Product Parameter

|

Product |

Custom CNC Sheet Metal Parts |

|

Material |

Aluminum, bronze, stainless steel, steel, alloy, copper, plastic etc. |

|

Surface Finish |

Hot galvanized, Polish, Anodize, Sand blasting, Powder coating, Vacuum Plating, Nickel, Zinc, Chrome, Silver plating, gold-plated, imitation gold-plated, etc. |

|

Thickness |

0.5mm~6mm, or other special available |

|

Application

|

Electric power, electronic appliances, elevators, automobiles, commercial household appliances and other industries. |

Introduction

Custom CNC Sheet Metal Parts represents a sophisticated approach that involves utilizing CNC equipment for all or the majority of manufacturing processes. Key tools in this arsenal include high - tech CNC machines, precise CNC laser cutting machines, and versatile CNC bending machines. By leveraging advanced CNC technology, sheet metal can be processed with remarkable precision. The computer - controlled systems enable the execution of intricate designs and complex geometries with micron - level accuracy, resulting in superior processing effects and high - quality products. This method ensures high product accuracy, eliminating human errors and reducing the need for rework. As a result, it significantly reduces development time, allowing for seamless paperless manufacturing that directly transforms digital design drawings into finished products. Moreover, CNC sheet metal is ideally suited for flexible production. Its modular and adaptable nature allows for efficient accommodation of small batches and diverse product varieties with ease, making it a cost - effective and time - saving solution for industries ranging from automotive and aerospace to consumer electronics and architecture.

The characteristics of CNC sheet metal processing are:

- It is simple and convenient to use. For some workpieces with complex shapes or workpieces with relatively thin thickness, it can be automatically processed. Moreover, its low input cost can help to improve economic efficiency. Featuring an intuitive and user - friendly graphical interface, along with intelligent automated programming algorithms, it streamlines the operation process, making it accessible even for those with limited technical expertise. This enables the automatic processing of workpieces with complex geometries or thin - walled structures that require precision handling. With a minimal upfront investment, it not only boosts production output but also reduces operational costs through optimized resource utilization, significantly enhancing overall productivity and profitability, and thus improving economic efficiency.

- The quality of the finished product is very good, because of its good flatness and high precision, so that the product can have good consistency. Incorporating state - of - the - art calibration technologies and advanced precision - control mechanisms, it ensures exceptional flatness and pinpoint accuracy in every production cycle. These systems continuously monitor and adjust the manufacturing process to maintain strict quality standards. This meticulous approach to quality control results in uniformly high - quality finished products, ensuring consistent performance and reliability across the entire production run, meeting and exceeding customer expectations for product quality.

- Since it can realize small batch production and the production speed is fast, so the efficiency can be improved. Its highly adaptable and modular design allows for quick and seamless reconfiguration between different small - batch manufacturing tasks, minimizing downtime. Paired with high - speed processing capabilities that utilize advanced materials - handling techniques and optimized machining strategies, it can rapidly process materials while maintaining strict quality requirements. This combination enables it to maximize output within tight time frames, significantly enhancing overall production efficiency and making it an ideal solution for industries with diverse and frequently changing production demands.

