Product Details

|

Product Name |

POM-like vacuum casting parts |

|

Product Size |

Customized Size |

|

MOQ |

1 piece |

|

Lead Time |

3-7working days for samples, 1-2 weeks for small batch production |

|

Processing Method |

Plastic Vacuum casting |

|

Raw Material |

PEL - URETHANE XU-50A/XU-50B |

|

Finishing |

Polishing, silk screen etc. |

|

Customer Drawing |

DWG,PDF,DXF/STP,STEP,IGS,XT etc. |

Why Choose ShenZhenHuangCheng Technology Co.,Ltd?

- Our expertise in the products is deeply rooted in years of research and development. Our team of specialists thoroughly understands every aspect, enabling us to offer innovative solutions and high - quality results.

- Advanced manufacturing facilities equipped with the latest technology ensure precision and efficiency. These state - of - the - art tools and machinery allow us to produce products that meet the highest industry standards.

- Rigorous quality control measures are implemented at every stage of production. From raw material inspection to final product testing, we ensure that only flawless items are delivered to our customers.

- Flexible production capabilities mean we can handle orders of all sizes, from small - batch prototypes to large - scale production runs. We adapt to your needs and deliver products in a timely manner.

- Competitive pricing is achieved through optimized processes and strategic sourcing. We provide cost - effective solutions without sacrificing the quality and performance of our products.

- Excellent customer service and support are our top priorities. Our dedicated team is always ready to assist, answering your questions promptly and providing solutions throughout your experience with us.

POM-like Properties

◎ Appearance similar to POM resin

◎ Fast curing polyurethane resin

◎ 150℃ ultra-high heat resistance, 87D high hardness, 0.2% extremely low shrinkage

