Product Details

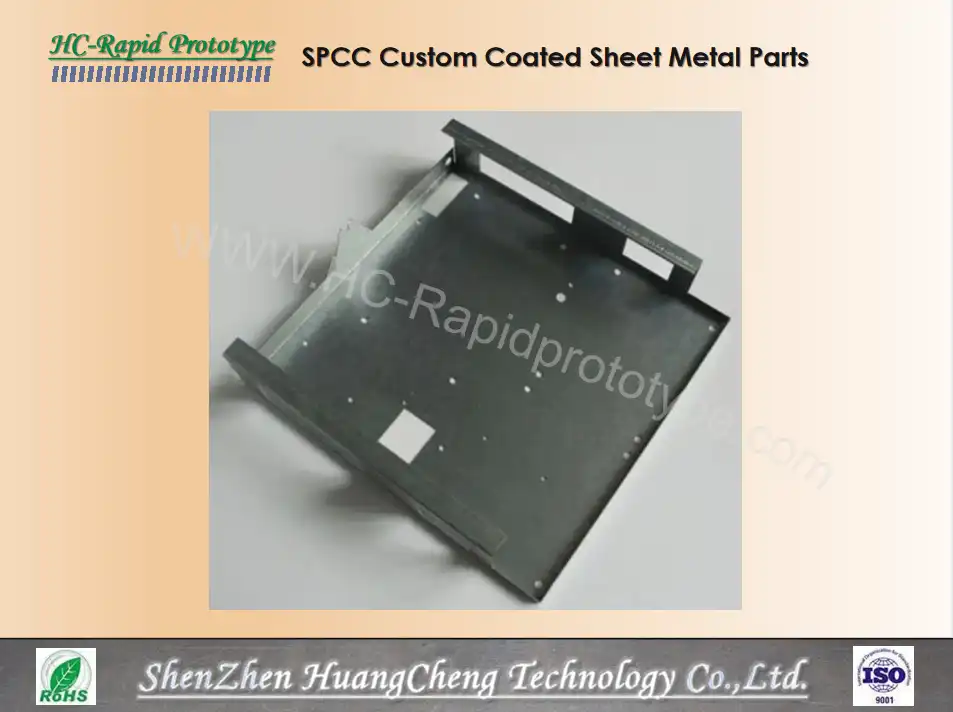

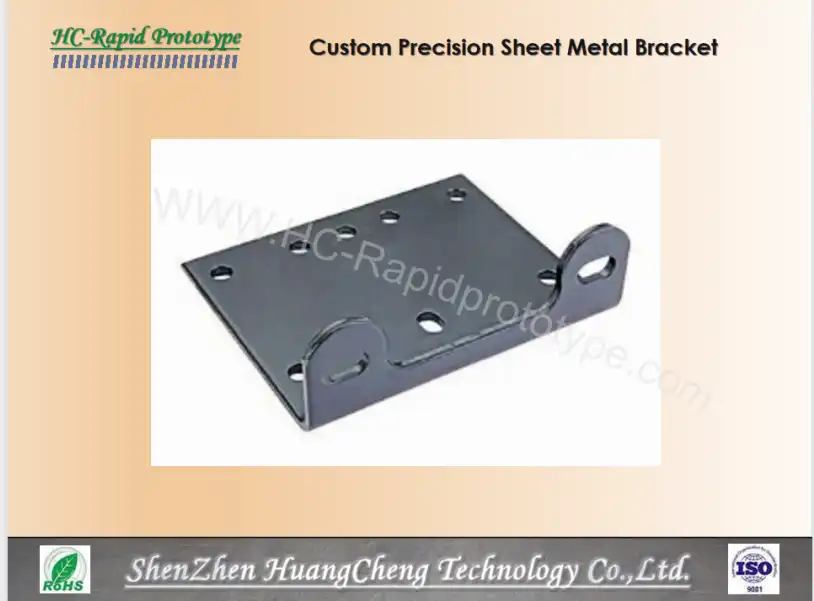

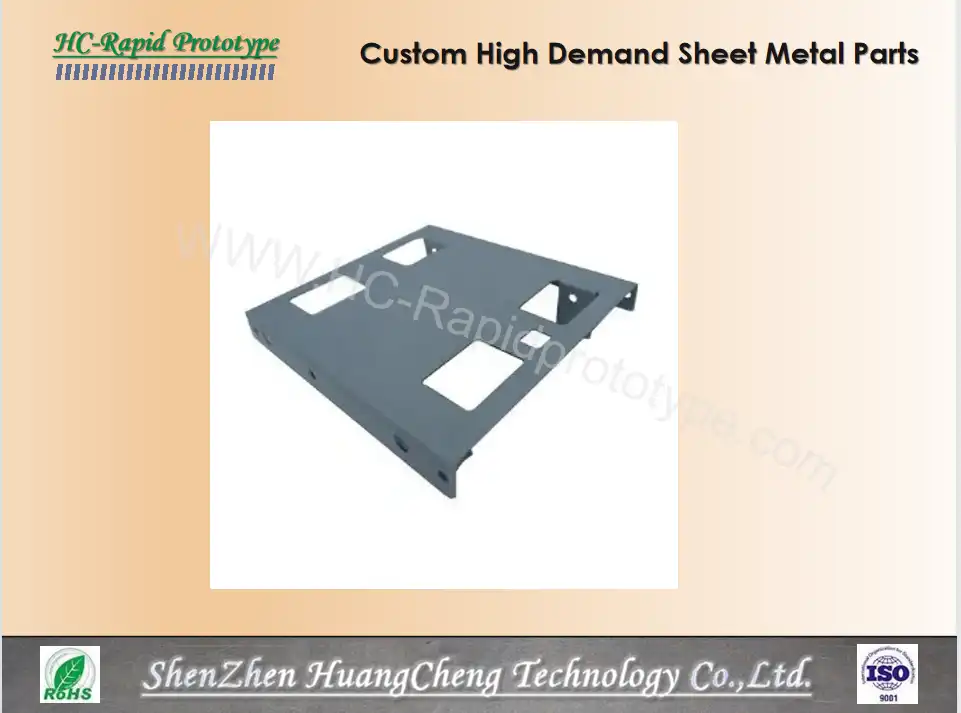

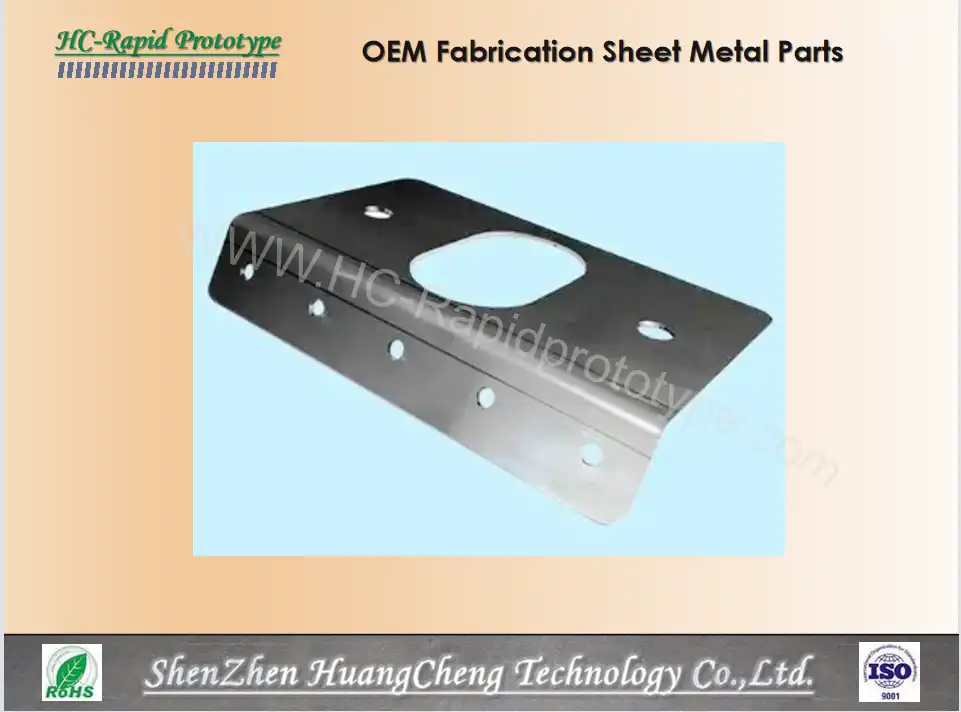

Product: Custom Stainless Steel Sheet Metal Parts

Material: 1-20mm thickness Stainless steel sheet

Finishing: Sand blasting, polished.

Processing Method: laser cutting, bending, shearing, welding, finishing.

Application Industry: hardware housing , cabinet and others products.

Tolerance: ISO2768-m or according to clients' drawing request.

