Product & service

1. Custom Galvanized Steel Sheet Metal Parts: according to customer’s drawing or Sample

2. Tolerance: within +/-0.1mm. or ISO2768-m

3. More than 10 years’ Experience in Sheet Metal fabrication Industry

4. Fast delivery: 5-10 working days lead time for prototypes

5. Good communication before Production and give advice on how to improve on Customer's design.

6. Quality assurance in accordance with ISO9001:2015. RoHs materials.

Introduction

For custom galvanized steel sheet metal parts, there are two different materials can be chosen, one is galvanized steel sheet SECC and the other is hot dip galvanized steel sheet SGCC. They each have different characteristics:

1. Galvanized steel SECC

The substrate of SECC (Steel Electrolytically Chromated Coated) is ordinary cold-rolled steel coil. In a continuous electro-galvanizing production line, this base material undergoes a series of meticulous processes. First, degreasing is carried out to remove any contaminants and oils on the surface. Then, pickling helps to further clean and prepare the steel for electroplating. During electroplating, a thin, even layer of zinc is deposited on the steel. Various post-treatment steps follow to enhance the quality and durability of the coating. As a result, SECC not only retains the mechanical properties and workability of ordinary cold-rolled steel sheets, allowing for easy shaping and fabrication, but also offers superior corrosion resistance and an attractive decorative appearance. This makes it highly competitive and a popular choice in the markets of electronic products, home appliances, and furniture. For instance, the commonly used computer case is often made from SECC, taking advantage of its strength, corrosion resistance, and good looks.

2. Hot dip galvanized steel sheet SGCC

Hot-dip galvanized steel coil, also known as SGCC (Steel Sheet, Zinc Coated by Hot-dip Process), starts as a semi-finished product that has undergone either hot-rolled pickling or cold-rolling. The manufacturing process begins with thorough cleaning to remove surface impurities, followed by annealing to improve the material's internal structure and make it more malleable. Subsequently, the steel sheet is immersed in a molten zinc bath heated to approximately 460 °C. This high-temperature immersion ensures that a thick, adherent zinc layer coats the steel, providing robust corrosion protection. After the zinc coating, the material undergoes quenching and tempering to enhance its hardness and strength, flattening to achieve a smooth surface, and chemical treatment to further optimize its properties. Compared to SECC, SGCC is harder, with reduced ductility that makes deep drawing processes challenging. Its thicker zinc layer offers enhanced corrosion resistance, but this comes at the cost of poorer weldability, limiting its use in applications that require extensive welding.

