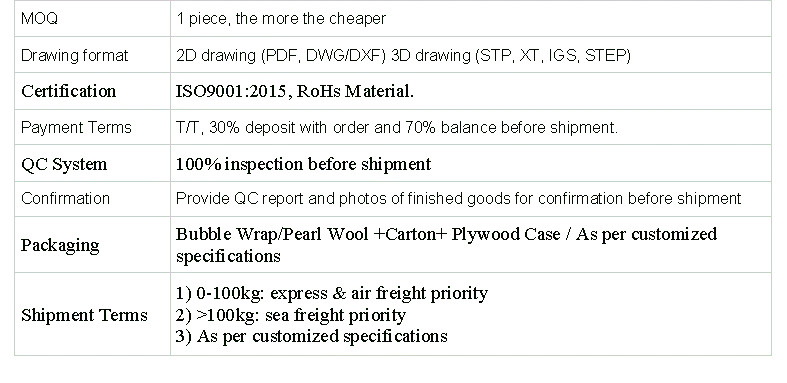

Product parameter

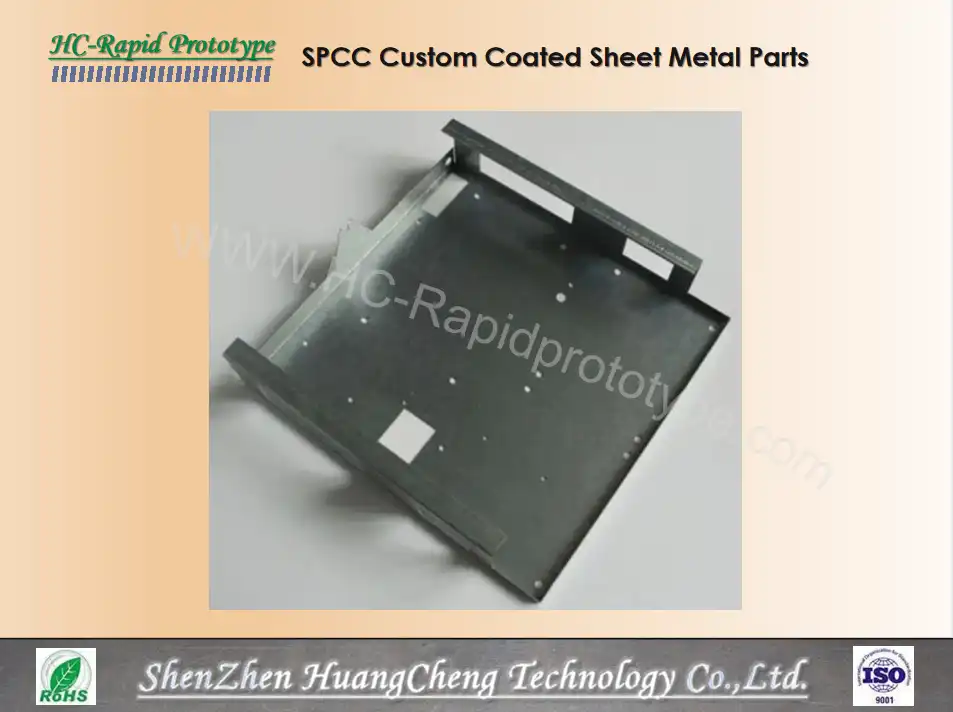

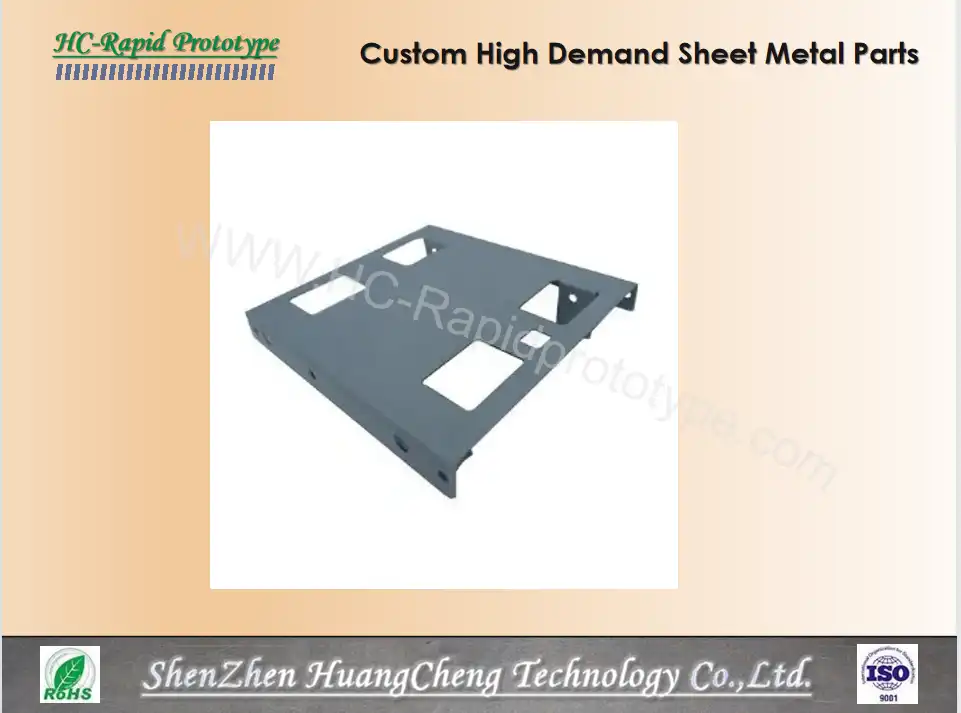

