Product Details

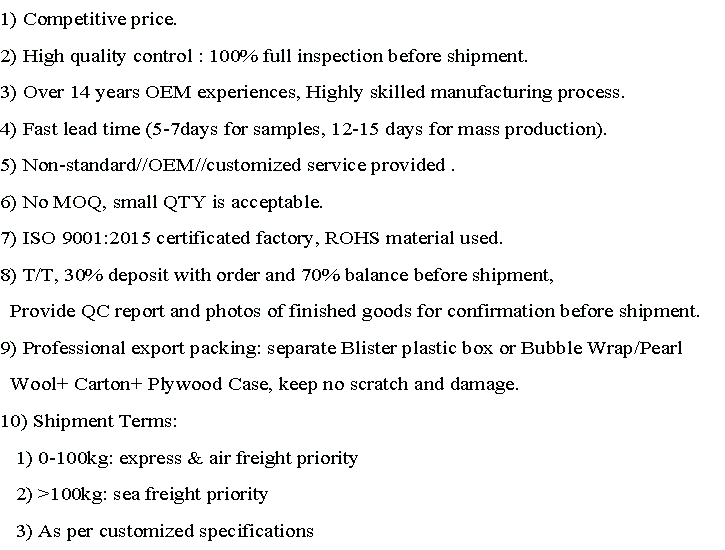

Product: SLA 3D printing parts

Size: Refer to customer drawing or golden sample

Material: Accura Xtreme,RenShape SL7820 ,MicroFine,WaterShed XC 11122,Somos 9120,Accura 60,Accura 5530 etc.

Finishing: Polishing, tinting, surface marking etc.

Application: Aerospace, Auto parts, office equipment, medical equipment etc.

Introduction

SLA 3D printing parts is one of the earliest 3D printing technologies, and also one of the most versatile technologies.

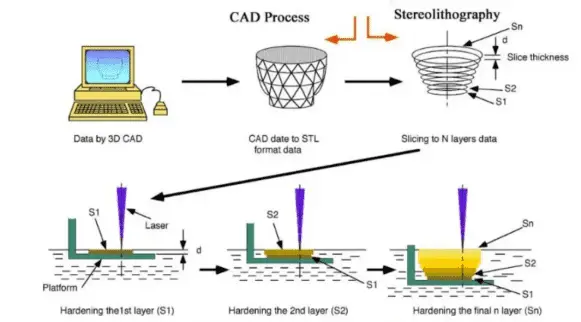

It builds the part layer-by-layer with light-cured resin, using a high-power UV laser focused on the build platform to cure one layer of material at a time. SLA offers a range of material options and provides a very accurate CAD and good surface finish for the part. and the parts need to be built with support structures that are removed after machining. SLA is a good choice for prototypes and low volume production.

SLA light curing 3D printer technology principle:

SLA Advantages

- The light curing molding method is the earliest rapid prototyping manufacturing process, which has a high degree of maturity and has passed the test of time. As the pioneering rapid prototyping technique, light curing molding has evolved over years, reaching a high maturity level. Its long - standing use attests to its reliability and effectiveness in diverse applications.

- Prototypes are directly made from CAD digital models, with fast processing speed and short production cycle, without cutting tools and molds. By directly transforming CAD digital models into prototypes, this method eliminates the need for cutting tools and molds. It offers a swift processing pace and a short production cycle, enabling quick design iterations.

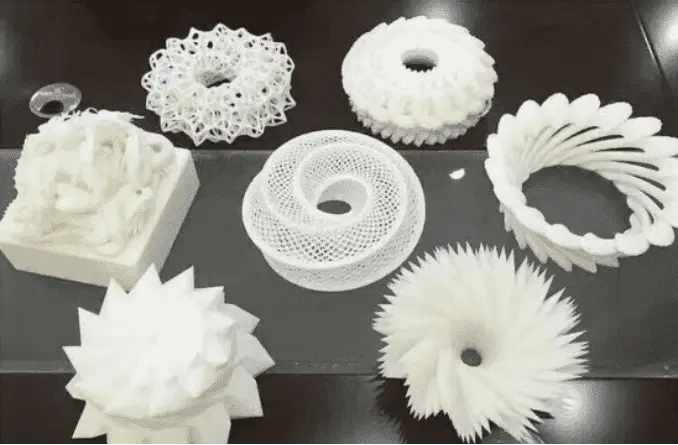

- Prototypes and molds with complex structures or shapes that are difficult to form using traditional methods can be processed. Capable of handling intricate structures and shapes, light curing molding overcomes the limitations of traditional techniques. It enables the fabrication of prototypes and molds that are otherwise challenging to produce.

- Visualize the CAD digital model and reduce the cost of error repair. This process brings CAD digital models to life, allowing for a tangible visualization. By identifying potential flaws early, it significantly cuts down on the expenses associated with error correction.

- Provide samples for experiments, which can verify and check the results of computer simulation calculations. Light curing molding supplies experimental samples that serve as a means to validate computer simulation outcomes. This practical verification ensures the accuracy of theoretical calculations.

- It can be operated online and controlled remotely, which is conducive to the automation of production. With online operation and remote control capabilities, light curing molding promotes production automation. This enhances efficiency and enables seamless integration into modern manufacturing setups.

SLA Characteristics

- Great for aesthetic models: SLA 3D printing parts is ideal for creating aesthetic models as it can accurately reproduce intricate details and smooth contours. Whether it’s for product design showcases or art installations, it can bring visual concepts to life with an appealing and refined look.

- Good surface finish/parts can be done: It offers an excellent surface finish, eliminating the need for extensive post - processing. The parts produced have a sleek and professional appearance, making them suitable for applications where surface quality is crucial.

- High precision and detail/resolution: With its high precision capabilities, it can achieve minute details and fine resolutions. This allows for the creation of parts with complex geometries and tiny features, ensuring that the final product meets exacting standards.

- Various materials, including transparent: A wide range of materials is available, catering to different project requirements. Notably, the option of transparent materials enables the fabrication of see - through components, expanding the possibilities for innovative designs.

- Fast and cheap: Compared to many other manufacturing methods, it offers a fast production turnaround, reducing lead times. Additionally, it is cost - effective, making it accessible for both small - scale projects and larger production runs without breaking the budget.

Delivery message

FAQ

YOU MAY LIKE

_1744788508965.png)