Product Details

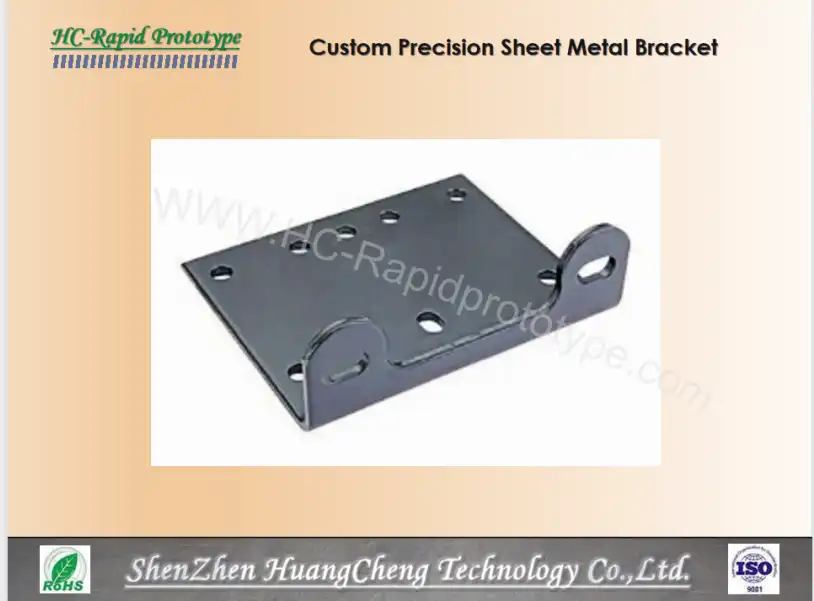

Name: Custom Precision Sheet Metal Bracket

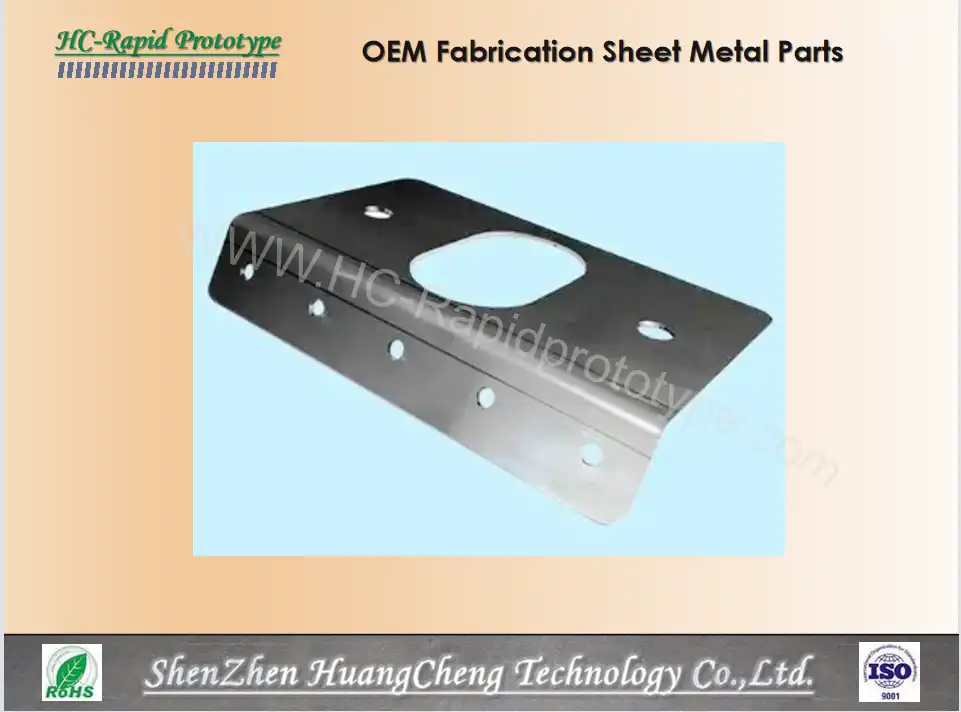

Material: Cold rolled steel, Galvanized steel , Carbon steel.

