Product Details

|

Product |

MJF 3D printing Parts |

|

Size |

Customized Size |

|

Material |

Black High Performance Nylon |

|

Finish |

Polishing, painting, Sandblasting ,surface marking etc. |

|

Application |

Industrial Parts, Auto Parts,Rapid prototypes etc. |

Introduction

MJF 3D printing Parts is a revolutionary 3D printing technology that primarily utilizes two separate thermal inkjet arrays to fabricate parts with remarkable precision and efficiency. During the printing process, one of the inkjet arrays sprays out a special flux material, while the other dispenses a finer agent. These substances work in tandem as energy is applied to the forming area, effectively melting the powder layer by layer. This intricate process is systematically repeated, gradually building up the object until the entire three - dimensional structure is complete. MJF stands out for its ability to process nylon materials, resulting in parts with enhanced mechanical properties such as superior strength, durability, and flexibility. Unlike some other 3D printing methods, MJF eliminates the need for time - consuming pre - heating and cooling phases. This significant advantage allows MJF to achieve much shorter processing cycles, enabling faster production turnaround times. As a result, MJF is not only a highly effective solution for producing high - quality components but also a time - and cost - efficient option for a wide range of manufacturing applications.

Advantage of MJF 3D printing

1. Wide range of printing materials

The high precision of molded products, wide range of materials and the characteristics of short production cycle make it popular in production and processing of industrial fields.

2. Machining complex geometries

3D printing technology breaks through tradition and realizes integrated design and manufacturing. Complex geometries can be built more easily without increasing cost.

3. Very suitable for functional parts and prototypes

3D printing technology can produce functional end-use parts on demand, thereby improving the progress of project.

4. Short production cycle, fast and cheap

Compared with traditional mold processing methods, 3D printing technology can be directly produced without mold , which saves time for mold creating and significantly improves production efficiency.

MJF 3D printing application

Due to the outstanding properties of the processed material, MJF 3D printing Parts has emerged as an ideal choice for creating prototypes and manufacturing small batches. The technology imparts exceptional strength, durability, and flexibility to the printed parts, making them suitable for initial design validation and low - volume production. However, MJF's capabilities extend far beyond prototyping. Its parts are now increasingly utilized in high - volume production across various industries. Thanks to its ability to produce components with high accuracy and remarkable performance, MJF can effortlessly bring intricate designs to life, printing parts with complex geometries that traditional manufacturing methods may struggle to achieve. This versatility and reliability have solidified MJF's position as a game - changing solution in modern manufacturing.

MJF 3D printing tips

Multi - Jet Fusion (MJF) represents an innovative and highly efficient machining approach that unlocks a plethora of opportunities for prototyping and small - batch production. It empowers designers with the freedom to make countless modifications to their designs, enabling them to explore various iterations and refine their concepts with ease. One of its notable advantages is the ability to hollow out thicker areas of a design. By doing so, not only can costs be significantly reduced through material savings, but it also effectively lightens the overall product weight without sacrificing its appearance or functionality. This makes MJF an attractive option for industries where weight reduction and cost - effectiveness are crucial factors. Nevertheless, it's important to exercise caution. When dealing with designs that have cavities, providing overflow holes for the uncured material inside is essential to ensure a smooth manufacturing process and a quality final product. It's worth emphasizing that because MJF constructs parts from powdered material, the resulting surface finish is typically rougher, and the resolution is lower compared to some alternative manufacturing processes. Designers must take this characteristic into account when conceptualizing intricate details or specific features, as it may impact the final aesthetic and performance of the product. Despite these considerations, MJF's unique capabilities continue to make it a valuable asset in the manufacturing landscape.

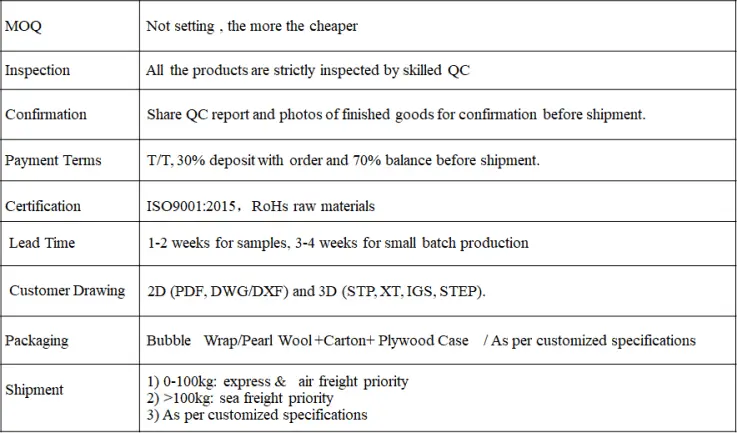

Delivery message

FAQ:

Q: What are the advantages of MJF 3D printing over traditional manufacturing?

A: MJF 3D printing offers design freedom, faster production times, and the ability to create complex geometries without tooling costs.

Q: How does MJF compare to other 3D printing technologies?

A: MJF provides better surface finish, higher accuracy, and more consistent mechanical properties compared to many other 3D printing methods.

Q: Can MJF 3D printing be used for large production runs?

A: Yes, MJF is well-suited for medium to high-volume production, offering consistent quality and cost-effectiveness at scale.

Q: What industries can benefit from MJF 3D printed parts?

A: MJF is ideal for automotive, aerospace, medical, consumer goods, and industrial manufacturing sectors.

Q: How can MJF 3D printing reduce my company's inventory costs?

A: By enabling on-demand production, MJF allows you to manufacture parts as needed, reducing the need for large inventories.

YOU MAY LIKE

_1744788508965.png)