Product Details

Category:Plastic vacuum casting

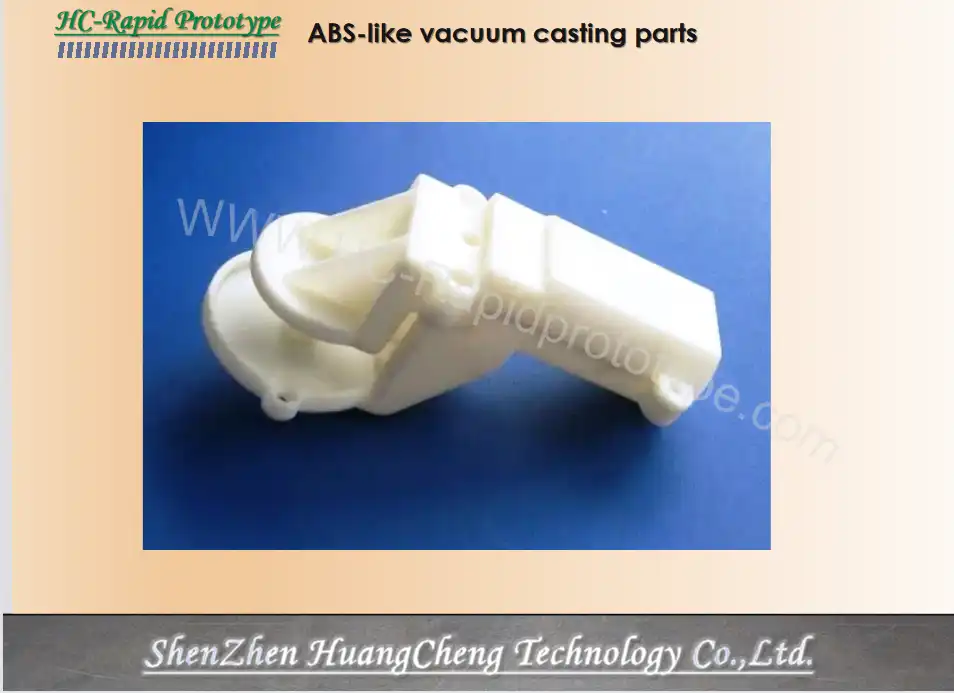

Product name: ABS-like vacuum casting parts

Material: Hei-Cast 8150, PX223-HT, DPI/UP 6160.

Surface treatment: deburring, oil injection, silk screen printing, etc.

Schedule: 3-7 seven working days

Drawing format: PDF, DWG, STP, DXF, STEP, IGS, XT and so on

ABS-like Properties

The following vacuum casting polyurethane resins all have similar properties to ABS-like vacuum casting parts, but their temperature resistance grades and their inherent properties are somewhat different. They can be used for shape confirmation and strength confirmation of injection molded parts, and can also be used for products. Small batch production.

The characteristics of the Hei-Cast 8150 are:

• Good physical properties manifest in this material's robust mechanical attributes. It exhibits remarkable tensile and compressive strength, along with excellent flexibility, making it suitable for a wide range of demanding applications.

• The fast curing speed of this substance significantly boosts production efficiency. It swiftly transforms from a malleable state to a solid form, reducing waiting times and accelerating the overall manufacturing process.

• The finished products showcase high dimensional accuracy, ensuring that each component adheres precisely to the design specifications. This precision is crucial for seamless integration in complex assemblies.

• With a temperature resistance of around 70℃, this material maintains its structural integrity and performance within this thermal range. It can withstand moderate heat without deforming or losing its functional properties.

• Sufficient practical strength enables this material to endure real - world stresses and strains. Whether subjected to heavy loads or repetitive forces, it remains reliable and durable, meeting the rigors of various operational environments.

The features of the PX223-HT are:

• The low viscosity of this material renders it highly fluid, facilitating effortless pouring into molds of various shapes and sizes. Its user - friendly nature simplifies the operational process, allowing both novice and experienced users to handle it with ease.

• Boasting excellent flexural strength, it can resist bending forces without deforming or breaking. Coupled with remarkable impact resistance, it withstands sudden shocks, making it ideal for applications where mechanical stress is prevalent.

• With a temperature resistance exceeding 120℃, this material remains stable and functional even in high - heat environments. It does not degrade or lose its mechanical properties, ensuring consistent performance under elevated temperatures.

• This substance causes minimal corrosion to silicone rubber molds, preserving their integrity and extending their lifespan. This not only reduces maintenance costs but also ensures that the molds can be used for multiple production cycles without significant wear.

The characteristics of the DPI/UP 6160 are:

• Good thermal resistance (close to 200℃) endows this material with the ability to maintain its structural integrity and performance even in extremely high - temperature environments. It resists heat - induced deformation and degradation, making it suitable for applications where exposure to intense heat is common.

