Product Details

|

Product |

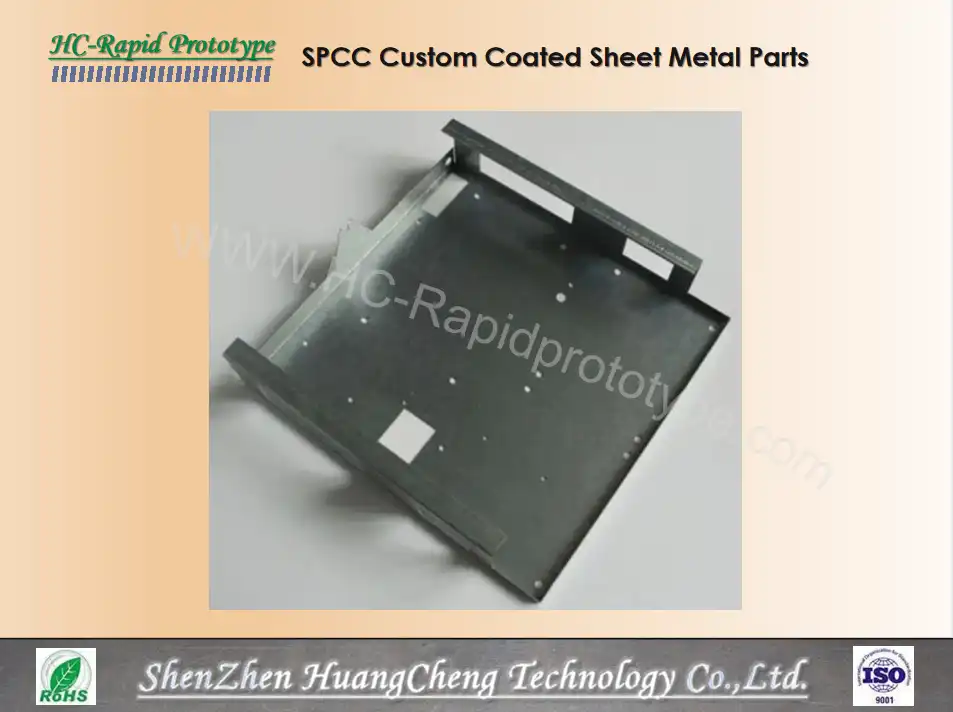

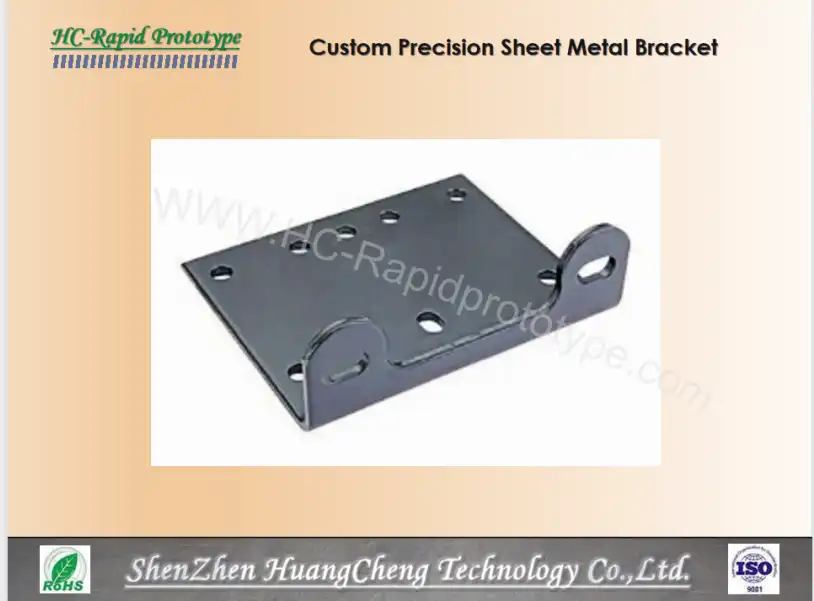

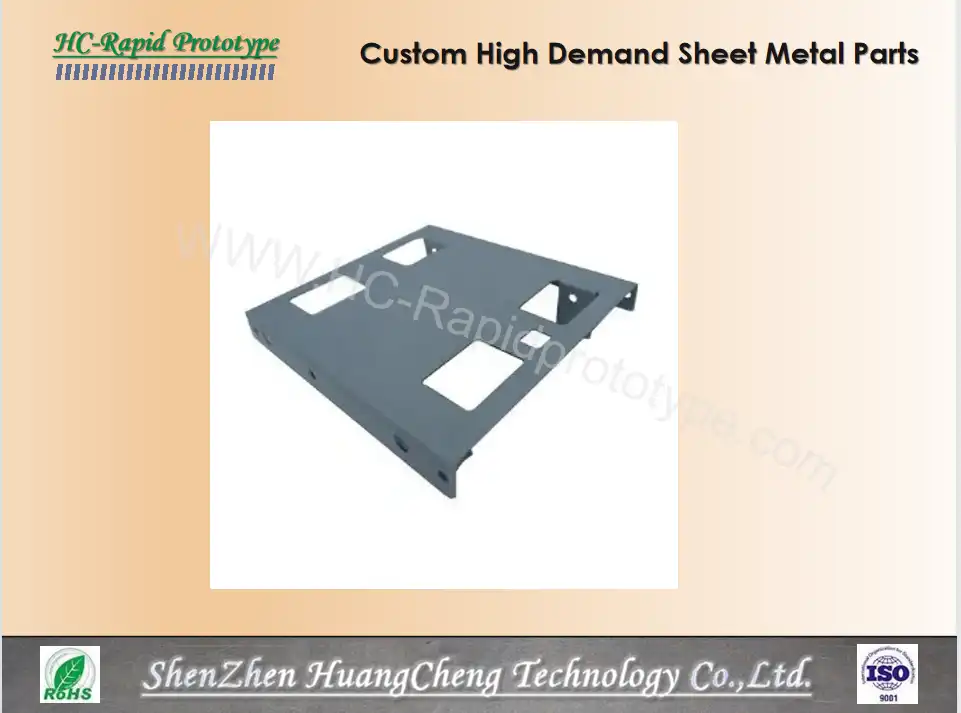

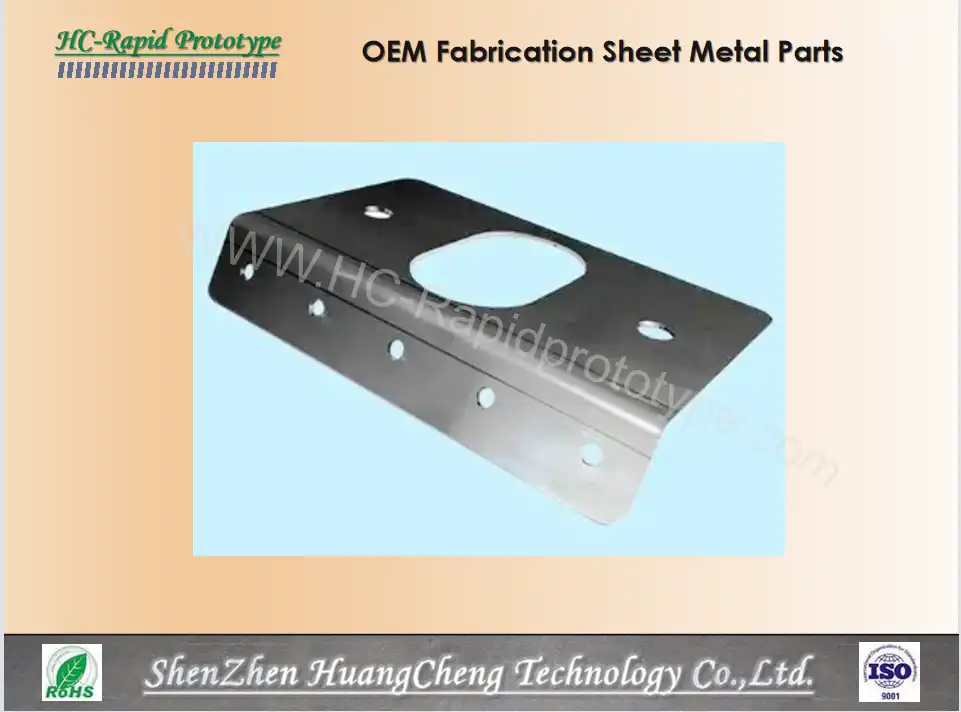

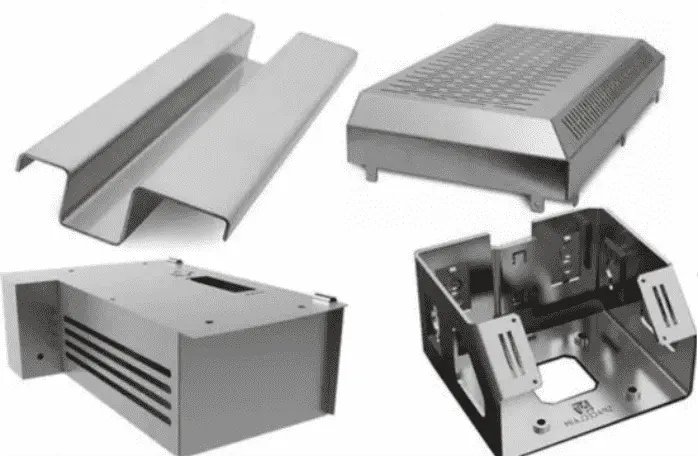

Custom Sheet Metal Enclosure Fabrication |

|

Material |

Copper, Stainless Steel, Carbon Steel, Cold Roll Steel, Hot Roll Steel, Zinc Plate, Aluminum, Custom Alloy, Aluminum Alloy And Other Sheet Metal. |

