Product Details

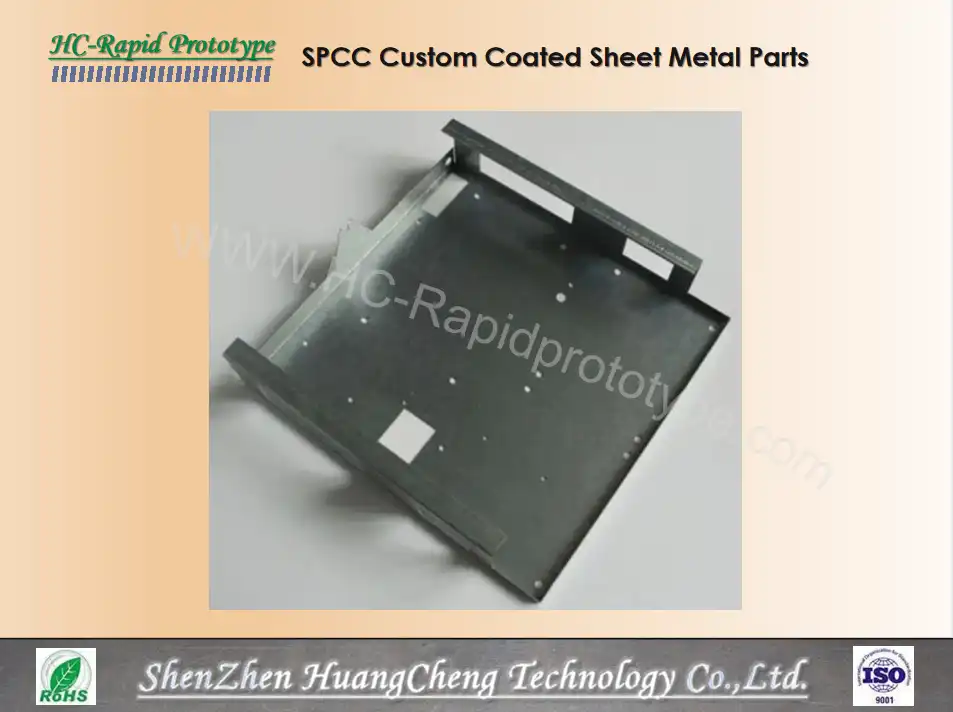

Product: SPCC Custom Coated Sheet Metal Parts

Surface finish: Powder coating, painting, Zinc-plated.

Processing : deburring, laser cutting, bending, shearing, welding

Application: computer, optical instrument

Tolerance: ISO2768-m / Refer to provided drawing

Delivery time: 5-12 working days.

Introduction

SPCC Custom Coated Sheet Metal Parts, which stands for Steel Plate Cold rolled Commercial, is a type of cold-rolled carbon steel sheet or strip. The naming convention provides clear information about the material and its characteristics. In the term SPCC, “S” denotes steel, indicating the base material; "P" signifies plate, which describes its shape, type, and typical usage. Typically, numbers are used in conjunction with this designation to denote the serial number of the steel or the lower limit of the steel strength value, offering further details about its properties. In actuality, despite the fact that the steel plate heats up during the cold rolling process, it is still classified as cold rolling. Cold-rolled products formed through hot rolling and continuous cold deformation often exhibit poor mechanical properties and high hardness. To restore their mechanical properties and make them suitable for manufacturing desired products, these materials must undergo annealing. On the other hand, those that are not annealed are referred to as hard-rolled coils. Hard-rolled coils are predominantly utilized in the production of items that do not require bending or stretching operations, such as certain types of simple structural components or parts where the high hardness can be an advantage rather than a limitation.

Uses of SPCC

- SPCC is widely employed in the fabrication of steel structural parts. Its properties make it suitable for constructing bridges, ships, and vehicles, providing the necessary strength and durability for these large - scale and crucial applications.

- SPCC contains special elements like P, Cu, and C. This composition endows it with excellent corrosion and atmospheric corrosion resistance, making it ideal for manufacturing containers, special vehicles, and certain building structures that need to withstand environmental exposure.

- As a high - strength steel plate, SPCC offers good stamping and welding capabilities. These features enable its use in producing essential automotive components such as the vehicle frame and wheels, ensuring structural integrity and performance.

