Product Details

|

Product Name |

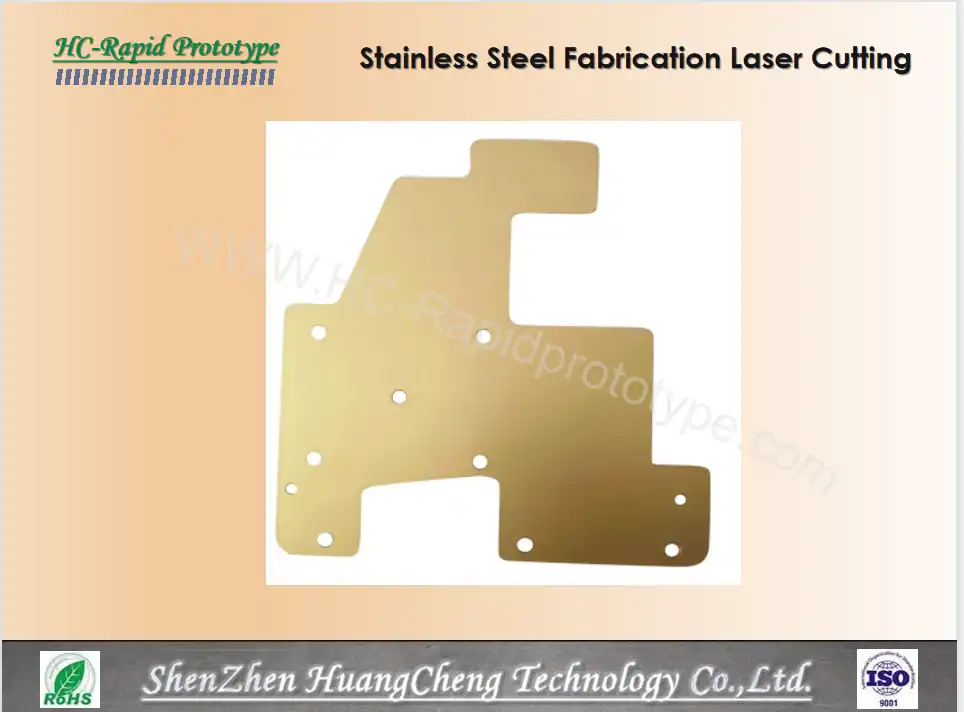

Stainless Steel Fabrication Laser Cutting |

|

Product Size |

Customized |

|

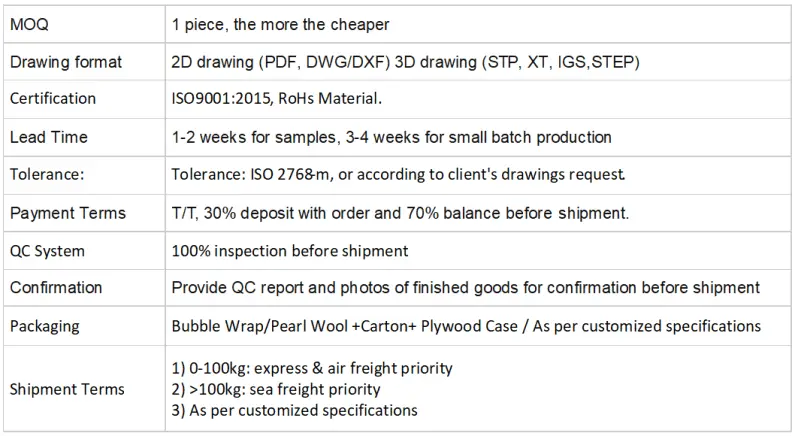

MOQ |

1 piece |

|

Raw Material |

Stainless Steel |

|

Surface Treatment |

Polishing and customized |

|

Application |

Machinery manufacturing, aerospace, auto parts and other industries. |

Introduction

The iron in the stainless steel will have an exothermic reaction with oxygen during cutting, and the oxidation of chromium has the property of preventing oxygen from entering the molten material, thereby reducing the amount of oxygen entering the molten layer. The oxidation of the molten layer is incomplete, the reaction is reduced, and the cutting speed drops. Compared with low carbon steel, stainless steel cutting requires higher laser power and oxygen pressure. Although Stainless Steel Fabrication Laser Cutting can achieve satisfactory cutting results, it is difficult to obtain a completely slag-free cutting seam. Using inert gas as auxiliary gas to cut stainless steel can obtain non-oxidative trimming, which is directly used for welding, but its cutting speed is about 10% lower than that of oxygen as auxiliary gas.

The most important process parameters that affect the cutting quality of stainless steel are cutting speed, laser power, oxygen pressure and focus, which respectively represent the influence of laser power, cutting speed and oxygen pressure on the cutting quality of stainless steel with a thickness of 2 mm.