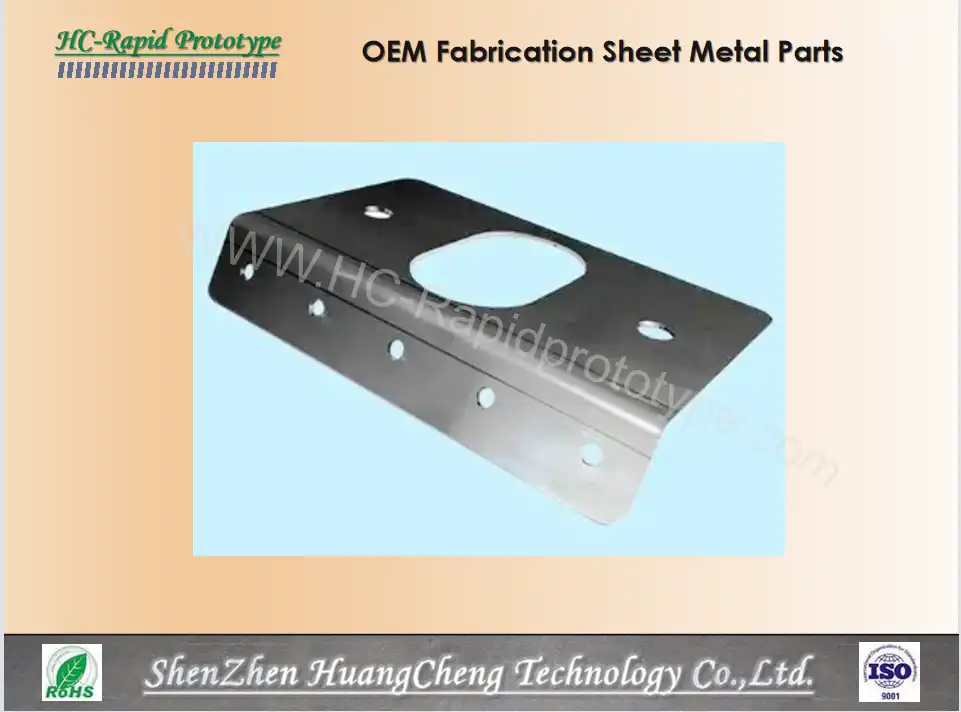

Product: Custom Aluminum Sheet Metal Parts

Material: 1-20mm thickness Aluminum sheet.

