Product Details

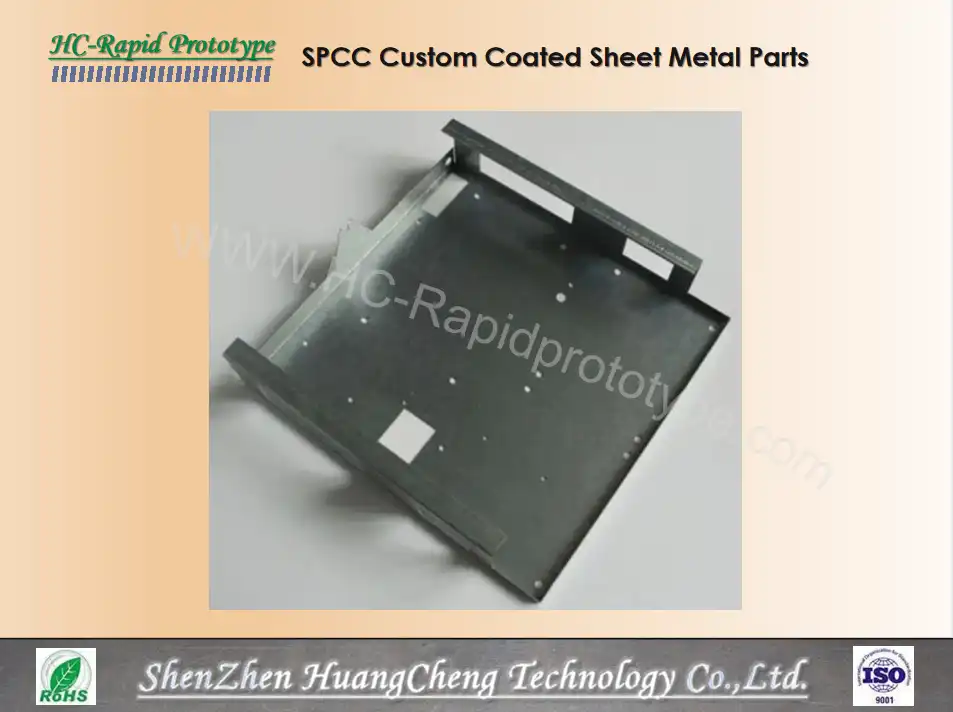

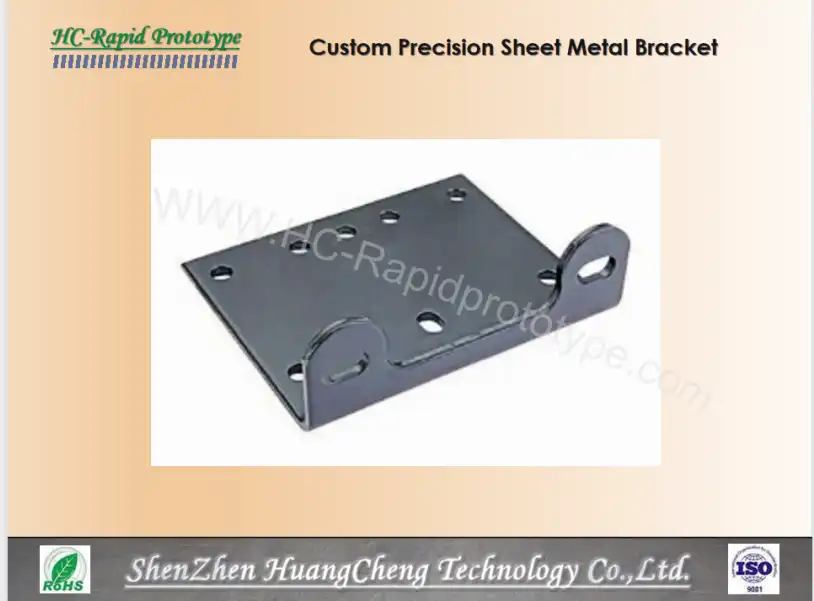

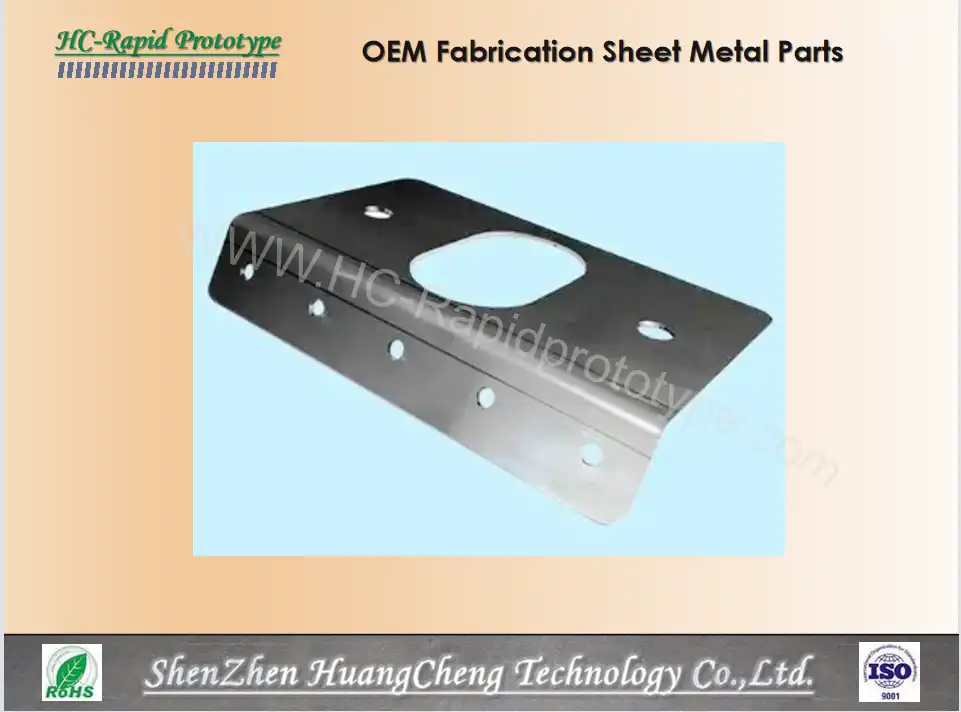

Name: Custom Brass Sheet Metal Fabrication Parts

Material: Brass, copper etc.

