Product Details

|

Product Name |

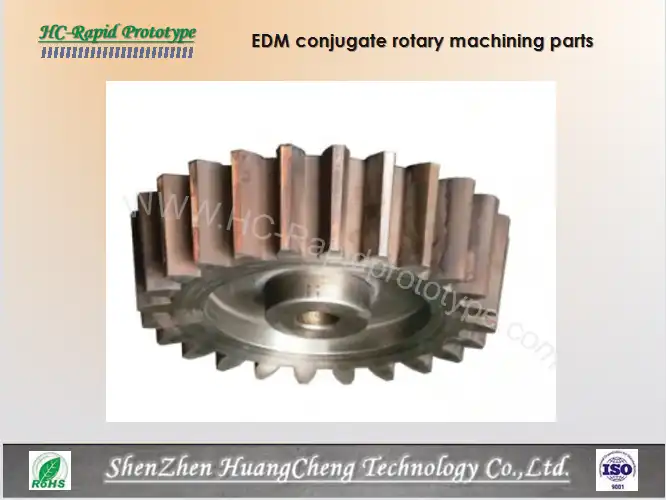

Electric spark machining Parts |

|

Product Size |

Customized Size |

|

MOQ |

1 piece |

|

Material |

Conductive material |

|

Surface Treatment |

Painting,Electroplating,Coating, Polishing,Anodizing |

|

Application |

Machinery manufacturing, aerospace, auto parts, Industrial Equipment |

Introduction

Sinker EDM Part offers unique advantages in the manufacturing realm. It is capable of processing materials and workpieces with complex shapes that pose significant challenges for conventional cutting methods. The absence of cutting force during the EDM process minimizes the risk of workpiece deformation, ensuring high - precision results. Additionally, it produces surfaces free from common defects like burrs, tool marks, and grooves, eliminating the need for extensive post - processing. Unlike traditional machining, the tool electrode material in EDM does not have to be harder than the workpiece material, providing flexibility in material selection. The process is also highly conducive to automation, enhancing production efficiency. However, it should be noted that a metamorphic layer forms on the surface after processing, which may require additional removal steps depending on the application. EDM finds extensive use in various industries. It is predominantly employed for machining molds and parts featuring complex hole and cavity geometries. It also excels in processing hard and brittle materials such as cemented carbide and hardened steel, which are otherwise difficult to machine. Moreover, EDM is ideal for tasks like machining deep and fine holes, special - shaped holes, deep grooves, slotting, and cutting thin slices. It is also widely used in the production of tools and measuring instruments, including various forming tools, templates, and thread ring gauges, ensuring high - quality and precise manufacturing.

HC-Rapidprototype Advantage:

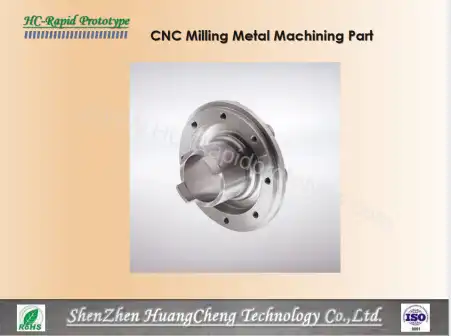

- State - of - the - art CNC machining centers and wire cutting machines empower us to achieve unparalleled precision and efficiency. These advanced machines can handle complex tasks, ensuring high - quality production of parts with intricate designs.

- Rigorous quality control throughout production guarantees that every product meets the highest standards. Multiple inspection points and strict testing procedures are in place to catch any flaws and ensure consistent, reliable output.

- Rapid prototyping capabilities for custom designs allow us to quickly turn your ideas into physical models. Using the latest technologies, we can produce prototypes in a short time, enabling faster design validation and iteration.

- Competitive pricing without sacrificing quality is our promise. Through optimized production processes and smart sourcing, we offer cost - effective solutions while maintaining top - notch quality in all our products.

Applications:

- Mold and die manufacturing is our specialty, where we craft high - quality tools using advanced techniques. Our molds and dies ensure consistent, precise production of various parts across multiple industries.

- We produce precision parts for the aerospace and automotive industries, meeting strict quality and performance standards. These parts are crucial for the reliability and efficiency of vehicles and aircraft.

- For the medical device sector, we create intricate components with utmost precision. These parts require high - quality materials and meticulous craftsmanship to ensure safety and functionality.

- Custom electrodes for unique Sinker EDM Part applications are designed and fabricated to your specific needs. Our electrodes are tailored to optimize performance and deliver accurate results in specialized machining tasks.

EDM characteristics

Sinker EDM Part has the following characteristics:

1. The energy density of pulse discharge is high, which is convenient for processing special materials and workpieces with complex shapes that are difficult or impossible to process with ordinary machining methods. Not affected by material hardness, not affected by heat treatment conditions.

2. The duration of pulse discharge is extremely short, the heat conduction and diffusion range generated during discharge is small, and the material affected by heat is small.

3. During processing, the tool electrode does not contact the workpiece material, and the macroscopic force between the two is extremely small. The tool electrode material does not need to be harder than the workpiece material, so the tool electrode is easy to manufacture.

4. It can reform the structure of workpiece, simplify the processing technology, improve the service life of workpiece, and reduce the labor intensity of workers

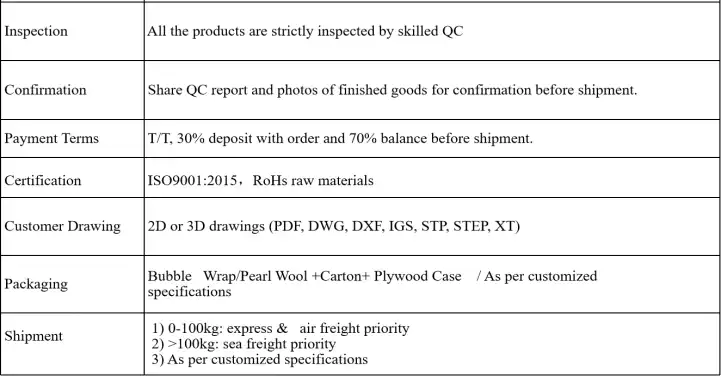

Delivery terms

FAQ

Q1: Do you make customized products based on our design drawings?

A1: Yes. Nearly all our products are customized. We are a professional metal fabrication factory with

an experienced engineering team to make custom products according to clients' drawings.

Q2: What is the MOQ?

A2: Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype

for clients to ensure quality standards.

YOU MAY LIKE

_1744788508965.png)