|

Finishing |

Polishing, Zinc plating, Nickel plating, Chrome plating, Powder Coating, Anodizing, Sandblasting, Spray Coating, Electroplating, Mirror Polish, Brushing or Customized. |

|

Size |

Length 10~10000mm Thickness 1~100mm |

|

Machining Precision |

As customer's drawing requested |

Custom Sheet Metal Enclosure Fabrication , please review.

Product feature and application

Sheet Metal Enclosure Fabrication Parts are the result of an intricate and comprehensive cold working process. Typically with a thickness of less than 6mm, each individual part maintains uniform thickness throughout, ensuring consistency and reliability. Our company primarily specializes in sheet metal fabrication services, covering a wide range of processes including welding, precise laser cutting, and expert bending of both sheet and tube materials. We tailor our manufacturing of sheet metal components to specific industries, effectively eliminating losses stemming from poor logistics coordination. This meticulous approach guarantees that components and modules are completed successfully and delivered on schedule. Our seasoned technical team, with years of hands - on experience, is a key strength. Additionally, we offer a diverse array of surface treatments such as painting for aesthetic appeal, powder coating for enhanced durability, galvanizing for corrosion resistance, chrome plating for a sleek finish, anodizing for added protection, and mirror polishing for a high - end look. For complex structural components, entrust your project to us. Our sheet metal experts will not only support your project but also recommend the optimal custom solution tailored to your unique requirements.

Production Process:

- Our design consultation and optimization service offers expert advice, refining your concepts to ensure functionality and efficiency.

- CNC cutting and forming utilize advanced technology for precise shaping, delivering accurate and high - quality parts.

- Welding and assembly are carried out by skilled technicians, joining components firmly for a robust final product.

- Surface treatment and finishing provide various options like coating and polishing, enhancing appearance and durability.

- Quality inspection and testing rigorously verify each part, ensuring compliance with high - standard specifications.

- Packaging and shipping safeguard products, ensuring safe and timely delivery to your desired destination.

Our advantages

- As a direct rapid prototyping manufacturer, we streamline the process, offering quick turnarounds and direct communication for efficient production.

- Our very professional technical team, with extensive expertise, drives innovation and ensures top - notch quality in every project we undertake.

- Leveraging abundant localized resources, we maintain high - quality standards while delivering cost - effective products to meet diverse needs.

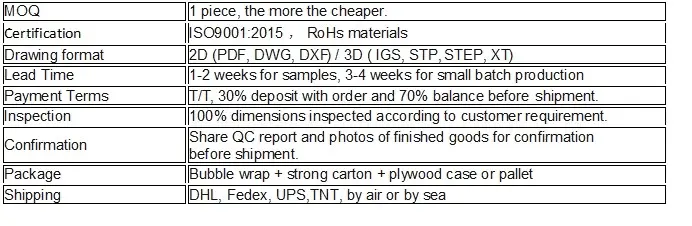

Delivery

Why Choose ShenZhenHuangCheng Technology Co.,Ltd?

- Expertise in complex designs and tight tolerances

- Quick turnaround times to meet your production schedules

- Cost-effective solutions without compromising on quality

- Comprehensive services from design to delivery

- Long-term partnership potential with a financially stable supplier

FAQ

Q: Can you manufacture complex sheet metal parts?

A: Yes , We can manufacture high-quality scratch-free sheet metal parts with complex contours according to International Standards (ISO). We process all conventional types of sheet metal, such as sheet steel, zinc, aluminum or copper, from a minimum thickness of 1 mm to a maximum of 100 mm.

Q: What is the minimum order quantity for custom sheet metal enclosures?

A: We offer flexible order quantities to accommodate your needs, whether it's a small prototype run or large-scale production.

Q: Can you assist with the design process?

A: Absolutely! Our team of experts can provide design assistance and prototyping services to ensure your enclosure meets all specifications.

Q: How do you ensure consistent quality across large production runs?

A: We employ advanced CNC machinery and rigorous quality control measures throughout the production process to maintain high standards of precision and consistency.

Q: What industries do you typically serve?

A: While we specialize in electronics, telecommunications, automotive, and industrial equipment, our custom sheet metal enclosure fabrication services cater to a wide range of industries.

YOU MAY LIKE

_1744788508965.png)