Delivery time: 5-12 working days for prototypes

Introduction

Most steel plates are stainless steel, which contains chromium to prevent corrosion. Steel sheets are ductile and can be deformed and subjected to other machining operations with relative ease. Stainless steel is the most common type of sheet metal, the majority of sheet metal produced worldwide is composed of stainless steel, and due to its unparalleled popularity, stainless steel plate has become almost synonymous with sheet metal. Custom Stainless Steel Sheet Metal Parts include the following grades:

304 stainless steel

316 stainless steel

410 stainless steel

430 stainless steel

Advantage and Service

We specialize in the production of Custom Stainless Steel Sheet Metal Parts, which are predominantly applied in hardware housing, cabinets, and ATM machines. The material used is mainly high - quality stainless steel sheet, offering excellent corrosion resistance, durability, and aesthetic appeal. With advanced manufacturing capabilities, the maximum thickness we can bend reaches an impressive 20mm, enabling us to meet a wide range of customer requirements for different projects. At HC, we are fully committed to producing high - quality fabricated metal products. Our comprehensive services cover every stage of the manufacturing process, including precise laser cutting for accurate shapes, expert bending to form the desired structures, efficient shearing for clean edges, reliable welding to ensure structural integrity, and professional finishing to enhance the appearance and functionality. Each step is carried out by our skilled technicians using state - of - the - art equipment and strict quality control measures. We understand the importance of customized solutions in the market, and we strive to tailor our products to your specific needs. Whether it's a small - scale project or a large - volume order, we have the resources and expertise to deliver outstanding results. We look forward to receiving your Request for Quotation (RFQ) and establishing a long - term and mutually beneficial cooperation with you.

Product Characteristics:

- Excellent corrosion resistance: Our products are engineered to offer outstanding protection against rust and chemical degradation. Whether exposed to moisture, harsh chemicals, or extreme weather, they maintain their integrity, reducing maintenance and replacement costs over time.

- High strength-to-weight ratio: Combining remarkable strength with low weight, these materials provide optimal performance in various applications. They enable the creation of lightweight yet robust structures, enhancing efficiency and reducing energy consumption in transportation and construction.

- Superior formability and weldability: With excellent formability, our materials can be easily shaped into complex designs without cracking or distortion. Their high weldability ensures strong, reliable joints, allowing for seamless integration in manufacturing processes and facilitating the production of intricate components.

- Aesthetic appeal for visible applications: Featuring a sleek and polished surface, our products add an elegant touch to visible applications. The consistent finish and attractive appearance make them ideal for use in consumer goods, architectural elements, and other projects where visual appeal is essential.

Production Process:

1. Design consultation and optimization

2. CNC precision cutting and forming

3. Welding and assembly (if required)

4. Quality control inspection

5. Surface finishing and treatment

6. Packaging and shipping

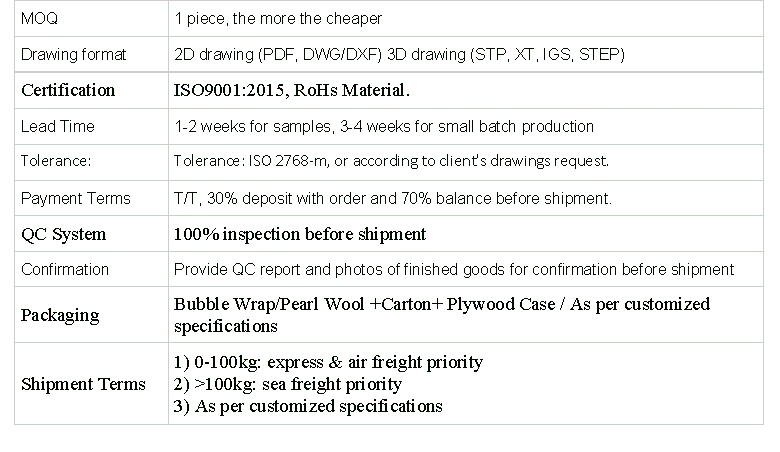

Delivery

FAQs

Q. How long will our price be valid?

A: We are a friendly and professional supplier, never greedy on windfall profit. Basically, our price remains valid for 60 days. Customers can negotiate with our team on the valid term. We only adjust our price based on two situations:

a) The rate of USD: RMB varies significantly according to the international currency exchange rates.

b) The original material fee varies, for example, the Stainless Steel/Aluminum/Copper.

YOU MAY LIKE

_1744788508965.png)