Product Details

Product Name: High Demand Processing Laser Cutting

Micro Machining or Not: Micro Machining

Model Number: Custom

Size: Customized Size

Equipment: CNC Machining Centre

Lead Time:Rapid Prototypes:3-10 working days, Low-volume production:3-5 weeks

Introduction

With a solid foundation of over 10 years in the field of rapid prototyping, we have established ourselves as a trusted and experienced provider. Our prototyping concepts are firmly rooted in high precision, high quality, and high efficiency. These principles guide every aspect of our work, from the initial design stage to the final production of the prototype. When it comes to processing high - demand laser cutting parts, we spare no effort in ensuring excellence. Our team of skilled technicians utilizes state - of - the - art laser cutting equipment, which allows us to achieve intricate and accurate cuts with remarkable precision. After the parts are fabricated, all finished goods undergo a rigorous inspection process. We meticulously compare each part to the detailed requirements specified on the drawing, leaving no room for error. This thorough quality control measure guarantees that our laser - cut parts not only meet but exceed the expectations of our clients, making us the ideal choice for those seeking top - notch rapid prototyping services.

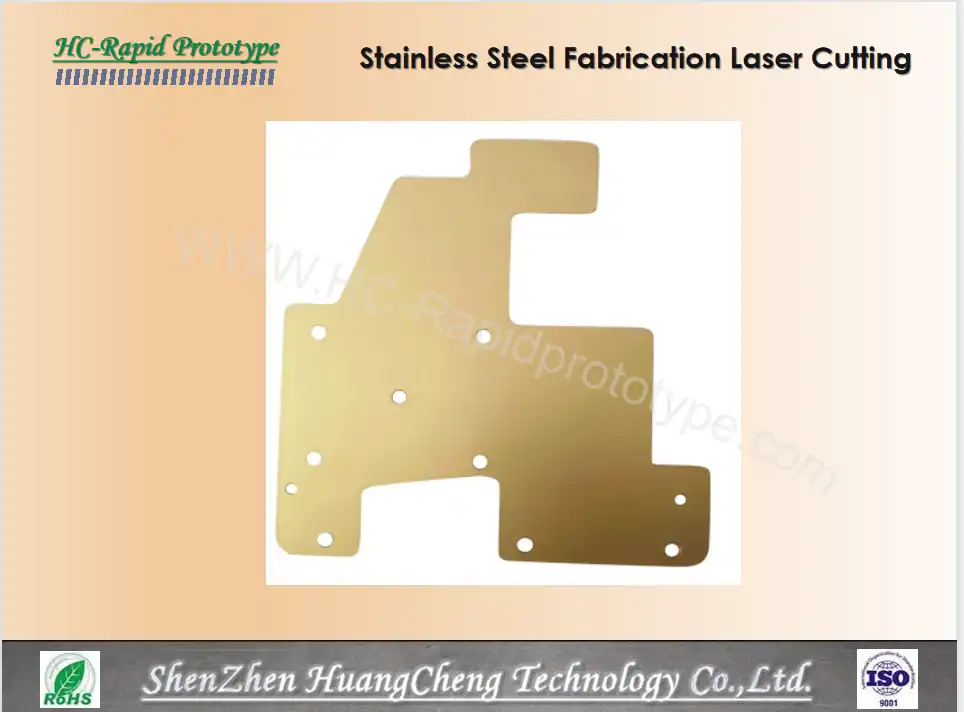

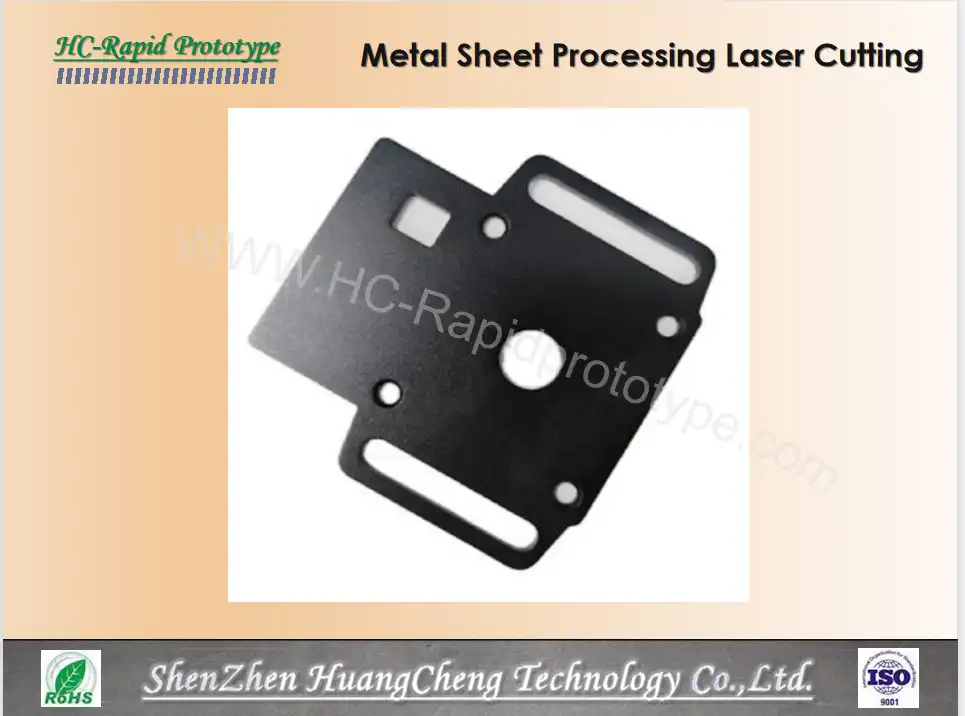

* High Demand Processing Laser Cutting Part for reference

Production Process

Our product equipment employs a sophisticated process:

- Material Loading: Automated systems precisely position your workpiece. These systems use advanced sensors and robotic arms to accurately place materials, ensuring they are correctly aligned for the cutting process and reducing manual errors.

- Cutting Path Generation: Advanced software optimizes cutting paths for efficiency. By analyzing the design and material properties, it calculates the most effective routes, minimizing cutting time and maximizing material utilization to save both time and cost.

- Laser Focusing: High-powered lasers are precisely focused for optimal cutting performance. Specialized lenses and focusing mechanisms fine-tune the laser beam, ensuring it delivers the right amount of energy to achieve clean, accurate cuts on various materials.

