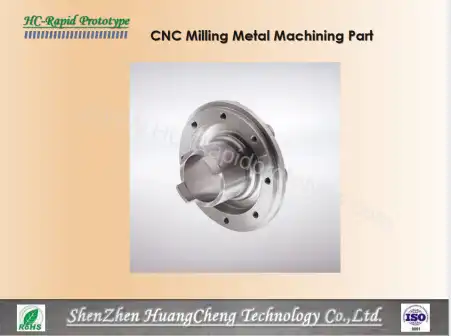

Product Details:

Material: Brass, Bronze, Copper, Hardened metals, Stainless steel , Aluminum alloy etc.

Surface Treatment: Passivation, anodized, Zinc-plated

Processing Method: CNC machining, CNC milling, drilling, tapping.

Application Industry: Automotive, Medical, Aerospace, Military

Tolerance: ISO 2768-m, or refer to customer drawings request.

Delivery time: 5-10 working days.

Applications:

Widely used in aerospace & flight, automotive, chemical manufacturing, clocks, electronic devices, enclosures, engines, furniture, food processing, lighting, materials handling, medical, models, nameplates, oil drilling, oil refinery, optical equipment, robotic equipment, semiconductor manufacturing, underwater seismology, water & waste treatment, watercraft and so on.

Introduction:

We design, manufacture and assemble all kinds of different metal parts according to customers' design or drawing and requirements. Also , we are experienced in CNC machining, can manufacture a wide variety of CNC Milling Metal Machining Parts and othe metal components for a variety of industries.

HC-Rapidprototype has the competitive advantage of equipment and technology, it is ISO9001: 2015 certificated company good at design and manufacture all kinds of rapid prototypes , such as CNC machining , sheet metal , vacuum casting , EDM discharge , 3D printing and surface finishing etc. We are expert for CNC Milling Metal Machining Part, The main used material are aluminum, carbon steel, alloy steel, stainless steel, copper , brass and others metal materials. Please contact us freely , we will try our best to offer your top service and good quality products.

Key Characteristics of Our CNC Milled Parts:

- Precision Engineering: Ideal for aerospace brackets, automotive components, or medical device housings requiring micron-level accuracy. Our precision engineering services utilize state-of-the-art equipment and advanced techniques to achieve micron-level accuracy, making us the perfect choice for manufacturing critical components in aerospace, automotive, and medical industries.

- Scalable Production: Seamlessly transition from prototypes to 10,000+ unit runs with consistent quality. Equipped with flexible manufacturing systems and a skilled workforce, we can smoothly move from producing initial prototypes to large-scale production of over 10,000 units while maintaining unwavering quality standards.

- Customization: Tailored surface treatments, material grades, and packaging to match your specifications. We understand that each project is unique. That’s why we offer customized solutions, including specific surface treatments, material grades, and packaging options, all designed to precisely meet your individual requirements.

Our Productive Process:

- Design Review: Our engineers optimize your CAD files for manufacturability and cost efficiency. Our seasoned engineering team meticulously analyzes your CAD files, identifying potential manufacturing challenges and areas for cost savings. Through strategic modifications, we enhance the design's manufacturability, streamlining production and reducing expenses.

- CNC Machining: State-of-the-art 5-axis machines handle intricate designs and tough materials. Equipped with advanced 5-axis CNC machines, we can effortlessly machine complex geometries and work with a variety of hard-to-cut materials. These machines ensure high precision and efficiency in producing even the most elaborate CNC Milling Metal Machining Parts.

- Quality Checks: In-process inspections using CMM machines and material traceability reports. Throughout the manufacturing process, we conduct regular in-process inspections with Coordinate Measuring Machines (CMM) to verify dimensional accuracy. Alongside this, we maintain detailed material traceability reports, ensuring full quality control and accountability.

- Post-Processing: Dedicated workshops for polishing, electroplating, or laser marking. Our specialized post-processing workshops are fully equipped to perform a range of operations, including polishing for a smooth finish, electroplating for enhanced durability and appearance, and laser marking for precise identification and decoration.

- Delivery: Global logistics partners ensure safe, on-time delivery. We have established strong partnerships with reliable global logistics providers. Their expertise and extensive networks enable us to ensure that your products are shipped safely and reach you exactly when promised, anywhere in the world.

Remark:

|

Lead time for sample |

5-7 working days |

|

Lead time for orders |

12-15 working days |

|

Shipping |

DHL, FedEx, UPS,TNT, by air or by sea |

|

Packing |

Bubble Wrap/Pearl Wool + Strong Carton + Plywood case |

|

Sea Port |

Guangzhou / Shenzhen/ Hongkong |

|

Payment term |

T/T, 30% deposit,70% before shipment (finished goods confirmation done) |

|

Trade terms |

EXW, FOB, CNF,CIF, DDU, As per customer's request |

|

Drawing format |

JPG,PDF,DWG,DXF,STEP,IGS etc. |

FAQs:

Q1: Is there any discount for bulk orders?

A1: Yes, bulk orders are welcomed. And we will be glad to offer you better price discounts based on your order quantity.

So please feel Free to contact us when you need to take large order quantities or customized products.

Q2: Is there any spare CNC Milling Metal Machining Parts service if the order is large?

A2: Of course, we will evaluate the quantity of spare parts according to your order.

YOU MAY LIKE

_1744788508965.png)