Product Details

|

Name |

CNC Turning and Milling Plastic Parts |

|

Accuracy |

Up to +/-0.02mm |

|

Tolerance |

ISO 2768-m or drawing |

|

Material |

Nylon, POM,Delrin, PEEK,PVC,PC, Acetal,PA,PMMA,UHMW,Bakelite |

|

Color for plastic |

white, green, black ,grey,blue,red, yellow and so on. |

|

Shipment |

by DHL/ Fedex , if need urgent, also can by road or by sea if want to save transport cost. |

Introduction

HC-Rapid prototype is specialized in manufacturing plastic CNC machining parts for Medical equipments and Electro-Optics . also suitable for short runs of products that will be converted to injection molding. The plastic material we process often: Nylon, POM,Delrin, PEEK,PVC,PC, Acetal,PA,PMMA,UHMW,Bakelite The main material color for plastic are : white, green, black ,grey,blue,red, yellow etc.

Plastics are organic polymers of high molecular mass, usually synthetic, most commonly derived from petrochemicals, but many are made from renewable materials such as polylactic acid from corn or cellulosics from cotton linters. Plasticity is the general property of all materials that are able to irreversibly deform without breaking.

For plastic part ,it is very easy to happen deformation when processing the plastical material. Our skilled team of engineering technicians will use a range of the latest, high-end, and precision CNC milling and turning equipment to machining products. control the deformation to be Min and keep the tolerance within the drawings' request.

*Partial CNC Turning and Milling Plastic Parts for reference

Product Characteristics:

- High dimensional accuracy

- Excellent surface finish

- Complex geometries achievable

- Consistent quality across large production runs

Production Process:

1. CAD/CAM design and optimization

2. Material selection and preparation

3. CNC machining (turning and milling)

4. Quality inspection and testing

5. Post-processing (if required)

6. Packaging and shipping

Applications:

Our products are widely used in:

- Automotive components

- Aerospace parts

- Medical device manufacturing

- Consumer electronics

- Industrial machinery

Why Choose ShenZhenHuangCheng Technology Co., Ltd.?

1. Expertise: Our team of skilled engineers and technicians brings years of experience to every project.

2. Advanced Technology: We invest in cutting-edge CNC machinery to ensure the highest quality output.

3. Flexibility: We can accommodate both small prototype runs and large-scale production orders.

4. Cost-Effectiveness: Our efficient processes and local sourcing help keep costs competitive.

5. Quality Assurance: Rigorous quality control measures ensure consistent, high-quality parts.

Our Advantages

1. Advanced equipment

We have the high quality CNC and EDM machines , such as : 4-axis and 5-axis CNC machines , can offer stable and accurate processing ability

2. High Quality and Factory price

We have ISO9001 international quality management system, as well as Chinese production cost control experience , so we can help you save about 20%~30% manufacturing cost when you compare with others.

3. Fast delivery time

Our mold workshop have two turns each day, our worker/engineer work for 8 hours , we can achieve the delivery time of 3-5 working days for prototype, 7-10 working days for low-valume production.

Remark

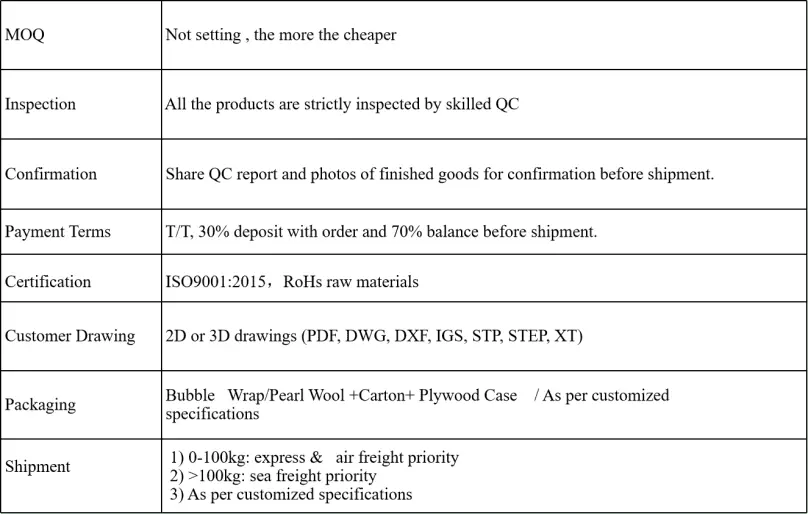

About some other information please refer to below table.

FAQ

Q:Why use and machine plastics?

A:One of main reasons is the rising costs ofmetal. This leads many to seek ways to replace machined metal partswith plastics. As a result, CNC job shops are seeing an increase in requests for plastic parts by their customersMost quality stock shape materials are stress relieved to ensure the highest degree of machine ability anddimensional stability, However, the relative sofmess of plastics (compared to metals) generally results ingreater difficulty for maintaining tight tolerances during and after machining. A good rule of thumb fortolerances of plastic parts is +/. .001 per inch of dimension although tighter tolerances are possiblewith very stable, reinforced materials.

Q: What is the minimum order quantity for CNC turning and milling plastic parts?

A: We can accommodate orders of various sizes, from single prototypes to large production runs. Contact us for a custom quote.

Q: How long does it take to produce CNC turned and milled plastic parts?

A: Lead times vary depending on the complexity and quantity of the order. Typically, we can deliver within 1-3 weeks. Rush orders may be available upon request.

Q: Can you work with my custom designs?

A: Absolutely! We offer design optimization services to ensure your parts are manufacturable and cost-effective.

Q: Do you offer assembly services for complex parts?

A: Yes, we can provide assembly services for multi-component parts or products.

Q: How do you ensure the quality of your CNC turned and milled plastic parts?

A: We employ strict quality control measures throughout the production process, including advanced inspection equipment and trained quality assurance personnel.

YOU MAY LIKE

_1744788508965.png)