Finishing: Anodizing, Power coating, painting.

Processing Method: CNC laser cutting, bending, Shearing, welding.

Tolerance: ISO2768-m or defined in customer drawing.

Delivery time: 10-15 working days depending on the quantity.

Introduction

HC-Rapid Prototype has been a dedicated OEM factory for over a decade, specializing in producing a wide range of high-quality products. Our team of highly skilled technicians boasts extensive experience in Sheet Metal Parts Fabrication, enabling us to handle diverse projects with precision and expertise. We are proficient in processing various Fabricated Metal Products, including cabinets, brackets, chassis, and enclosures, among others. For aluminum sheet metal parts, we offer an array of surface treatment options, such as colorful anodizing, power coating, painting, polishing, silk screening, and other surface marking techniques. With a commitment to excellence, we look forward to receiving your Request for Quotation and establishing a long - term, mutually beneficial cooperation.

Aluminum plate properties

Aluminum sheet is significantly lighter than steel, and in addition to being light, aluminum sheet metal provides a high level of corrosion protection. It is usually used in scenarios that require moisture protection, such as the production of ships. It's important to note, though, that aluminum sheets can also corrode, but offer better corrosion resistance than most other types of metals.

Aluminum sheets have the following grades

1100-H14 Aluminum

3003-H14 Aluminum

5052-H32 Aluminum

6061-T6 Aluminum

More Custom Aluminum Sheet Metal Parts for Reference

Our advantages and service

Comparing to other manufacturer , we can offer the following:

- Competitive Price: We leverage efficient production processes and strong supplier relationships to offer cost - effective solutions. Our pricing strategy ensures you get high - value products without breaking the bank, remaining highly competitive in the market.

- Good Service: Our dedicated team is committed to providing top - notch customer service. From prompt responses to inquiries to after - sales support, we prioritize your satisfaction at every stage of our business interaction.

- Rich Experience: With years in the industry, we have amassed extensive knowledge and expertise. This experience allows us to handle diverse projects with confidence, delivering reliable results tailored to your specific needs.

- Perfect Quality: Stringent quality control measures are integrated into our operations. Every product undergoes thorough inspection to meet the highest standards, ensuring flawless performance and durability for your peace of mind.

Why Choose ShenZhenHuangCheng Technology?

- Experienced team of engineers and technicians: Our group comprises seasoned professionals with years of hands - on knowledge. They bring innovative solutions and in - depth technical know - how to every project, ensuring seamless execution and outstanding results.

- Advanced manufacturing capabilities: Equipped with state - of - the - art machinery and cutting - edge technology, we can handle complex tasks with precision. Our facilities enable us to produce high - quality products efficiently, meeting the most demanding requirements.

- Commitment to quality and customer satisfaction: Quality is at the core of everything we do. We adhere to strict standards and conduct thorough inspections to guarantee top - notch products. Our focus on customer needs ensures a satisfying experience throughout the process.

- Competitive pricing and value - added services: By optimizing our processes, we offer cost - effective solutions without sacrificing quality. Alongside competitive prices, we provide value - added services such as after - sales support and customization options to enhance your overall experience.

Delivery terms

FAQs:

Q: What is the minimum order quantity for Custom Aluminum Sheet Metal Parts?

A: We offer flexible production volumes to accommodate your needs, from small prototype runs to large-scale orders.

Q: Can you assist with design optimization for cost-effectiveness?

A: Absolutely! Our engineering team can review your designs and suggest modifications to improve manufacturability and reduce costs.

Q: What is the typical lead time for custom parts?

A: Lead times vary based on complexity and quantity, but we pride ourselves on quick turnarounds. Contact us for a specific quote.

Q: Do you offer any value-added services?

A: Yes, we provide design assistance, prototyping, assembly, and inventory management solutions to streamline your supply chain.

Q: How do you ensure consistent quality across large orders?

A: We implement rigorous quality control measures throughout the production process, including regular inspections and advanced testing equipment.

YOU MAY LIKE

_1744788508965.png)