Product Details

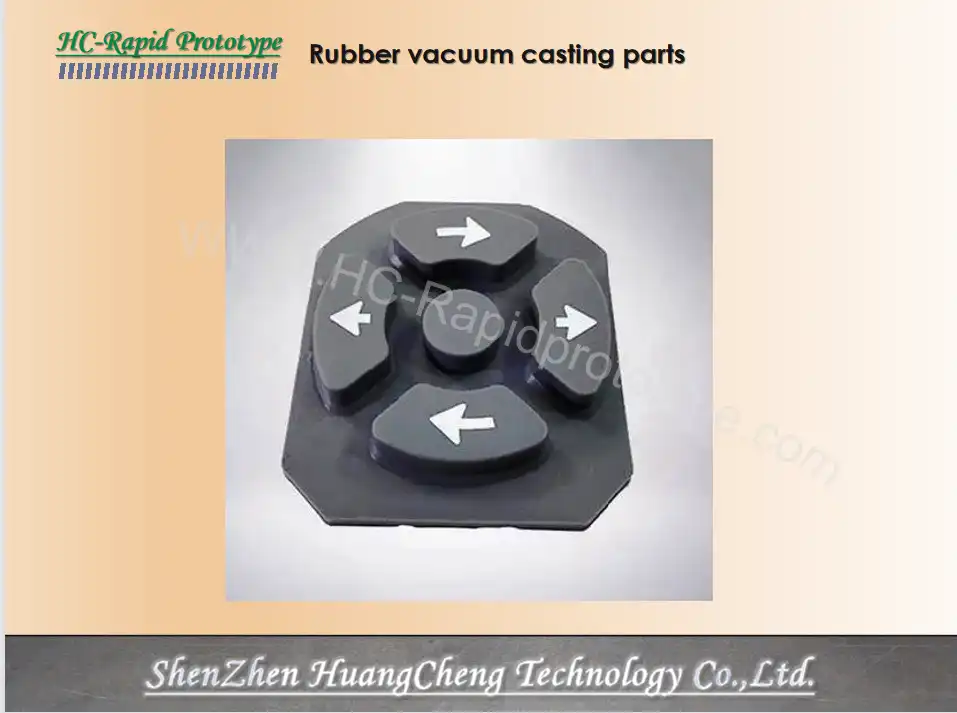

Product: Rubber vacuum casting parts

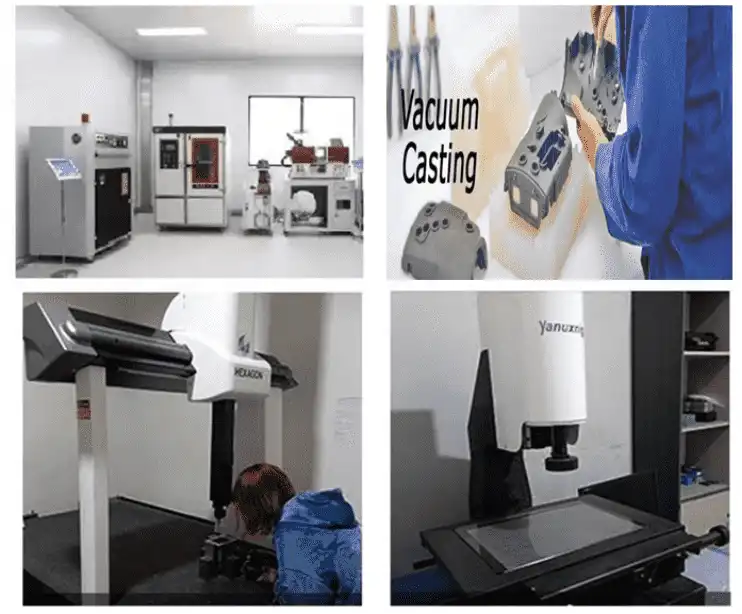

Processing method: Vacuum casting

Material: Hei-Cast 8400、8400N

Surface treatment: deburring, silk screen, etc.

Processing time: 3-10 working days

Refer to: Customer 2D/3D drawings

Product features: no mold, low production cost, fast delivery, can be customized in small batches

Hei-Cast 8400 and 8400N properties

Hei-Cast 8400 and 8400N are 3-component polyurethane elastomers for vacuum casting. Has the following characteristics.

(1) The hardness of Type A can be freely chosen within the range of 10 to 90 by simply adding the "C component". This adjustable feature allows for customization to meet diverse application requirements.

(2) With low viscosity and remarkable fluidity, the material can easily fill complex molds, ensuring precise replication of intricate details and smooth surfaces in the final products.

(3) It boasts excellent curability, enabling quick and efficient solidification, and outstanding resilience, ensuring the products maintain their shape and performance even after repeated deformations.

(4) This material is perfectly suitable for small - batch production. Whether it's for prototyping or limited - quantity manufacturing, it offers reliable performance and quality.

(5) Regarding the product color, customers have the option to choose between classic black or clean milky white, providing flexibility to match different aesthetic and design needs.

Introduction

Rubber, a versatile and essential material, is primarily categorized into natural rubber and synthetic rubber. Natural rubber is derived from the milky colloidal sap extracted from plants such as rubber trees and rubber grass. This raw sap undergoes a series of meticulous processing steps, including coagulation, washing, and drying, to transform it into a usable form. In contrast, synthetic rubber is produced through the polymerization of various monomers in chemical plants. This manufacturing process allows for the creation of rubbers with customized properties tailored to specific applications. Rubber products have permeated every aspect of modern life and industrial operations. In the industrial realm, they are crucial components in machinery, automotive parts, and construction materials, providing durability, flexibility, and shock absorption. In daily life, rubber is found in countless items, from tires and seals to consumer goods like footwear and kitchen utensils. Silica gel, often simply referred to as silicone rubber, is a specialized and highly valuable variety within the rubber family. Renowned for its unique characteristics such as high temperature resistance, excellent electrical insulation, and biocompatibility, silicone rubber has carved out a niche in numerous high - tech and specialized applications, including medical devices, aerospace components, and electronics.