• Being easy to paint, this material allows for seamless surface coating. Whether it's for aesthetic enhancement or protective purposes, paints adhere well to its surface, enabling quick and hassle - free customization of products.

• The ease of processing of this material simplifies the manufacturing workflow. It can be molded, cut, and shaped with relative simplicity using standard tools and techniques, saving time and reducing production complexity.

• Good reproduction accuracy ensures that every detail of the original design is faithfully replicated. This high - precision feature guarantees consistent quality across multiple products, making it ideal for applications that demand intricate and accurate manufacturing.

Introduction

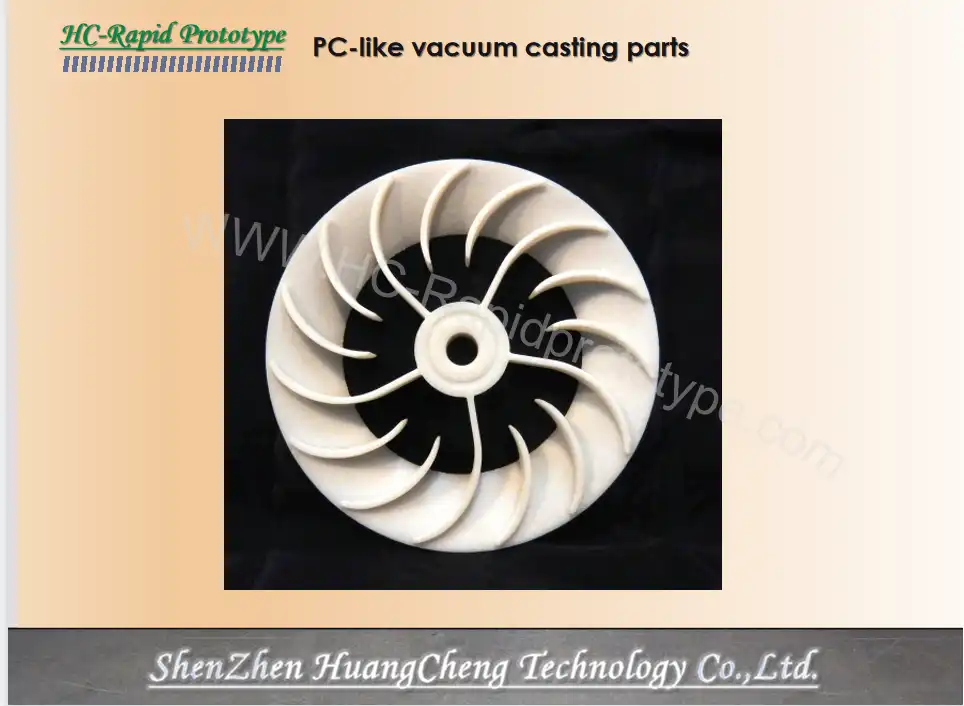

Compared with other prototype processes, the advantages of vacuum casting have the following characteristics: no complex mold creating, low processing cost, short production cycle, high similarity( close to 99.8%), suitable for small batch production etc., It is favored by high-tech industries.

More ABS-like vacuum casting parts for reference

Advantages

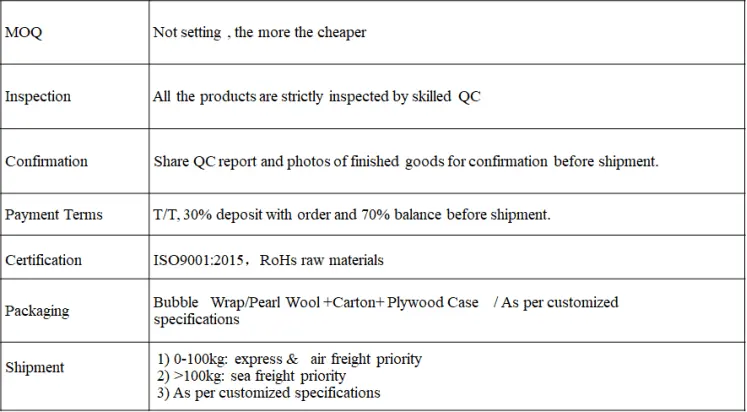

1. Our management and production executed strictly according to ISO9001 quality System.

2. Localized resources ensure competitive prices and high-quality prototyping solutions.

3. If there is a quality problem, we will supply the replacement.

4.Direct prototyping manufacturers without middlemen to make the difference will help you save costs

5.Natural geographical advantages, advanced equipment and professional technology to guarantee high-efficiency service.

Delivery and shipment

FAQs

Q1: How you guarantee the quality?

A1: Our prototype will be strictly complied with the requirements on drawing. We offer details photos

and QC report to let you confirm before shipment.

Q2: How to place an order to you?

A2:By email or below message transmission.

YOU MAY LIKE

_1744788508965.png)