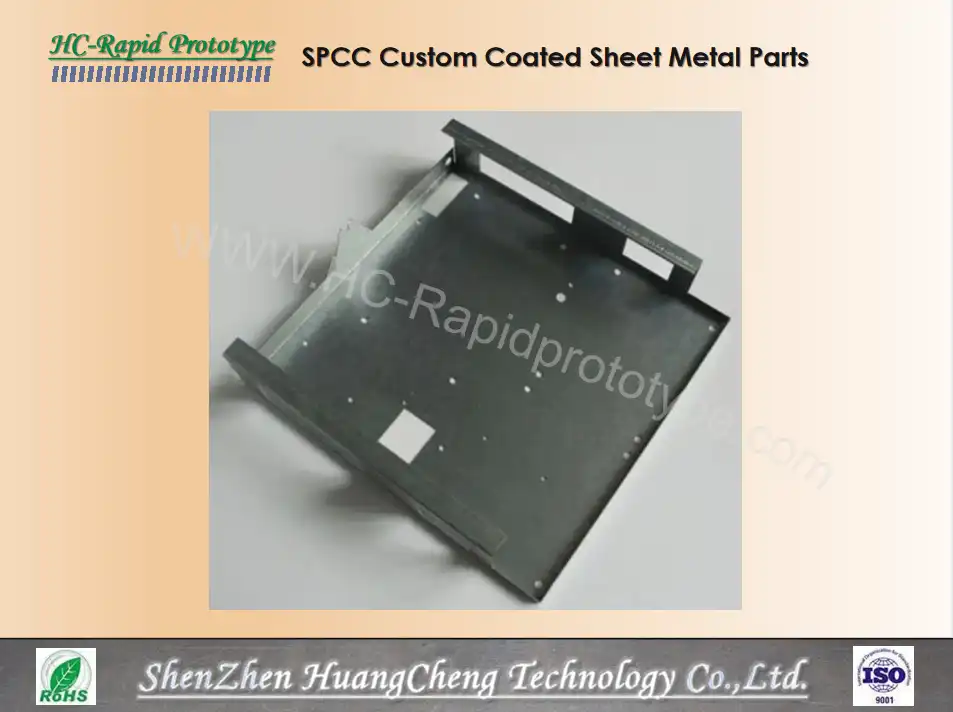

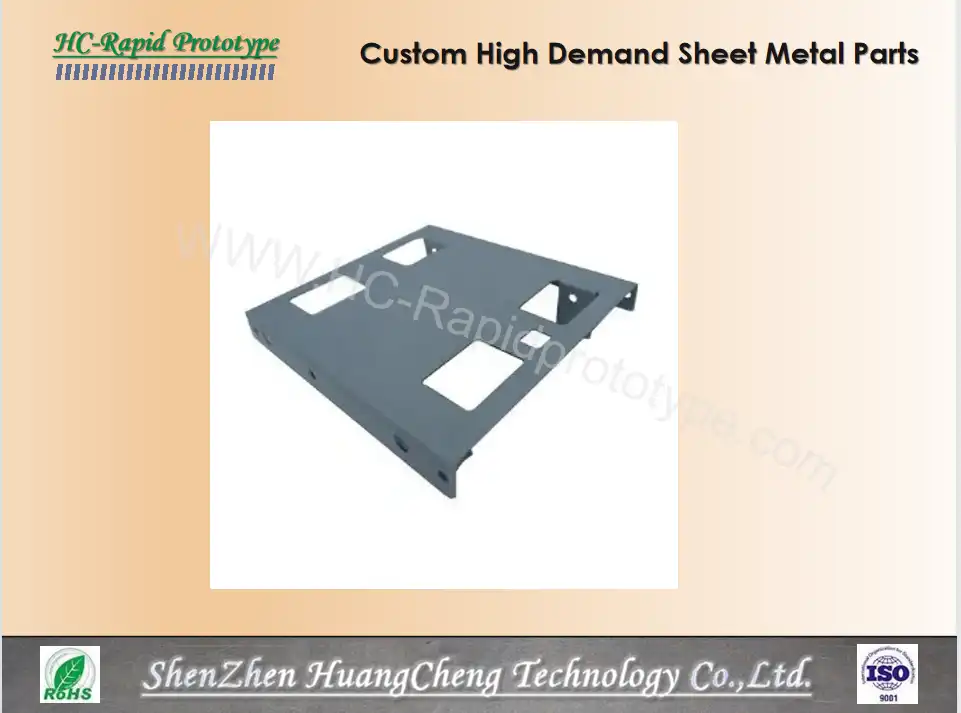

Surface finish: Power coating, painting, Zinc-plated.

Processing Method: Shearing, bending, laser cutting, welding

Application Industry: Machine Control, Motion Control, Power Generation, Temperature Control etc.

Tolerance: ISO2768-m or customized

Delivery time: 5-15 working days. Depending on the quantity.

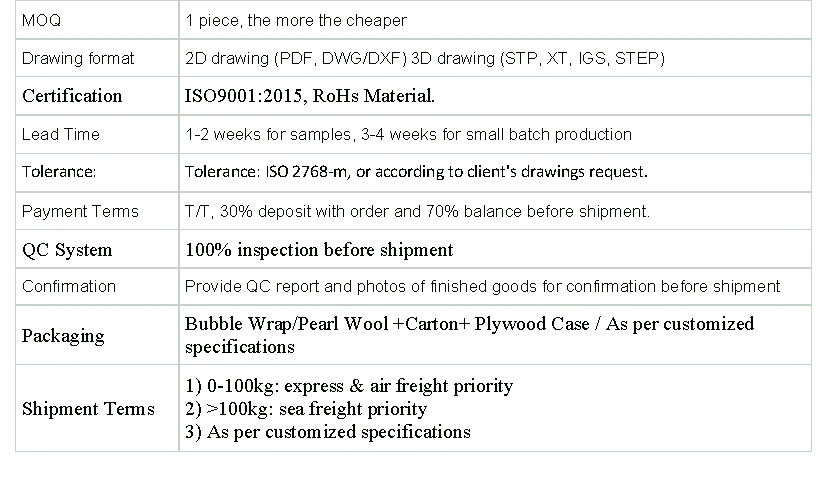

Delivery & Service

Introduction

A bracket serves as a crucial intermediate component, primarily used to firmly secure one object, like a shelf, to another. It achieves this connection by utilizing actual fasteners such as screws, which attach the bracket to the relevant parts, ensuring a stable and reliable link. This functionality makes brackets indispensable in various industries, from furniture assembly to construction and machinery manufacturing. Beyond just creating a connection between two elements, a bracket also plays a vital role in providing support. For instance, gusset brackets are ingeniously designed with a diagonal cross-section. This unique structure significantly reduces the strain on the bracket, distributing the load more evenly and allowing it to bear heavier loads with ease. This makes gusset brackets ideal for applications where strength and durability are paramount. When it comes to manufacturing brackets, especially simple ones like corner brackets, sheet metal fabrication stands out as one of the easiest and most cost-effective methods. Custom Precision Sheet Metal Bracket's malleability allows for precise shaping through processes like cutting, bending, and punching. Typically, a bracket comprises two or more flat surfaces joined along an edge. The most straightforward approach to fabricating such an item is often to bend a flat piece of material, like metal, at multiple points. A simple illustration is taking a flat rectangle with a straight profile and adding a 90° bend, transforming it into an L-shaped bracket. This basic yet effective design can be further customized with additional holes, slots, or folds to meet specific mounting and load-bearing requirements.

Our Advantage

- As the original manufacturer, we cut out middlemen markups, passing on significant savings. Our competitive prices ensure you get top - quality products without breaking the bank.

- Our professional QC team rigorously inspects every product, while the R&D team innovates constantly. Together, they guarantee that each item meets the highest quality standards.