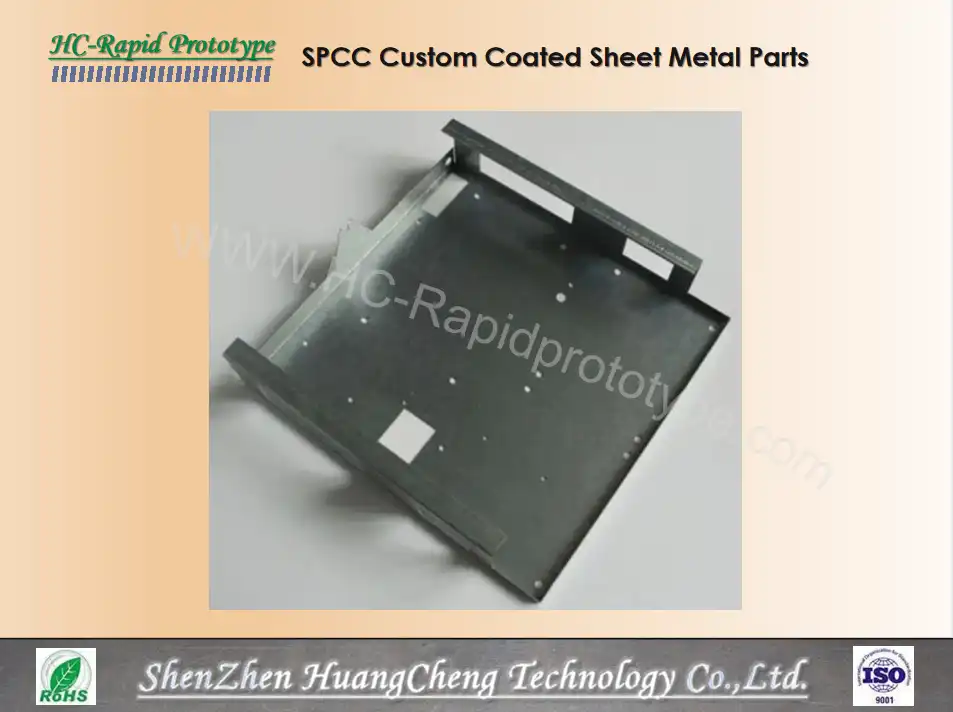

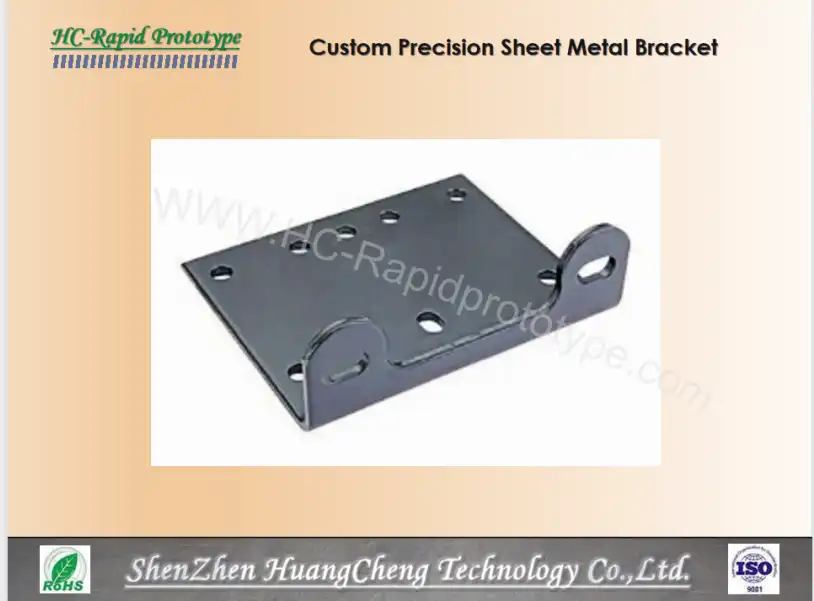

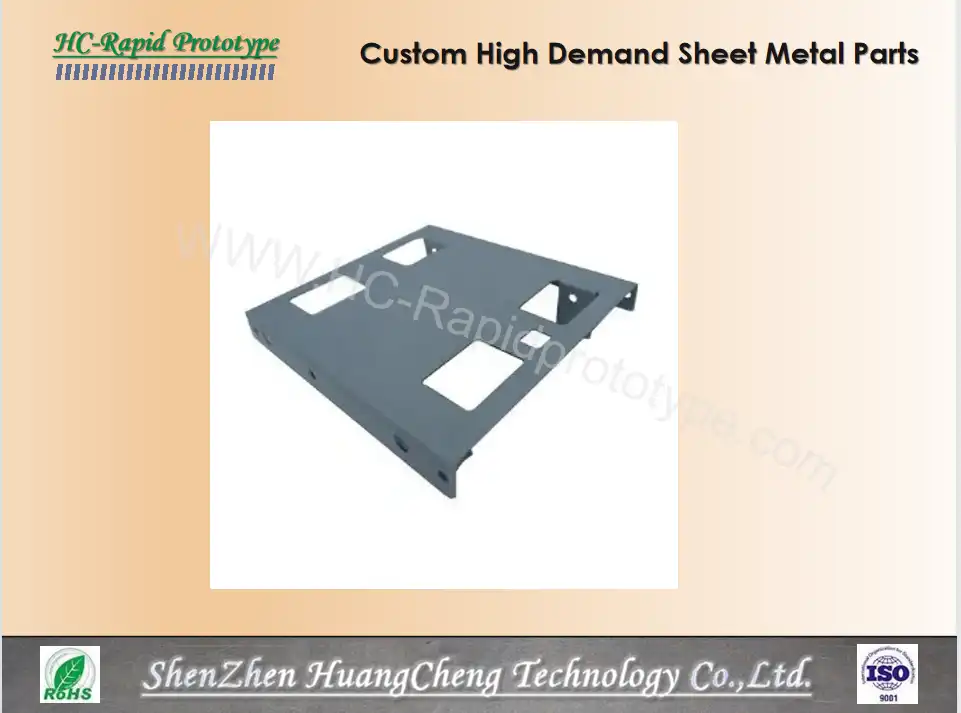

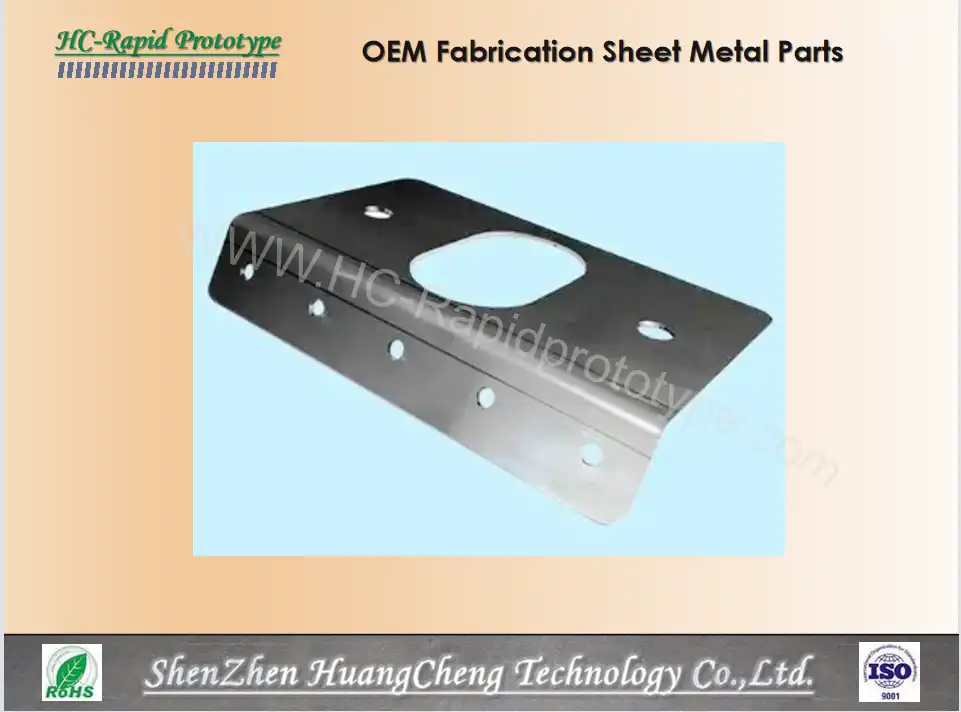

*Some Custom CNC Sheet Metal Parts for Reference

Delivery and Service

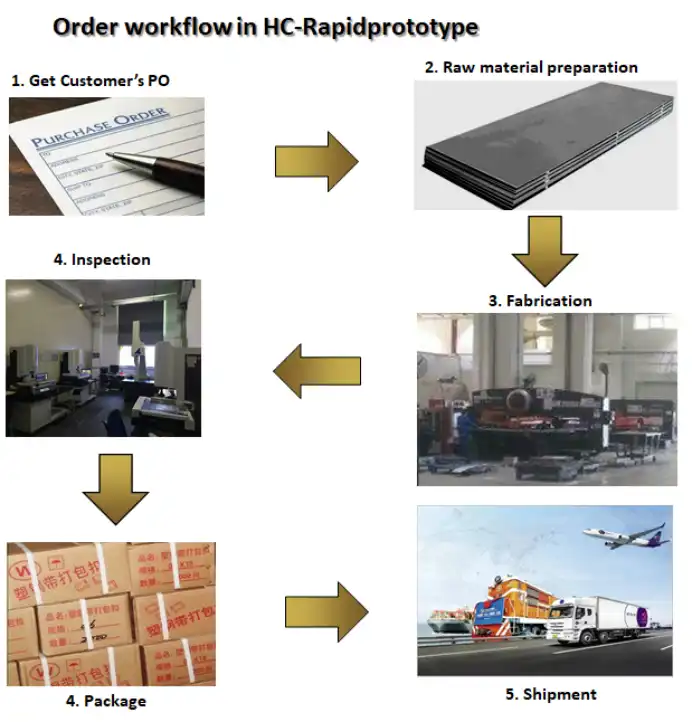

HC Workflow

FAQs

Q1: ls your organization committed to the concept of total quality management?

A1: Yes, no matter in laser cutting, bending, or CNC machining, the workers will conduct the first sample inspection and random inspection during the processing to ensure the quality of the products.

Q2: How many checks are performed on a project?

A2: Usually, products will go through the following four inspections: incoming inspection, production first inspection, sampling inspection, and pre-shipment inspection. Among them, sampling inspection will be conducted multiple times.

YOU MAY LIKE

_1744788508965.png)