Surface Treatment: Power coating, painting, Zinc-plated.

Processing Method: Shearing, laser cutting, welding, bending etc.

Application Industry: Connector, Plug, Socket, Motion Control, Power Generation, Temperature Control.

Tolerance: ISO2768-m / Defined by customer / Refer to provided drawing

Delivery time: For prototypes 5-10 working days; For Small batch production 2-3 weeks.

Introduction

Brass is essentially an alloy of copper and a small amount of zinc that is strong, corrosion-resistant and has excellent electrical conductivity. Due to its conductive properties, brass sheet metal can be used in electrical applications where steel and aluminum are poor choices. Steel, aluminum and brass sheet metal are all relatively strong and offer a high level of corrosion protection. Among them, steel is the strongest, aluminum is the lightest, and brass is the most conductive of the three metals.

HC-Rapidprototype Advantage and Service:

At HC-Rapidprototype, we pride ourselves on our ability to provide:

- Rapid prototyping and production capabilities: Our advanced 3D printing and CNC machining technologies enable us to quickly transform your design concepts into physical prototypes. Once approved, we seamlessly transition to full - scale production, ensuring a fast turnaround from idea to finished product.

- Flexible manufacturing processes to accommodate various order sizes: Whether you need a small - batch custom order or a large - scale production run, our adaptable manufacturing setup can handle it all. We adjust our processes and resources efficiently to meet your specific volume requirements with consistent quality.

- Comprehensive quality control measures: From raw material inspection to final product testing, our multi - stage quality control system leaves no room for error. We use state - of - the - art testing equipment and strict inspection protocols to guarantee that every product meets the highest standards.

- On - time delivery and responsive customer support: We understand the importance of timely delivery. Our logistics team works closely with reliable carriers to ensure your orders arrive on schedule. Meanwhile, our dedicated customer support team is always ready to address any inquiries or concerns promptly.

Product Characteristics:

Our Custom Brass Sheet Metal Fabrication Parts offer:

- Excellent corrosion resistance: Our materials are designed to offer outstanding protection against rust and chemical deterioration. They can withstand exposure to moisture, saltwater, and harsh chemicals, ensuring long - term durability and minimal maintenance in various environments.

- High electrical and thermal conductivity: With exceptional electrical and thermal conductivity properties, these materials enable efficient transmission of electricity and heat. They are ideal for applications requiring rapid heat dissipation or reliable electrical connections, enhancing overall performance.

- Superior machinability and formability: Our products feature excellent machinability and formability, allowing for easy shaping, cutting, and bending. This makes them highly suitable for manufacturing complex components with precision, reducing production time and costs.

- Aesthetic appeal for visible components: Boasting an attractive appearance, these materials add a touch of elegance to visible components. Their smooth surface finish and consistent color make them perfect for applications where both functionality and visual appeal are crucial.

Why Choose HC-Rapidprototype?

- Extensive experience in custom fabrication

- Cutting-edge technology and equipment

- Competitive pricing without compromising quality

- Dedicated support throughout the project lifecycle

Comment

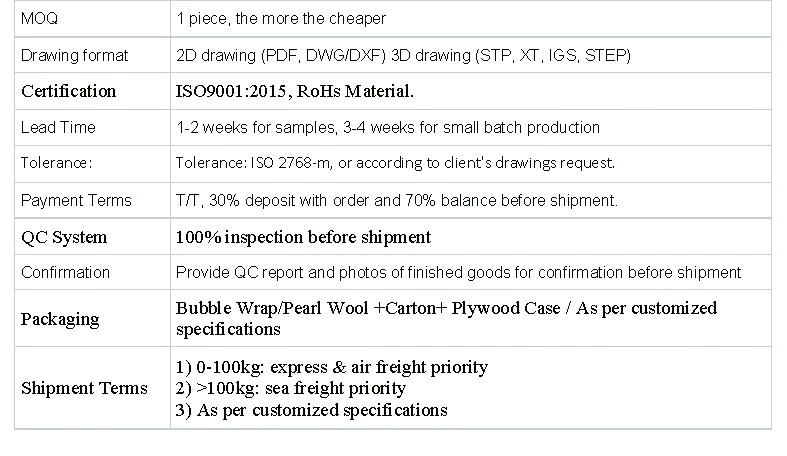

Our company has passed ISO9001 system certification. All quality control links are strictly checked from raw materials to process inspections to shipment delivery are supervised by professionals.

Delivery terms

FAQs

Q: What material HC can do for sheet metal fabrication?

A: Cold rolled steel, A3,Q235, galvanized steel sheet, SECC

Stainless steel, aluminum, brass, copper.

Q2: What projects HC already done ?

A2: HC has rich experience on medical cabinet, electronic enclosure, bracket, clamp, box etc.

YOU MAY LIKE

_1744788508965.png)