- The majority of carbon steel, alloy steel, and tool steel undergo heat treatment before being utilized in the production of diverse mechanical parts. This process enhances their mechanical properties for specific functional requirements.

SPCC Custom Coated Sheet Metal Parts for Information

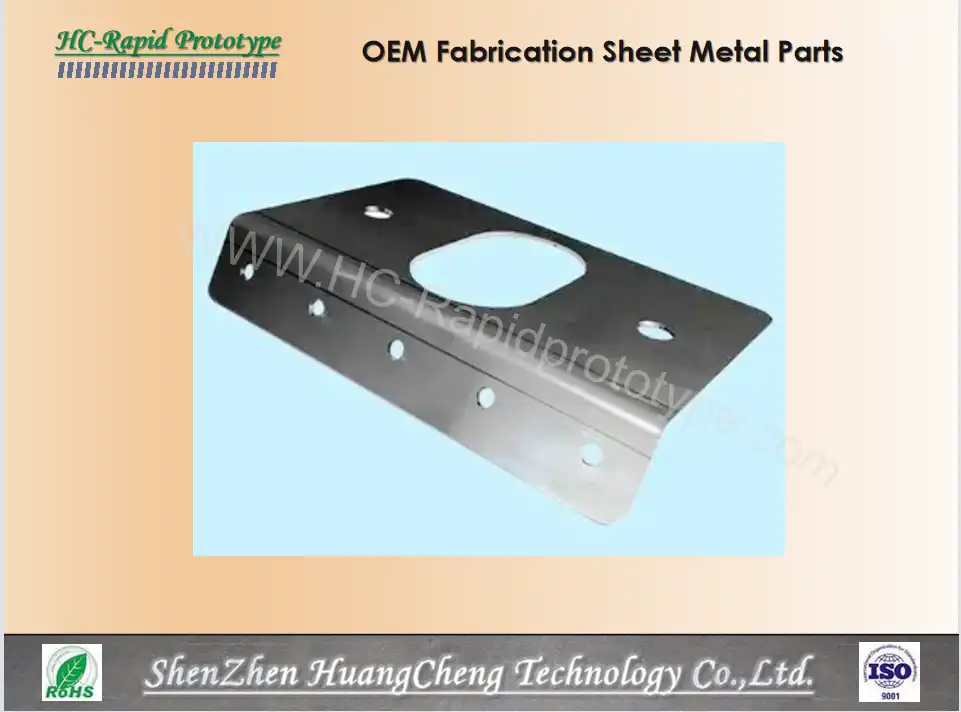

HC-Rapidprototype Advantage and Service

- State-of-the-art CNC machining and laser cutting technology empower us to achieve unparalleled precision and efficiency. Our advanced CNC machines can handle complex geometries with ease, while laser cutting ensures clean, accurate cuts on a wide range of materials, meeting the most demanding project requirements.

- In-house coating facilities for streamlined production allow us to integrate the coating process seamlessly into our manufacturing workflow. This not only reduces lead times but also ensures consistent quality, as we can closely monitor and control every aspect of the coating operation.

- Rigorous quality control measures at every stage guarantee that our products meet the highest standards. From raw material inspection to final product testing, multiple checks and inspections are carried out to identify and rectify any potential issues promptly.

- Rapid prototyping and small-batch production capabilities enable us to quickly turn ideas into reality. Using 3D printing and other fast prototyping methods, we can produce functional prototypes for testing and validation, and then smoothly transition to small-batch production.

- Expert engineering support for design optimization means our experienced engineers work closely with clients from the start. They use their knowledge and skills to refine designs, improve functionality, and ensure manufacturability, adding significant value to every project.

