Product Details

Material : Aluminum, stainless steel, Brass and other metals

Surface treatment: colorful Anodized, passivation

Machining method: CNC turning, CNC milling and CNC machining.

Application Industry: Car, Motorcycle, Bicycle, Scooter, Machinery, Electronics, Furniture

Tolerance: ISO 2768-m or customized

Delivery time: 5-10 working days.

Introduction

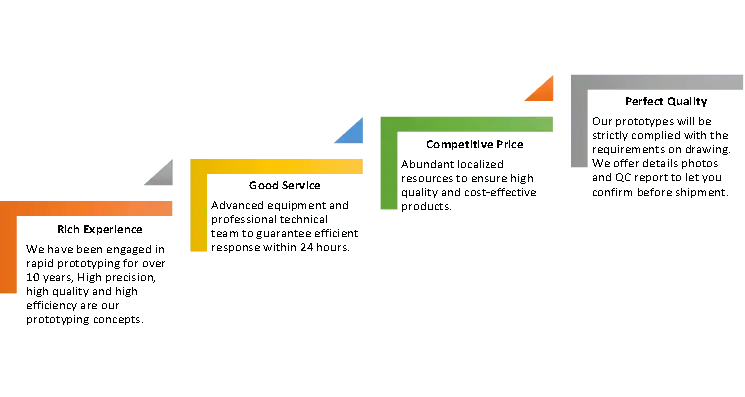

HC rapid prototype is a professional manufacturer specialized in non-standard high precision parts machining over 10 years. Our advantages are: Competitive Price, Good Service, Rich Experience, Perfect Quality.

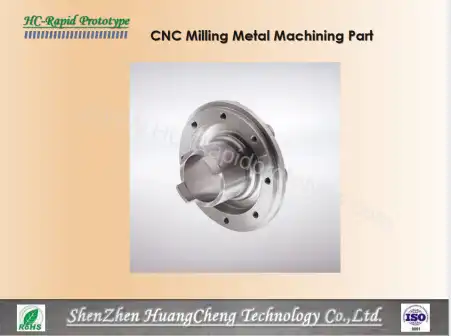

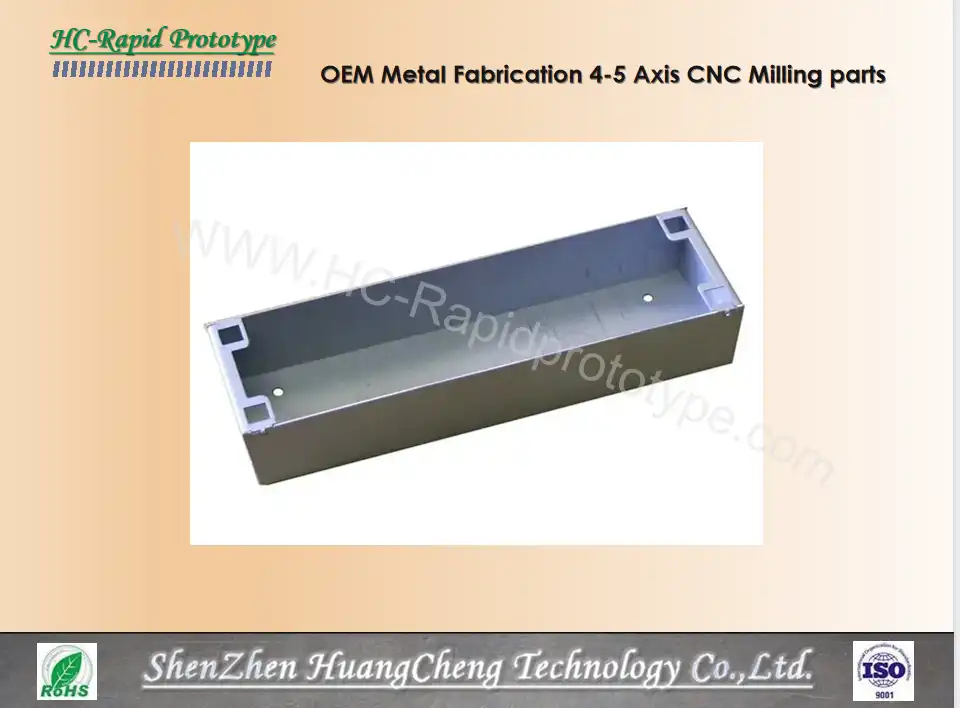

*Some Metal Fabrication CNC Milling Parts are shared as below

HC-Rapidprototype Advantage and Service:

