Product Details

|

Product Name |

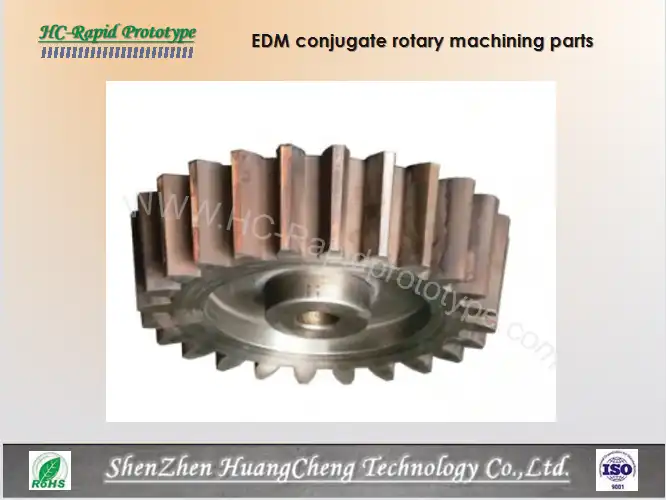

Electric-spark grinding Parts |

|

Size |

Customized |

|

Accuracy |

0.005 mm |

|

Roughness |

Rα1.25~0.16 µm |

|

Material |

Metals, steel, aluminum and others |

|

Finishing |

Painting, Electroplating, Coating, Polishing, Anodizing etc. |

Application

EDM grinding stands out as a highly versatile and efficient machining method, suitable for processing any conductive material. It truly shines when dealing with hard materials that pose significant challenges to traditional mechanical grinding techniques. For instance, it excels in grinding carbide forming tools, which require extreme precision due to their complex shapes and high hardness. The inserts of indexable tools, hardened insert molds, and racks also benefit greatly from EDM grinding, as it can achieve the fine tolerances necessary for their proper functioning. One of the most remarkable aspects of EDM grinding is the absence of mechanical cutting force during the process. This unique feature allows it to handle delicate tasks with ease. It can be used to grind fine, thin - walled parts that are prone to deformation under mechanical stress, ensuring their structural integrity remains intact. Additionally, it is perfectly suited for creating deep grooves and slits, where the lack of mechanical force prevents unwanted damage and guarantees high - quality results.

Introduction

Electric-spark grinding Parts offers a highly adaptable and efficient solution for machining a wide range of conductive materials. Its real strength lies in its ability to handle hard materials that are extremely challenging to process using traditional mechanical grinding methods. Materials such as carbide, which are commonly used in forming tools, possess high hardness and brittleness, making them difficult to shape with conventional techniques. However, electric - spark grinding can precisely grind carbide forming tools, as well as the inserts of indexable tools, hardened insert molds, and racks. The absence of mechanical cutting force during the electric - spark grinding process is a game - changer. This unique characteristic allows it to work on fine, thin - walled parts that are highly susceptible to deformation under mechanical stress. For example, in the production of micro - components or parts with intricate geometries, traditional grinding could cause distortion, but electric - spark grinding ensures the integrity of these delicate structures. Moreover, it is ideal for creating deep grooves and slits with high precision, further expanding its application scope in various manufacturing industries where complex and precise machining is required.

HC-Rapidprototype Advantage and Service:

- Rapid prototyping and production capabilities enable us to swiftly transform ideas into tangible products. Using advanced technologies, we can quickly produce prototypes for testing and full - scale production runs to meet market demands promptly.

- Customization options to meet specific requirements allow us to tailor our products precisely to your needs. Our team collaborates closely with you to ensure every detail aligns with your unique specifications and preferences.

- Expert technical support throughout the project lifecycle means our experienced professionals are always available. From initial planning to final delivery, we offer guidance, troubleshoot issues, and ensure a smooth project execution.

- Competitive pricing without compromising on quality is our commitment. Through efficient processes and smart sourcing, we provide cost - effective solutions while maintaining the highest standards of product excellence.

- Quick turnaround times and on - time delivery ensure your projects stay on schedule. Our streamlined operations and dedicated logistics team work together to get your products to you as fast as possible.

EDM characteristics

Electric-spark grinding Parts has the following characteristics: it can process any conductive materials with high strength, high hardness, high toughness, high brittleness and high purity; there is no obvious mechanical force during processing, and it is suitable for processing low-rigidity workpieces and microstructures: pulse parameters can be based on Need to adjust, roughing, semi-finishing and finishing can be performed on the same machine tool; the pits on the surface after EDM are conducive to oil storage and noise reduction; the production efficiency is lower than that of cutting; the discharge process is partially Energy is dissipated on the tool electrode, which leads to electrode wear and affects the forming accuracy.

Shipment

Why Choose XCMOTOR?

- Decades of experience in EDM and precision machining have equipped us with in - depth knowledge and expertise. We leverage our long - standing know - how to tackle complex projects, delivering high - quality results with unparalleled consistency.

- Continuous investment in cutting - edge technology keeps us at the forefront of the industry. This enables us to offer advanced machining solutions, ensuring enhanced precision, efficiency, and the ability to handle the most challenging requirements.

- Rigorous quality control processes are integrated into every stage of production. From raw material inspection to final product testing, multiple checks are carried out to guarantee that all items meet or exceed strict industry standards.

- Flexible production capabilities allow us to seamlessly adapt to varying order volumes. Whether it's a small - batch custom job or a large - scale production run, we can efficiently allocate resources to meet your specific needs on time.

- Comprehensive support from design to delivery means our team is with you every step of the way. We provide expert advice during the design phase, oversee production, and ensure smooth delivery, offering a hassle - free experience.

FAQs

Q1: What's the basic information do you need for each quotation?

A1: Detailed 2D or 3D drawings (JPG, PDF, DWG, DXF, IGS, STP, STEP, XT) with material, quantity and surface

treatment information.

Q2: How you guarantee the quality?

A2: Our prototype will be strictly complied with the requirements on drawing. We offer details photos and QC report to let you confirm before shipment.

YOU MAY LIKE

_1744788508965.png)