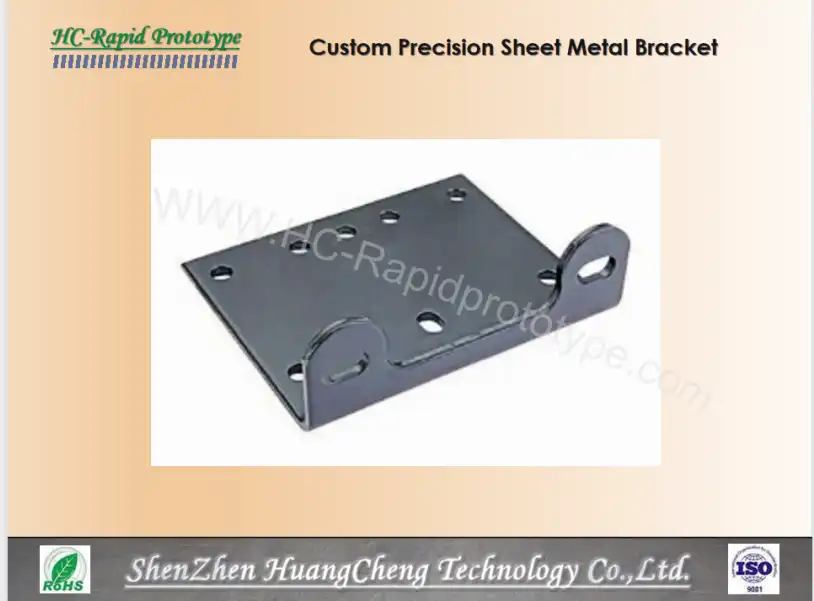

Product Characteristics

- Superior surface finish is achieved through advanced manufacturing techniques and meticulous post - processing. Our products feature smooth, flawless surfaces that not only enhance aesthetic appeal but also reduce friction and improve performance in various applications.

- Excellent formability and weldability make our materials highly adaptable for diverse manufacturing processes. They can be easily shaped into complex designs and joined securely, enabling efficient production of intricate components with reliable structural integrity.

- Enhanced corrosion resistance is a key advantage of our materials. With specialized coatings and treatments, they offer long - lasting protection against rust and degradation, ensuring durability even in harsh environmental conditions.

- Consistent quality across large production runs is ensured by our strict quality control systems. Rigorous inspections and standardized processes at every stage guarantee that each product meets the same high - level specifications, providing reliability for mass production.

- Cost - effective solution for complex designs is provided by optimizing our manufacturing processes. We balance quality and affordability, leveraging innovative techniques to produce intricate designs without incurring excessive costs for our customers.

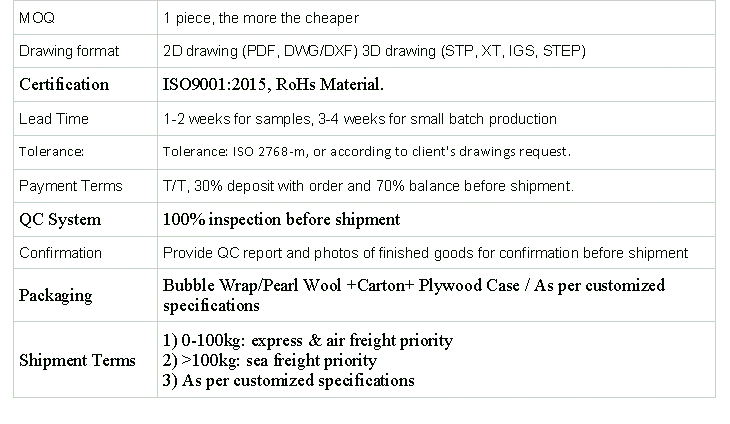

Deliver Information

FAQs

Q1: How can I get your quotation?

A1: Please send your design drawings or samples to us with your detailed requirements.

Usually, you can get our quotation within 48 hours, while it depends on the workload.

Q2: Can I have a trial order or samples only for several pieces?

A2: The customized samples cost us several hours or more, so it should be charged. If the sample

is unqualified or a mass order is released, we will refund the sample cost.

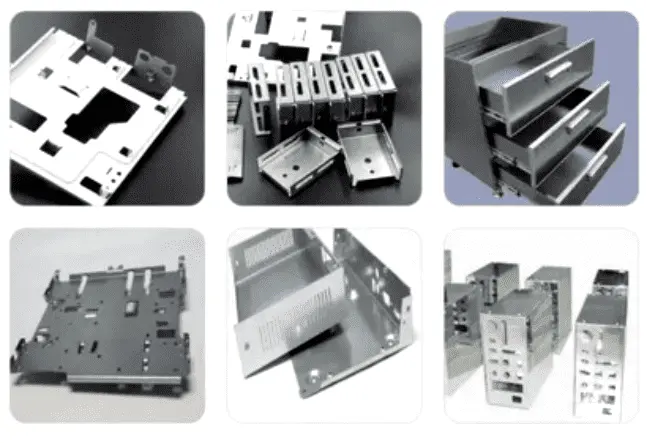

YOU MAY LIKE

_1744788508965.png)