair molds, saving mold replacement time, thereby saving processing costs and reducing production costs, especially suitable for the processing of large products.

11. Save materials: by using computer programming, products of different shapes can be cut out of the whole board material to maximize the utilization rate of materials.

12. Shorten the manufacturing cycle of new products: new products are trial-produced, the quantity is small, the structure is uncertain, and can be changed at any time. The laser cutting machine greatly shortens the manufacturing cycle of new products and reduces the investment in molds.

Product Characteristics:

- High-precision cutting for a wide range of materials

- Energy-efficient operation for reduced running costs

- User-friendly interface for easy operation and maintenance

- Advanced safety features to protect operators

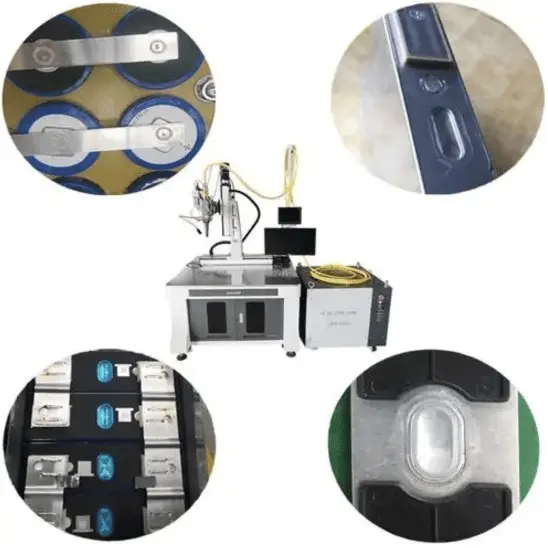

Production Process:

1. Material loading and positioning

2. CAD/CAM file input and optimization

3. Laser cutting execution

4. Quality control inspection

5. Finished product unloading

Applications:

- Automotive parts manufacturing

- Aerospace component production

- Electronics industry

- Metal fabrication

- Signage and display creation

High Quality Laser Cutting parts

Laser Cutting is suitable for a wide range of materials machining, not only metal but also plastic and other materials, it can manufacture a variety of custom-designed products. it is also good for manufacturing high accuracy parts in prototype.

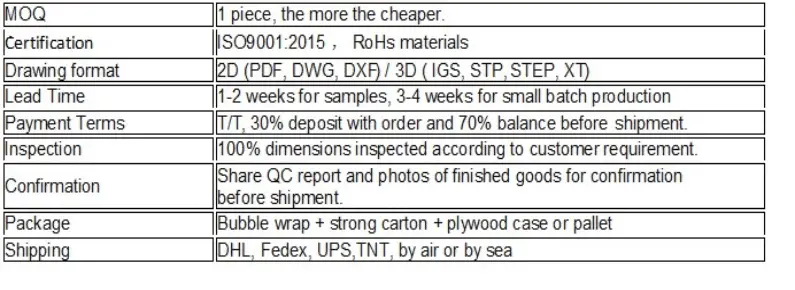

Delivery

The delivery terms for the finished goods please refer to below table

Why Choose ShenZhenHuangCheng Technology?

- Industry-leading expertise in laser cutting technology

- Commitment to innovation and continuous improvement

- Proven track record of reliability and performance

- Competitive pricing without compromising on quality

FAQs

Q:How do you guarantee the lead time?

A:-We will make achievable production arrangement before order.

-We will monitor production activity on daily basis.

-We will send production report on weekly basis.

Q: How does high quality laser cutting compare to traditional cutting methods?

A: Our laser cutting technology offers superior precision, faster processing speeds, and the ability to cut complex shapes that would be difficult or impossible with traditional methods.

Q: Can your laser cutting systems handle different materials?

A: Yes, our versatile systems can cut a wide range of materials including metals, plastics, wood, and composites with exceptional accuracy.

Q: What kind of support do you offer after purchase?

A: We provide comprehensive after-sales support, including installation, training, maintenance, and ongoing technical assistance to ensure your laser cutting system operates at peak performance.

YOU MAY LIKE

_1744788508965.png)