Plastic Precision CNC Milling Parts

ShenZhenHuangCheng Technology Co.,Ltd. is a leading manufacturer and supplier of high-quality Plastic Precision CNC Milling Parts. Our advanced equipment, complete supporting facilities, and commitment to quality make us the go-to choice for industries requiring precision-engineered components.

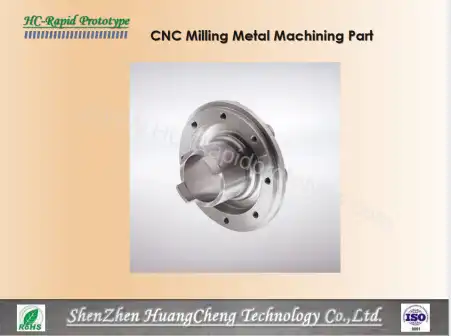

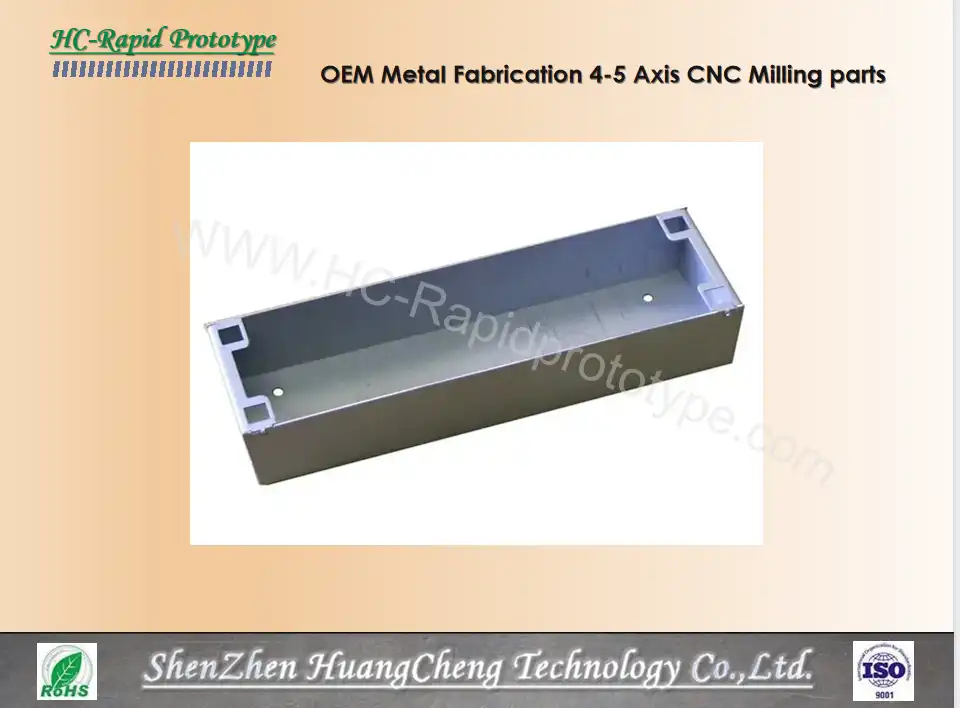

Our parts are the cornerstone of modern manufacturing, offering unparalleled accuracy and consistency for your production needs. These components are crafted using state-of-the-art CNC machining centers, ensuring tight tolerances and exceptional surface finishes.

Product Details

|

Product Name |

Plastic Precision CNC Milling Parts |

|

Sample Size |

3000x1200x600mm max. |

|

MOQ |

Not request , but the more the cheaper |

|

Processing |

CNC Milling/ Machining / Turning |

|

Material |

Delrin, POM, PVC,PU, PEEK etc. |

|

Surface Treatment |

Deburr |

|

Application |

Medical , Industrial Equipment and other industries |

|

Drawing |

PDF/DWG/STP/DXF/STEP/IGS/XT and so on |

Introduction

HC-RapidPrototype focus on plastic precision CNC milling parts for medical equipment from the latest CNC machines (Turning, Milling and grinding). With more than 10 years' experience in custom precision machining services, we are committed to provide high quality products with lower prices. We can produce CNC milling parts from various plastic material : such as : ABS, POM, PVC, PU, PEEK, PMMA, POM, PC, PA, PP, PBT, PPS, PE etc. And we can also do the secondary processing and sub-assembly work for you when CNC prototyping or production is completed. The samples processed by CNC have the advantages of large size, high strength, good toughness and low cost,it has become the mainstream of prototype production.