- We understand the urgency of getting rapid prototypes. With our efficient processes, we offer a short lead time, helping you quickly move from concept to a tangible model.

- Equipped with advanced measurement equipment, we achieve pinpoint accuracy in production. This enables us to create products that meet even the most exacting specifications.

- Whether you need a large batch or a small quantity, we welcome your orders. Our flexible production setup allows us to cater to diverse customer needs.

- For OEM works, we can precisely transform your drawings, samples, or ideas into reality. Our experienced team ensures that the final product aligns perfectly with your requirements.

Applications:

- Industrial equipment mounting involves securely positioning heavy machinery and systems, ensuring stability and vibration - dampening to optimize performance and prolong equipment lifespan.

- Automotive component support focuses on fabricating brackets and fixtures that hold various parts in place, enhancing vehicle safety, durability, and overall operational efficiency.

- Aerospace structural elements are precision - engineered components designed to withstand extreme conditions, providing essential support for aircraft frames and ensuring flight integrity.

- Electronics housing and support creates protective enclosures and internal structures that safeguard delicate electronic components from external damage while facilitating proper heat dissipation and connectivity.

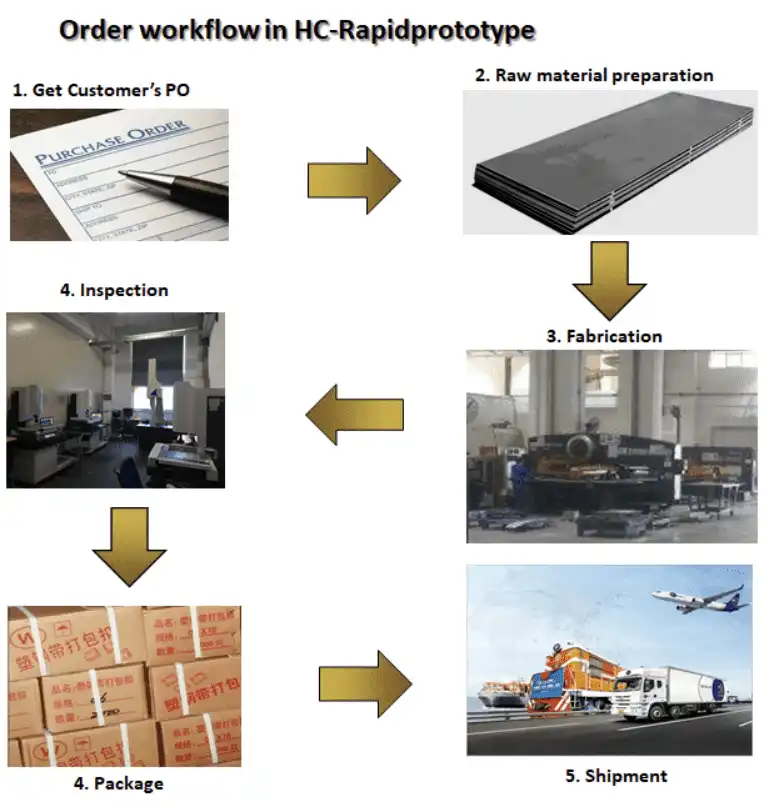

Order workflow

FAQs

Q: What is your quality process?

A: New drawings analysis - the internal production control conversion - drawing process flow chart - first manufacturing inspection - modified with numerical optimization - normal production - QC inspection record - surface treatment – FQCinspection report and record – packaging – logistics.

Q: What is the minimum order quantity for Custom Precision Sheet Metal Brackets?

A: We accommodate various order sizes, from small batches for prototyping to large-scale production runs. Contact us for specific quote details.

Q: Can you provide samples before full production?

A: Absolutely! We offer prototype samples to ensure your complete satisfaction before proceeding with bulk manufacturing.

Q: What is the typical lead time for custom orders?

A: Lead times vary based on complexity and quantity. Generally, we aim for 2-4 weeks for standard orders, but can expedite for urgent needs.

YOU MAY LIKE

_1744788508965.png)