Advantages of rubber

1). Great elasticity endows this material with the ability to undergo significant deformation even under minimal external force. Once the force is removed, it promptly reverts to its original form, ensuring consistent performance and shape retention.

2). Being artificially synthesized, it eliminates the constraints of natural resources. This not only enables large - scale production but also keeps the price remarkably low, making it a cost - effective choice for various applications.

3). It showcases outstanding physical and mechanical properties, guaranteeing durability and strength. Coupled with excellent chemical stability, it resists degradation from a wide range of substances, enhancing its longevity.

4). With remarkable resistance to oil, water, solvents, and high - pressure oil, it thrives in harsh environments. Its good compressibility, wear resistance, and elongation force ensure reliable functionality under diverse conditions.

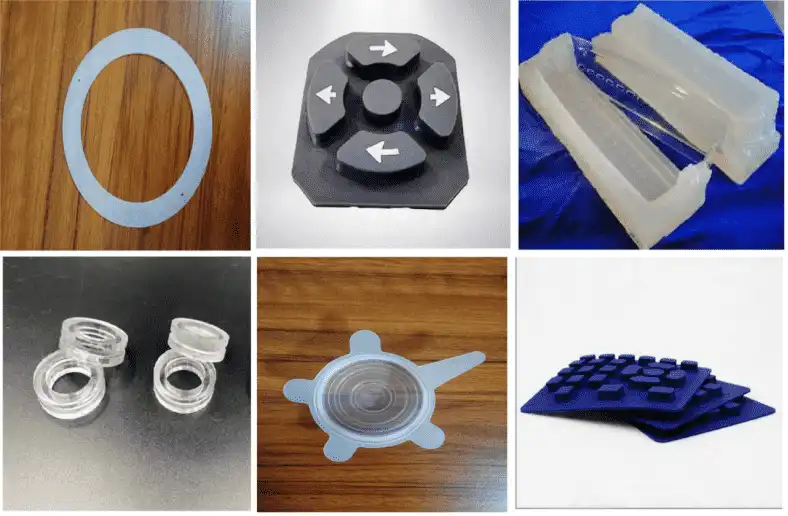

Rubber application range

Widely used in the manufacture of tires, hoses, tapes, cables and other various rubber products.

Advantages

Rubber vacuum casting parts have below advantages:

- The production cost is extremely low. Without the need for expensive tooling and complex machinery, the processing cost is significantly lower than CNC machining and 3D printing, making it highly cost - effective for businesses.

- The production cycle is notably short. By eliminating the time - consuming mold - creating process, it streamlines the overall production flow, thus greatly enhancing production efficiency and accelerating product delivery.

- With free mold services, it saves precious time that would otherwise be spent on mold creation. This allows customers to gain a head start in new product development and seize lucrative market opportunities promptly.

- It offers a high degree of similarity to the original design, minimizing the risk of processing failures. The reliable process ensures consistent and accurate results in every production run.

- Ideal for small batch production, it features a short customization time and low cost. This makes it a flexible solution for businesses looking to produce limited quantities of customized products.

- The workmanship is exquisite and meticulous, resulting in products with no burrs. This high - quality finish not only improves the appearance but also enhances the functionality and usability of the products.

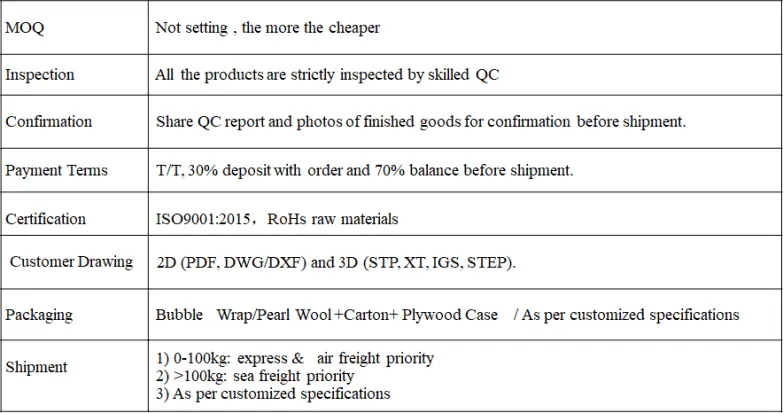

Delivery Message

FAQs:

Q: What is the minimum order quantity for products?

A: We offer flexible MOQs to accommodate your needs, starting from as low as 10 pieces for prototyping.

Q: Can you produce products with complex geometries?

A: Absolutely! Our advanced technology allows us to create intricate designs with high precision.

Q: What is the typical lead time for the products?

A: Lead times vary depending on complexity and quantity, but we generally deliver within 5-15 working days.

Q: Do you offer design optimization services for the products?

A: Yes, our experienced engineers can provide valuable input to optimize your designs for manufacturability and performance.

Q: Can you match specific color requirements for rubber vacuum casting parts?

A: Certainly! We offer custom color matching to ensure your parts meet your exact specifications.

YOU MAY LIKE

_1744788508965.png)