|

Project |

Conditions ・ Unit |

XU-50A |

XU-50B |

|

Appearance |

Standards |

Light grey/black |

Light yellow/transparent |

|

Specific weight |

25℃ |

1.16 |

1.19 |

|

Viscosity |

25℃ mPa・s |

800 |

170 |

Introduction

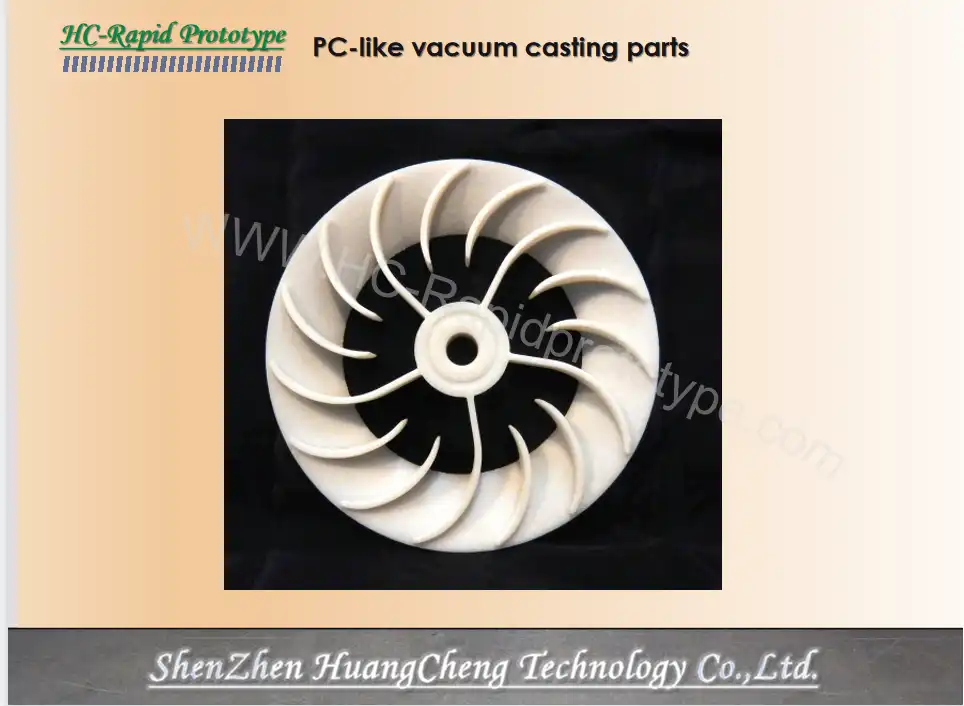

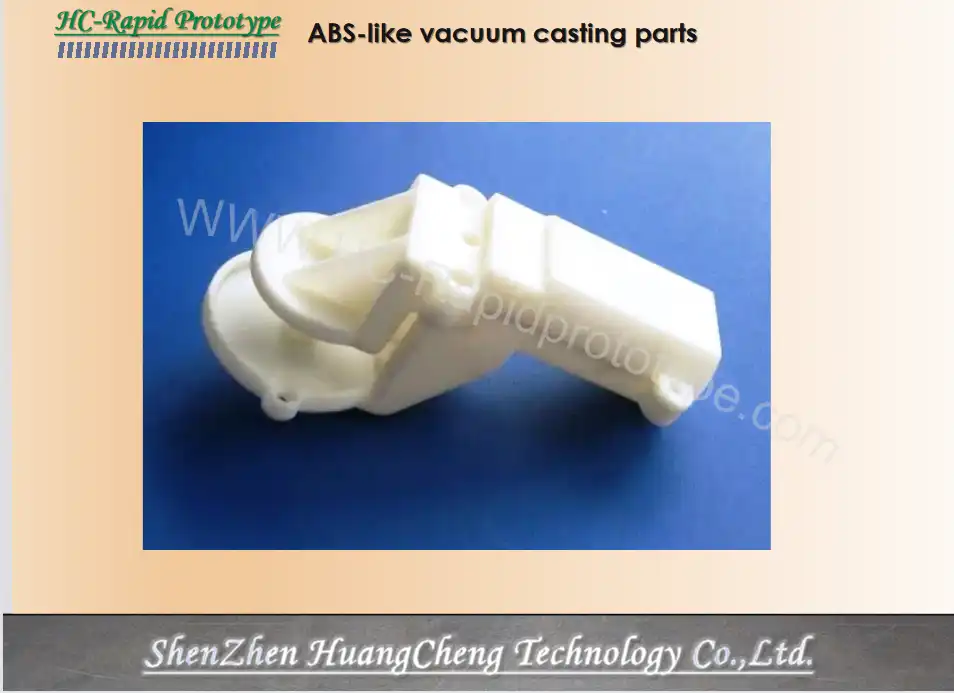

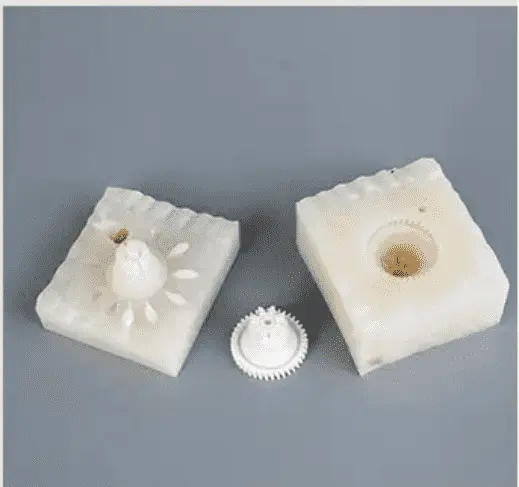

POM-like vacuum casting parts are mainly used for rapid prototyping vacuum casting prototypes of gears, bearings, auto parts, machine tools, instrument internals, toys etc. The prototypes have following characteristics:

- This material showcases remarkable comprehensive performance and colorability. With a high elastic modulus, it offers substantial rigidity and hardness. Its specific strength and specific rigidity are impressively close to those of metal, making it a top - tier choice for diverse applications.

- It exhibits outstanding tensile strength, bending strength, along with excellent creep and fatigue resistance. Capable of withstanding repeated impacts, it also demonstrates remarkable recovery from applied loads, ensuring long - term durability and reliability.

- Featuring a low friction coefficient, it is highly wear - resistant and maintains excellent dimensional stability. It has a good surface gloss, high viscoelasticity, and superior electrical insulation that remains unaffected by temperature changes. Its insulation resistance also stays consistent regardless of humidity.

- Boasting excellent chemical resistance, this material can endure exposure to a wide range of chemicals without degradation. It resists corrosion and chemical reactions, ensuring its integrity in harsh chemical environments.

Advantages

Vacuum casting prototypes have following advantages.

- The low cost of silicone mold is a significant advantage. Unlike traditional hard - tooling methods, silicone mold production requires less complex equipment and labor, reducing both material and manufacturing costs, making it budget - friendly for various projects.

- Fast delivery is a key feature of silicone mold manufacturing. The streamlined process, from mold creation to part production, allows for quick turnaround times. This enables clients to receive their products promptly, accelerating the development and launch of new items.

- A wide selection of materials for silicone molds offers great flexibility. Whether it's high - temperature resistant, food - grade, or highly flexible silicone, there are options to suit different application requirements, ensuring optimal performance for each project.

- High precision and fine details are hallmarks of silicone molds. Advanced techniques and the flexibility of silicone material ensure that even the most intricate designs and tiny features are accurately replicated, meeting strict quality standards.

- An excellent surface finish is consistently achieved with silicone molds. The smooth and flawless texture of parts produced eliminates the need for extensive post - processing, saving time and enhancing the overall aesthetic and functionality of the final products.

Some products for reference

Packing and shipping

FAQs:

Q: How do POM-like vacuum casting parts compare to traditional POM parts?

A: Our POM-like parts offer similar properties to traditional POM, including wear resistance and dimensional stability, while providing the advantages of vacuum casting such as lower tooling costs and faster production times.

Q: Can you produce custom designs?

A: Absolutely! We specialize in creating custom products tailored to your specific requirements.

Q: What is the minimum order quantity?

A: We can accommodate both small and large orders. Contact us for a quote based on your needs.

Q: How long does production take?

A: Typical lead times range from 5-15 days, depending on the complexity and quantity of the order.

Q: Do you offer prototyping services?

A: Yes, we provide rapid prototyping services to help you validate your designs before moving to full production.

YOU MAY LIKE

_1744788508965.png)