More Plastic Precision CNC Milling Parts for review

CNC plastic processing method

There are numerous sophisticated methods available for producing high-precision Plastic Precision CNC Milling Parts in today's manufacturing landscape. Modern industrial-grade plastics can be fabricated through techniques such as casting, injection molding, 3D printing, or machining. Casting allows for the production of large and intricate parts by pouring molten plastic into a mold, while injection molding is highly efficient for mass-producing consistent components with complex geometries and excellent surface finishes. 3D printing, especially with advanced polymers, offers the flexibility to create customized and complex designs layer by layer. However, when it comes to achieving extremely tight tolerances or producing a flawless, mirror-like surface finish on a wide variety of parts, machining stands out as the top choice. Approximately 80% of plastic parts undergo CNC milling, making it the most prevalent method for manufacturing parts without an axis of rotation. This process uses computer-controlled cutting tools to carve out the desired shape with precision. The remaining parts are typically crafted on lathes, which are ideal for producing rotationally symmetric components. To attain an exceptional surface finish, CNC machined parts often undergo additional post-processing steps like polishing or chemical treatment, ensuring they meet the highest quality standards.

Why Choose ShenZhenHuangCheng Technology Co.,Ltd.?

- Advanced manufacturing capabilities: Our state-of-the-art facilities and cutting-edge technologies enable us to produce high-quality products with precision and efficiency.

- Experienced technical team: Comprising seasoned engineers and skilled technicians, our team has a proven track record in solving complex manufacturing challenges.

- Rigorous quality control measures: From raw material inspection to final product testing, we implement strict quality checks at every production stage to ensure excellence.

- Flexible production volumes: Whether it's a small batch or a large-scale order, we can adjust our production lines to meet diverse customer requirements promptly.

- Competitive pricing: By optimizing our production processes and supply chain, we offer cost-effective solutions without compromising on product quality.

- On-time delivery: With efficient logistics management and a commitment to deadlines, we guarantee timely product delivery to meet your business needs.

- Excellent customer support: Our dedicated customer service team is available around the clock to address inquiries, resolve issues, and ensure a satisfying experience.

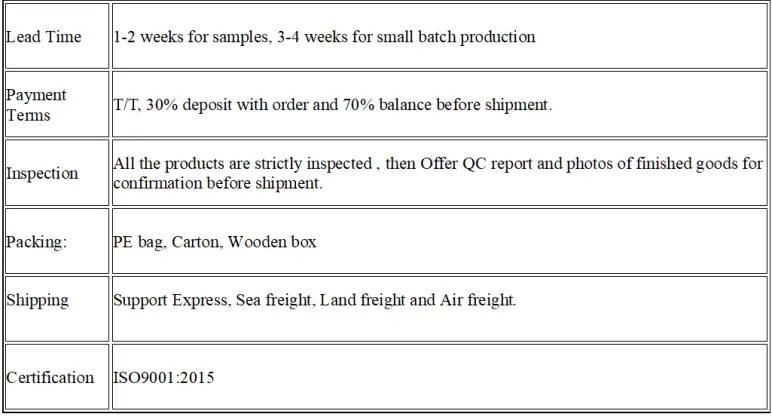

Delivery

FAQs

Q: How to control the quality?

A: 1.Compare and source the competitive 1st hand raw material

2.Inspection start from raw material sourcing then go along with manufacturing

3.Strict inspection and safe packaging before shipment

YOU MAY LIKE

_1744788508965.png)