Product Details

|

Product Name |

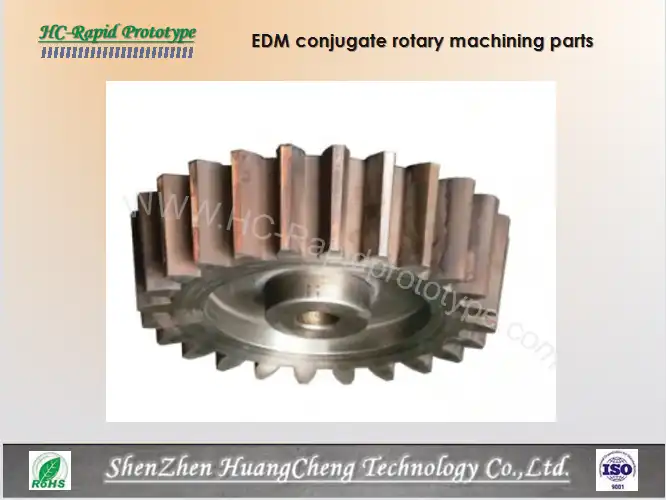

Electric spark surface strengthening parts |

|

Size |

Customer requirement |

|

Processing Method |

EDM machining |

|

Material |

Conductive raw material |

|

Finishing |

Defined by customer |

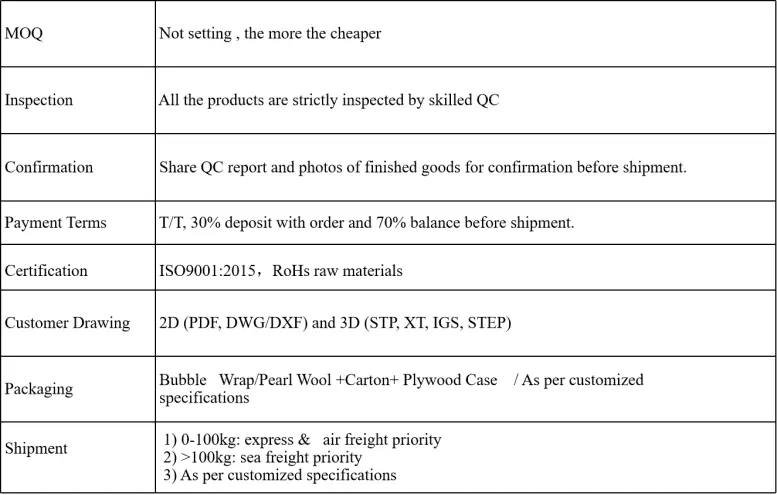

Delivery terms

Introduction

The surface strengthening process of EDM, or Electric spark surface strengthening parts, is a specialized technique that employs conductive materials such as hard alloy, graphite, alloy steel, aluminum, or steel as the working electrode within a pulse circuit. Operating in either air or a special gas medium, this process harnesses the power of electric spark discharge occurring between the workpiece and the working electrode. Through this unique mechanism, material from the working plate is effectively transferred onto the surface of the workpiece. This transfer of material leads to significant enhancements in the workpiece's properties. EDM surface strengthening is highly effective in improving the surface hardness, which makes the workpiece more resistant to external forces and abrasion. It also boosts wear resistance, ensuring the workpiece maintains its integrity over extended usage. Additionally, it enhances corrosion resistance, protecting the workpiece from chemical damage, and red hardness, allowing it to retain its strength even at elevated temperatures. Due to these remarkable benefits, EDM surface strengthening is widely applicable for the surface strengthening treatment of a diverse range of tools and molds, as well as fragile and easily corroded workpieces, making it an invaluable process in various manufacturing and engineering fields.

Advantage

- The equipment required for this process features a deceptively simple yet highly efficient design, which remarkably cuts down on the initial investment cost. Its uncomplicated structure not only simplifies maintenance procedures but also eases the operation process, even for those with limited technical expertise. This combination of low cost and user - friendliness enhances cost - effectiveness and makes it accessible for a wide range of users across different industries.

- The infiltration layer establishes an incredibly robust and enduring connection with the substrate, ensuring sustained long - term stability under various circumstances. This tenacious bond resists peeling even when subjected to arduous operating conditions, extreme temperatures, or significant mechanical stress. As a result, it effectively safeguards the integrity of the treated material, prolonging its lifespan and performance.

- During the process, the consumption of electrode materials is extremely low, setting it apart from many traditional methods. This low usage rate offers the flexibility and freedom to select electrode materials according to specific application needs, whether it's for enhanced conductivity, durability, or other performance - related factors. By doing so, it optimizes performance while simultaneously minimizing material waste and reducing overall costs.

- Localized heating employed in this process is a key feature that keeps power consumption at an absolute minimum. Unlike processes that require extensive heating of the entire workpiece, this targeted approach saves energy. Furthermore, it is not limited by the size of the parts being processed, allowing for equally efficient treatment of both small - scale components and large - scale industrial parts, all while delivering consistent results.

- High - energy density heating in this process selectively modifies only the surface of the material, leaving the internal structure and performance completely intact. This precision - based approach ensures that parts retain their shape post - treatment, eliminating the risk of deformation. As a result, it guarantees precise dimensional accuracy and reliable quality, making it suitable for applications where high precision is critical.

Application

Application of EDM Surface Strengthening Technology

In the realm of electromechanical equipment repair, Electric spark surface strengthening part plays a crucial role. It is primarily employed for roughing operations, strengthening, and restoring the worn surfaces of parts that have undergone hard alloy surfacing. Additionally, EDM proves highly effective in removing broken drill bits, dies, bolts, and creating drill grooves within holes of any shape. Impressively, the EDM repair layer can reach a thickness of up to 0.5 mm. The choice of anode material varies based on the repair task. For instance, when fixing the bearing seat hole on a cast iron housing, copper is used as the anode material. When strengthening a worn journal of a part, cutting tools made from materials like ferrochrome, graphite, and T15K6 cemented carbide serve as the anode, ensuring efficient repair and strengthening.

Remark

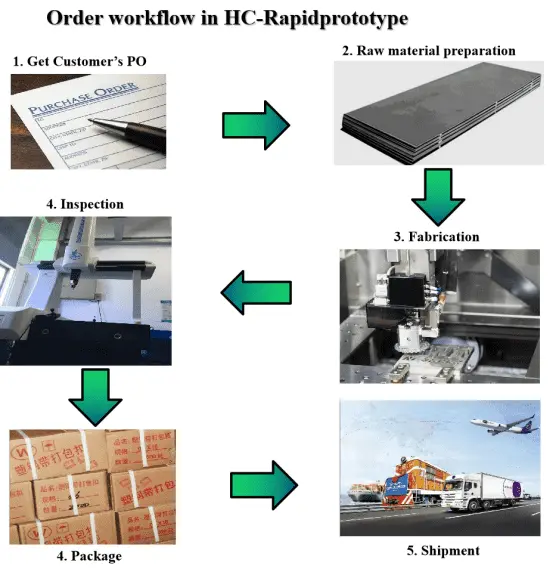

How you products are going on our company? Please refer to below picture for details

YOU MAY LIKE

_1744788508965.png)