Product Details:

|

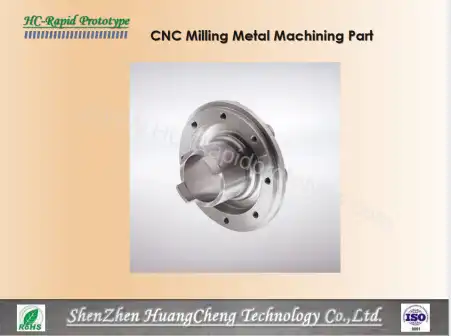

Name |

CNC Milling Aluminum Alloy Parts |

|

Size |

2 mm-1500mm / 0.08inch-60inch , or according to customer requirements |

|

MOQ |

No MOQ setting , the more the cheaper. |

|

Material |

A356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al Si Alloy, Al Cu Alloy, ZL201, Al Mg Alloy, ZL301,ZL302, Al Zn Alloy, ZL401Zn Alloy Or according to customer requirements |

|

Finishing |

Polishing, Plating, Anodized, Heat treatment, sandblasting, powder coating etc. |

|

Schedule |

Available in 7-15 days for different items |

|

Application |

Metal parts for vehicle, agriculture machine, construction machine, transportation equipment, Valve and Pump system. Engine bracket, truck chassis bracket, gear box, gear housing, gear cover, shaft, spline shaft, pulley, flange, connection pipe, pipe, hydraulic valve, valve housing, Fitting, flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft, transmission gear, sprocket, chains etc. |

|

Drawing |

2D (PDF, DWG, DXF) /3D ( IGS, STP, STEP, XT) etc. |

Introduction:

HC-Rapidprototype focus on CNC Milling Aluminium Alloy Parts services from the latest CNC machines (Turning, Milling and grinding). With more than 10 years' experience in custom precision machining services, we are committed to provide high quality products with competitive prices. We can provide CNC precision machining parts, CNC turning parts, CNC milling parts, surface grinding, CNC engraving etc.

Characteristics:

Our aluminum parts have many advantages:

- Good quality is our top priority across all aspects. In machining, we use advanced techniques for precision; our surface treatments enhance durability and appearance. Every product adheres strictly to specifications, and we ensure secure packing for safe transit.

- Proper suggestions are part of our commitment to your success. When you're unsure about materials or surface treatments, share your needs, and we'll offer expert advice. If machining reveals design flaws, we'll propose improvements, leaving the final decision in your hands.

- Lower cost in machining hardened metal is a key advantage we offer. Our innovative approach minimizes tool damage during the process of working with hardened metals, effectively reducing production costs without sacrificing quality.

- Good after - sales services ensure your peace of mind. Should the goods not meet expectations, we'll actively work to find solutions. We value your input and will consider your suggestions to resolve any issues promptly.

- Patience is at the core of our service. We understand your unique needs and challenges. Our team will patiently work with you, striving to provide the best service and tailored solutions for your projects.

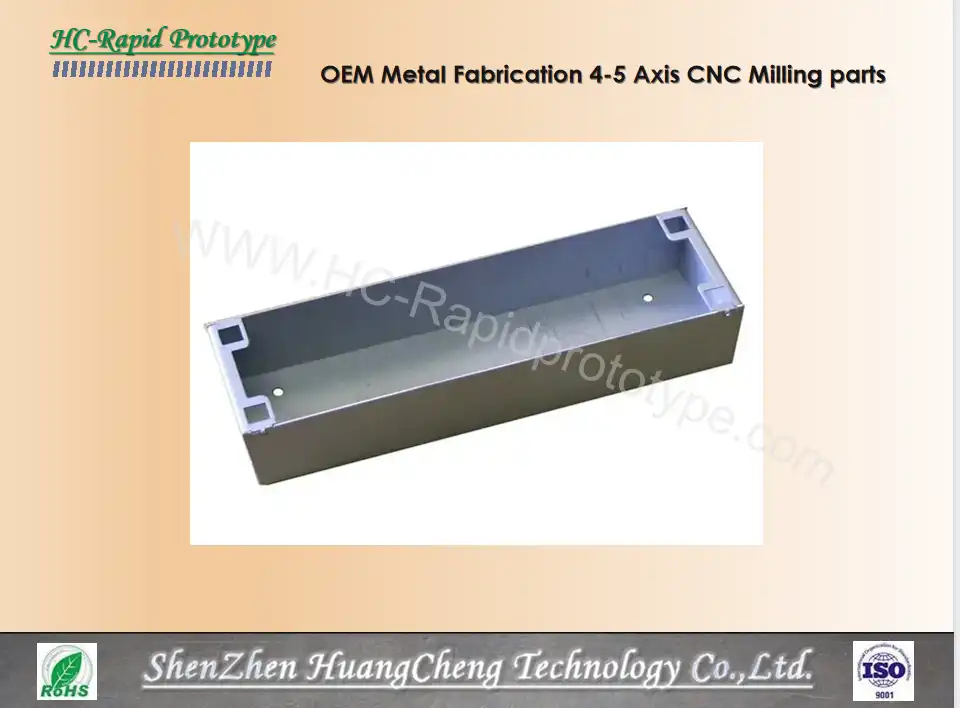

* More CNC Milling Aluminum Alloy Parts for your reference

Our Productive Process :

1. Design Review: Collaborate with your team to refine CAD models for manufacturability.

2. Material Selection:Source certified aluminium alloys for optimal performance.

3. CNC Machining: High-speed milling with multi-axis machines for accuracy.

4. Quality Inspection: CMM (Coordinate Measuring Machine) checks at every stage.

5. Post-Processing: Apply finishes like hard anodizing for corrosion resistance.

6. Packaging & Delivery: Secure shipping with documentation for global compliance.

Industries We Serve :

Our CNC Milling Aluminium Alloy Parts are trusted by:

-Automotive: Engine components, brackets, and custom fittings.

- Aerospace: Lightweight structural parts and prototypes.

- Electronics: Heat sinks, enclosures, and connector housings.

- Industrial Machinery: Precision gears, shafts, and robotic arms.

Why Partner With ShenZhenHuangCheng Technology?:

- 20+ Years of Experience:Technical know-how across industries.

- End-to-End Solutions:From prototyping to assembly-ready parts.

- Sustainability Focus: Recyclable materials and energy-efficient processes.

- Customer-Centric Approach: 24/7 support to resolve challenges quickly.

Remark:

|

Packaging |

Bubble Wrap/Pearl Wool +Carton+ Plywood Case / As per customized specifications |

|

Payment Terms |

T/T, 30% deposit with order and 70% balance before shipment. |

|

QC System |

100% inspection, then provide QC report and photos of finished goods for confirmation before shipment. |

|

Shipping Terms |

1) 0-100kg: express & air freight priority |

FAQs:

Q1: What is CNC Milling?

A1: CNC milling is one of the most common machining process to remove material. The rotary cutters are necessary when removing the material. The cutter is a cutting tool with sharp teeth rotating at high speeds. Material will be cutting away when feeding the workpiece into the rotating cutter. With times of operation, the desired shape can be made out. Generally, the milling machine have three axis: X, Y and Z. To produce the complex parts, 5-axis, 6-axis will be used.

Q: Do you provide material certifications?

A: Yes—every order includes mill test reports and compliance documentation.

Q: What’s your typical lead time for prototyping?

A: Prototypes ship in 7–10 days, with expedited options available.

Q: How do you ensure part accuracy?

A: Our CMM machines and in-house quality team verify dimensions at multiple stages.

YOU MAY LIKE

_1744788508965.png)