- Continuous Monitoring: Real-time adjustments ensure consistent quality throughout the process. Sensors constantly track parameters like laser power, cutting speed, and temperature, and any deviations are immediately corrected to maintain high - quality results.

- Finished Part Removal: Automated systems carefully extract completed parts. Using gentle yet secure gripping mechanisms, they safely remove the cut pieces without causing damage, preparing them for further processing or packaging.

Applications

Our High Demand Processing Laser Cutting solutions find applications across numerous industries:

- Automotive: In the automotive industry, precision cutting of body panels and intricate components is crucial. Advanced techniques ensure aerodynamic designs, structural integrity, and seamless assembly for enhanced vehicle performance and safety.

- Aerospace: For aerospace applications, the fabrication of lightweight yet strong structural elements is essential. Specialized processes create parts that can withstand extreme conditions while reducing aircraft weight for fuel efficiency.

- Electronics: In electronics, creating precise openings and contours in PCBs and enclosures demands high accuracy. This allows for proper component placement, effective heat dissipation, and reliable protection of internal circuitry.

- Metal Fabrication: Within metal fabrication, rapid prototyping and production of complex metal parts enable quick design iterations. This helps bring innovative products to market faster while maintaining high - quality standards.

Advantages

1. Various surface treatment

Plating , polish, heat treatment, Nickel, zinc, tin, silver, chrome plating , can meet your unique demand.

2. High Quality & Low Price

We have ISO9001 international quality management system, as well as Chinese production cost control experience , Our engineers can combine multiple processes to reduce costing with their rich experience, so the price of our products is lower.

3. Wide range of processing

We can manufacture aluminum, stainless steel , brass, copper, bronze, iron etc. parts and no matter how complex the shape is , we can do it well.

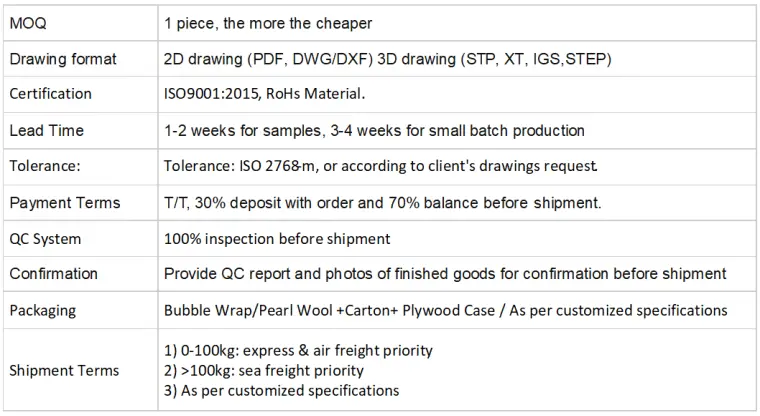

Delivery

FAQs

Q1: How can I get a quote?

A1: Detailed drawings with material, quantity and surface treatment information.

Q2: Is it possible to know how are my products going on without visiting your company?

A2: We will offer a detailed production schedule and send weekly reports with digital pictures or videos

which show the machining progress.

YOU MAY LIKE

_1744788508965.png)