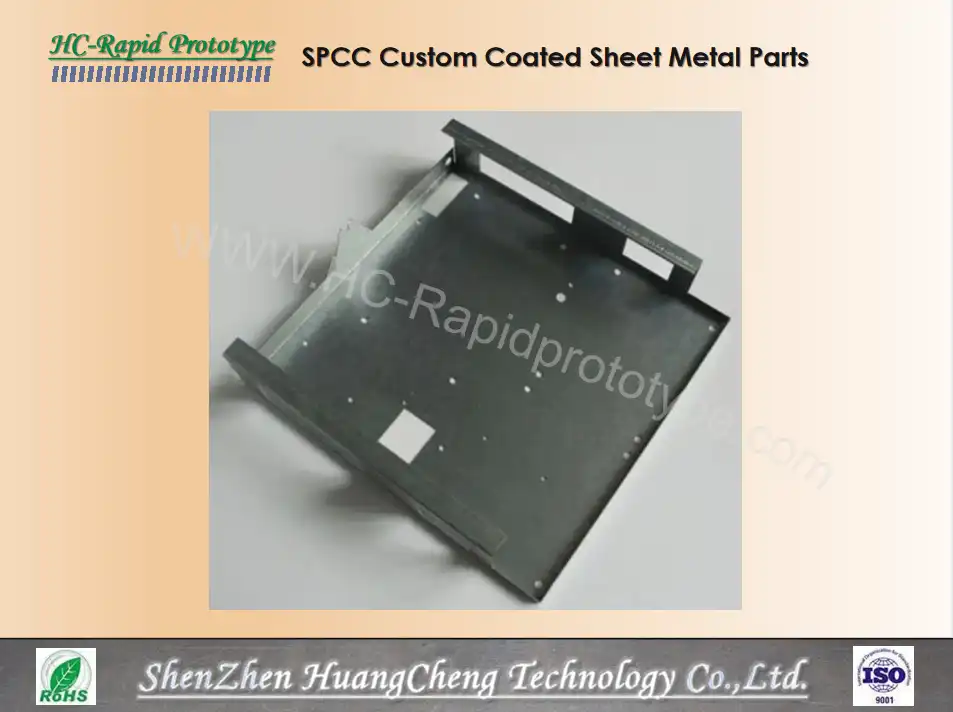

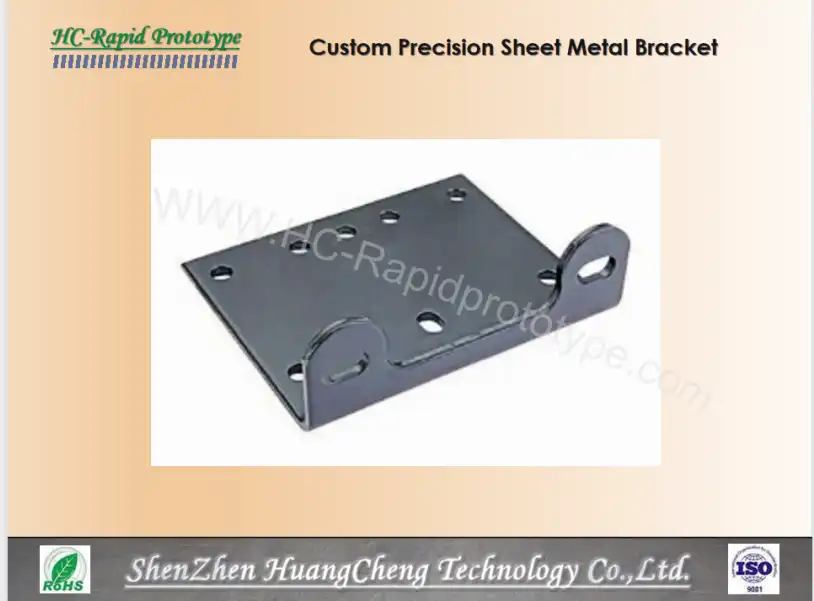

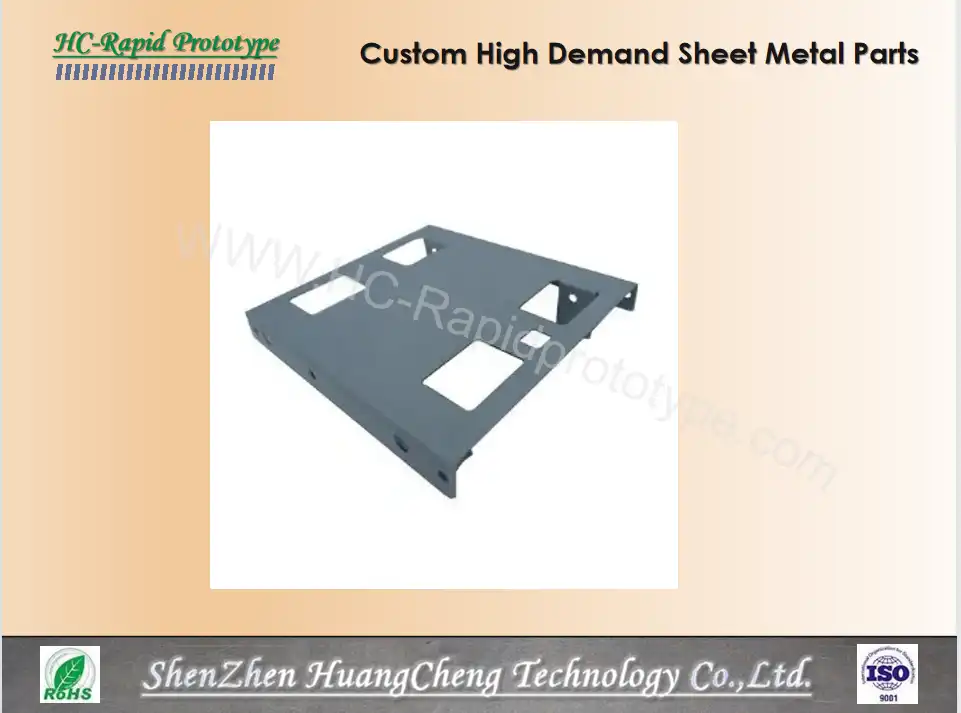

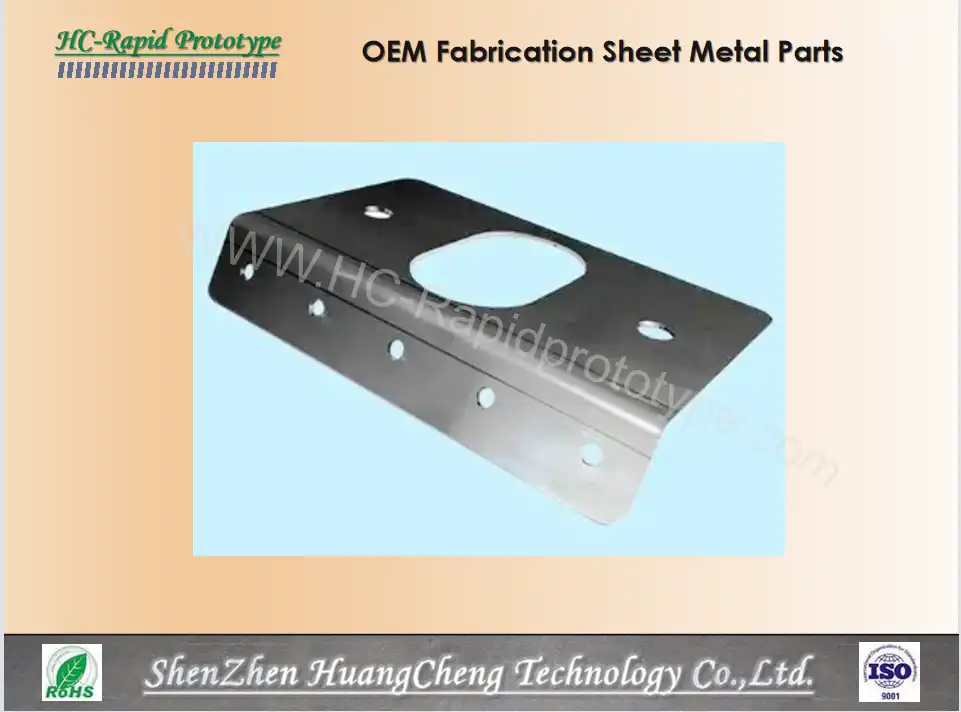

Partial custom galvanized steel sheet metal parts for reference

HC-Rapidprototype Advantage:

- State-of-the-art CNC machining centers and 3D printers

- In-house electroplating and polishing facilities

- Rigorous quality control throughout production

- Fast turnaround times and on-time delivery

- Competitive pricing without compromising quality

Product Characteristics:

- Excellent corrosion resistance

- High strength-to-weight ratio

- Versatile for various applications

- Customizable designs and sizes

- Durable and long-lasting

Comment

1. Product manufacturing will be followed up by professionals.