- Advanced 4-5 axis CNC milling centers for complex part geometries: Our cutting-edge 4-5 axis CNC milling centers are equipped with the latest technology, enabling us to precisely machine intricate part geometries with high efficiency and accuracy that traditional methods can't match.

- Experienced engineering team for design optimization: Comprising seasoned professionals, our engineering team leverages their extensive expertise to analyze and optimize designs, ensuring they are not only manufacturable but also cost-effective and of the highest quality.

- Rapid prototyping and production capabilities: With state-of-the-art equipment and streamlined processes, we offer fast and reliable rapid prototyping services, and can smoothly transition to full-scale production to meet your timeline and volume needs.

- Comprehensive quality control measures: From raw material inspection to final product testing, our multi-layered quality control system involves strict checks at every stage, guaranteeing that all products meet or exceed industry standards.

- On-time delivery and responsive customer support: We prioritize punctuality and customer satisfaction. Our efficient production scheduling and dedicated customer support team ensure on-time delivery, while promptly addressing any inquiries or concerns you may have.

Product Characteristics:

- High dimensional accuracy and repeatability: Utilizing advanced metrology systems and precise machining equipment, we ensure that each part maintains exacting dimensional specifications. Rigorous calibration and automated processes guarantee consistent, repeatable results across every production cycle.

- Excellent surface finish: Employing optimized cutting parameters, specialized tooling, and post-processing techniques, we achieve a superior surface quality on all components. This not only enhances the aesthetic appeal but also improves functionality and reduces wear in mechanical applications.

- Capability to produce complex shapes and features: Our state-of-the-art 5-axis CNC machines, combined with expert programming and skilled operators, enable us to fabricate parts with intricate geometries, undercuts, and fine details that meet the most demanding design requirements.

- Consistent quality across large production runs: With an integrated quality management system, we monitor every stage of production. Automated inspection processes and real-time data analysis ensure that the same high standards are maintained throughout large-scale manufacturing, from the first part to the last.

Production Process:

- CAD/CAM programming: Our proficient team uses advanced software to convert designs into precise CAM programs. We optimize toolpaths, ensuring efficient machining and accuracy for seamless production.

- Material selection and preparation: Based on project requirements, we source top-quality materials. Then, we clean, cut, and treat them to make sure they are in perfect condition for CNC machining.

- CNC milling on 4-5 axis machines: Leveraging state-of-the-art 4-5 axis CNC machines, we execute complex milling operations. These machines enable us to produce intricate parts with high precision and efficiency.

- In-process quality checks: Throughout machining, our skilled inspectors conduct regular checks. Using precision measuring tools, they verify dimensions and surface finishes to maintain high-quality standards.

- Post-processing (if required): When necessary, we perform operations like deburring, polishing, or heat treatment. These steps enhance part functionality, appearance, and durability.

- Final inspection and packaging: Before shipping, we conduct a comprehensive final inspection. Then, we carefully package parts with protective materials to ensure safe delivery to customers.

Applications:

Our Metal Fabrication CNC Milling Parts find applications in:

- Aerospace components

- Automotive parts

- Medical device manufacturing

- Industrial machinery

- Defense industry equipment

- Telecommunication hardware

Delivery

1. Packing:

1) Method 1: shrink film, then bulk loading

2) Method 2: carton/ wooden case

3) Method 3: as customers’ requirement

2. Shipping: Support Express, Sea freight, Land freight and Air freight.

FAQs

Q1: Do you make customized products based on our design drawings?

A1: Yes. Nearly all our products are customized. We are a professional metal fabrication factory with an experienced engineering team to make custom products according to clients' drawings.

Q2: What is the MOQ?

A2: Usually we don't set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standards.

YOU MAY LIKE

_1744788508965.png)