HC-Rapidprototype Advantage and Service:

- Rapid turnaround times: We prioritize speed without sacrificing quality. Our streamlined operations and efficient workflows ensure that your orders are completed promptly, meeting even the tightest deadlines.

- Bulk order capabilities: Equipped with advanced production facilities and a skilled workforce, we can handle large - scale bulk orders with ease, ensuring consistent quality across high - volume production runs.

- Customization options: We understand that one size doesn't fit all. Our extensive customization options allow you to tailor products to your exact specifications, ensuring they perfectly meet your unique requirements.

- Competitive pricing for large - scale projects: Leveraging economies of scale and efficient production processes, we offer highly competitive pricing for large - scale projects, helping you maximize your budget without compromising on quality.

- Comprehensive quality control measures: From raw material inspection to final product testing, our multi - tiered quality control system rigorously monitors every stage of production, guaranteeing products of the highest standard.

Product Characteristics:

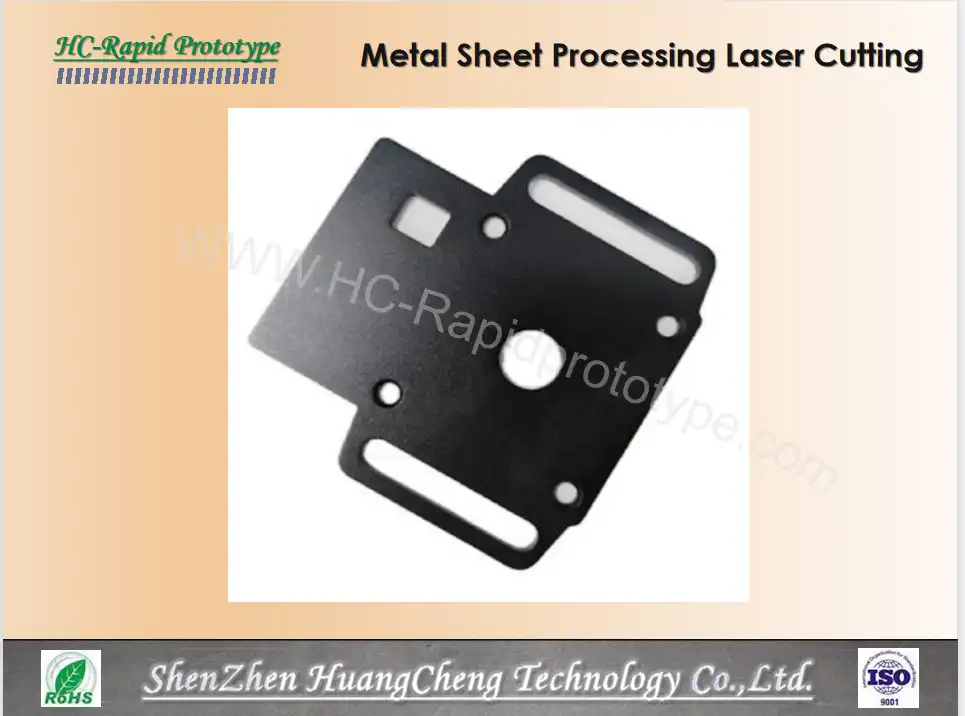

- High dimensional accuracy: Our advanced manufacturing technologies and precise measurement tools ensure that each part meets exact specifications, enabling seamless integration in complex assemblies with tight tolerance requirements.

- Excellent edge quality: Through state - of - the - art finishing processes, we achieve smooth, burr - free edges that not only enhance the aesthetic appeal but also improve the functionality and safety of the products.

- Minimal material waste: By utilizing optimized nesting algorithms and efficient cutting strategies, we maximize the utilization of raw materials, reducing waste and contributing to cost - effective and sustainable production.

- Consistent results across large production runs: Rigorous quality control protocols and automated production systems guarantee uniform quality throughout extensive manufacturing batches, ensuring reliability in every product.

- Suitable for complex geometries: With our sophisticated equipment and skilled craftsmanship, we can effortlessly fabricate parts with intricate shapes and contours, bringing even the most elaborate designs to life with precision.

Production Process:

1. CAD file optimization

2. Material selection and preparation

3. CNC laser cutting

4. Quality inspection

5. Post-processing (if required)

6. Packaging and shipping

Applications:

- Automotive components

- Aerospace parts

- Industrial machinery

- Construction elements

- Customized metal fabrication projects

Comment

1. Offer high-quality, high-precision products.

2. Various surface treatment options.

3. No worries after sale, we will solve any problem with Stainless Steel Fabrication Laser Cutting.

4. Rich rapid prototyping experience.

Delivery terms

FAQs

Q1: Do you accept the OEM sample and small production?

A1: Welcome! the sample can help you verify your design and our quality!

Q2: How do you make sure the price competitive based on the same quality?

A2: 1. Own factory assembly lines

2. Firsthand raw material sourcing

3. More than 10-year manufacturing experience

YOU MAY LIKE

_1744788508965.png)