2. Competitive Price directly from the original manufacturer.

3. Professional QC and R&D teams to assure high quality,

4. Respond quickly and keep pace with the customer's time.

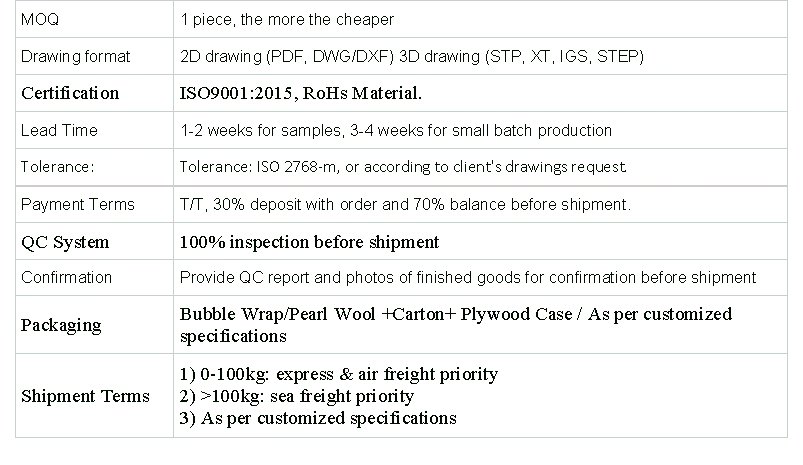

Delivery Information

FAQs

Q1:What need you do if I want to print my own logo?

A1: First, please send us your logo file in high resolution. We will make some drafts for your reference to confirm the position and size of your logo. Next we will make 1-2 samples for you to check the actual effect. Finally the formal production will start after the sample confirmed.

Q2: How does your company do regarding quality control?

A2: Our quality inspectors have IQC IPQC OQC QE will do strict quality control inspection before shipment to assure best quality

YOU MAY LIKE

_1744788508965.png)