Introduction

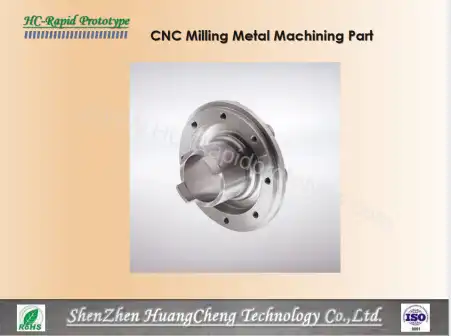

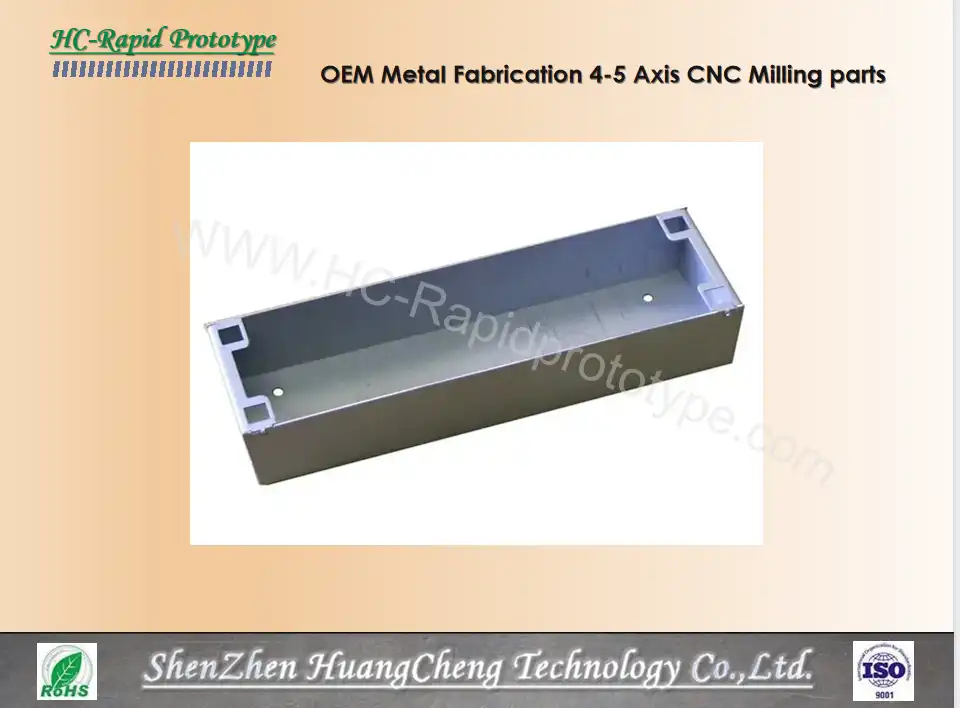

HC has the competitive advantage of equipment and technology, It is a professional manufacturer specialized in non-standard high precision parts. We have a professional business team, high quality products and affordable prices, and look forward to becoming your long-term partner.

HC-Rapidprototype capability

1. All Auto Industrial CNC Milling Aluminum parts produced according to your CAD and 3D drawings or sample. Please send the blueprint or drawing artwork firstly, we will offer our quotation to you within 8 hours.

2. Materials as below.

Aluminum, Stainless steel, brass, copper, Delrin, PVC,17-4pH, DERLIN, Carbamide alloy, PEEK and other materials.

3. The surface finished include:

Hardness anodizing black/clear, steel oxidizing dark-blue, electro-polishing, electroless nickel plating, silver plating, golden plating etc.

4. OEM&ODM are welcomed.

5. Packing: Wooden cases, carton or on requirement.

6. Main equipment:

Machining center, CNC, Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine Sheet metal machine , 3D printing machine for metal /plastic, vacuum casting etc.

7. Testing facility: Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester. Height tester, .

8. Part size: Diameter from 0.5mm to 150mm

9. Tolerance: +/-0.001mm

10, Lead time: 5-15 working days after the confirmation of sample

11: Minimum Order: Not setting , Comply with customer's demand

12, Delivery way: EXPRESS, BY SEA OR BY AIR on your requirement.

*More Auto Industrial CNC Milling Aluminum parts for your reference.

These products are showed here only to present the capability of our business activities,

We sincerely hope to cooperate with clients from all over the world and achieve a Win-Win situation.

HC-Rapidprototype Advantage and Service:

- Rapid prototyping and mass production capabilities: We combine cutting-edge 3D printing and advanced machining technologies for swift prototyping, then seamlessly transition to mass production. Our scalable processes ensure consistent quality across all production volumes.

- In-house design and engineering support: Our in-house team of experienced designers and engineers offers comprehensive support. They collaborate closely with you, optimizing designs for manufacturability and providing innovative solutions throughout the project.

- Competitive pricing without compromising quality: Through efficient production methods, bulk material purchasing, and streamlined operations, we keep costs down. This enables us to offer highly competitive prices while maintaining the highest quality standards.

- On-time delivery and responsive customer service: We prioritize punctuality with meticulous production scheduling and logistics planning. Our dedicated customer service team is always ready to promptly address any inquiries and ensure a smooth experience.

Product Characteristics:

- Excellent strength-to-weight ratio

- Superior corrosion resistance

- High dimensional stability

- Exceptional heat dissipation properties

- Suitable for complex geometries

CNC Machining process

(1) According to the part loading and positioning method: each part has different structural shapes, and the technical requirements of each surface are also different. Therefore, the positioning methods are different when processing, so the process can be divided according to different positioning methods;

(2) According to the rough and fine processing division process: according to the processing precision, stiffness and deformation of the Auto Industrial CNC Milling Aluminum parts, the process can be divided according to the principle of coarse and fine machining, that is, roughing and finishing, at this time Can be processed with different machine tools or different tools;

(3) According to the tool division process: In order to reduce the tool change time, compress the idle time and reduce the unnecessary positioning error, the parts can be processed according to the tool centralized process, that is, in one setup, use a tool as much as possible. Machining the parts that may be processed, and then replacing the other parts with another knife.

Delivery Message

FAQs

Q1: How does your company do regarding quality control?

A1: Our QC team will do strict quality control inspection before shipment to assure best quality.

Q2: What is the shipping cost?

A2: When we send the shipping cost to you, we always offer the cheapest and safest courier by comparing.

Q3: What's the delivery time?

A3: The delivery time for sample order is normally 1-5 working days after full payment received. For bulk order, it's about 10~15 working days after deposit received.

YOU MAY LIKE

_1744788508965.png)