Product Details

|

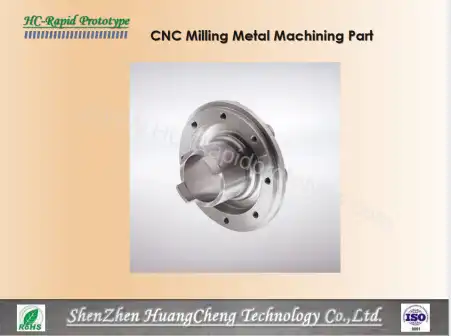

Product Name |

Good Quality CNC Milling Parts |

|

Product Size |

Refer to customer requirement |

|

MOQ |

1 piece for reference, low price depends on more quantity |

|

Processing Method |

CNC milling |

|

Raw Material |

Metal: Titanium, Aluminum, Stainless steel & Steel, Brass, copper etc. Plastic: POM, PEEK, ABS, Nylon, PVC, Acrylic etc. |

|

Surface Treatment |

Powder Coated, (Ordinary & Hard) Anodized, Electrolytic polishing &Plating, Bead Blasted, Heat treatment, Black oxide, Brushing, Laser engraving |

Introduction

HC rapid prototype has the natural geographical advantages, It is a professional manufacturer specialized in non-standard high precision parts machining over 10 years. Our benefits are:

*Competitive Price: Abundant localized resources to ensure high quality and cost-effective products.

*Good Service: Advanced equipment and professional technical team to guarantee efficient response within 24 hours.

*Rich Experience: We have been engaged in rapid prototyping for over 10 years, High precision, high quality and high efficiency are our prototyping concepts.

*Perfect Quality: Our prototypes will be strictly complied with the requirements on drawing. We offer details photos and QC report to let you confirm before shipment.

*Below is partial Good Quality CNC Milling Parts for reference

HC-Rapidprototype Advantage and Service:

- Rapid turnaround times: Our streamlined production processes, combined with advanced manufacturing technologies, enable us to complete projects quickly. We prioritize efficiency without sacrificing quality, ensuring you receive your products in the shortest possible time.

- Design for manufacturability (DFM) support: Our experienced engineering team offers in-depth DFM support, analyzing your designs to identify potential manufacturing issues. We provide practical recommendations to optimize designs, reducing costs and improving production efficiency.

- Competitive pricing for bulk orders: Leveraging our economies of scale and long-term supplier relationships, we offer highly competitive pricing for bulk orders. You can enjoy significant cost savings while still receiving top-quality products.

- Flexible production capacity: With a wide range of production equipment and a skilled workforce, we have the flexibility to handle projects of various sizes. Whether you need a small batch or large-scale production, we can adapt to your requirements.

- Comprehensive quality assurance: Our multi-layered quality assurance system encompasses every stage of production. From raw material inspection to final product testing, we conduct rigorous checks to ensure that all products meet the highest quality standards.

Product Characteristics:

- Precision-engineered for optimal performance: Each product is meticulously designed and crafted using advanced engineering techniques. Rigorous testing and fine - tuning ensure that it operates at peak efficiency, delivering unrivaled performance in its intended application.

- Excellent dimensional stability: Through precise manufacturing processes and careful material selection, our items maintain consistent dimensions. This stability withstands environmental changes and mechanical stress, ensuring reliable functionality over time.

- Superior surface finish: Employing specialized machining and finishing methods, we achieve a flawless surface texture. The smooth, blemish - free finish not only enhances aesthetics but also reduces friction and wear for better performance.

- High strength-to-weight ratio: Engineered with lightweight yet robust materials, our products offer an exceptional strength-to-weight balance. This feature enables weight reduction without sacrificing structural integrity, ideal for applications where efficiency matters.

- Corrosion-resistant options available: Understanding the need for durability in harsh environments, we offer corrosion-resistant variants. Treated with protective coatings or made from resistant alloys, these options combat rust and chemical damage effectively.

Production Process:

1. CAD/CAM programming

2. Material selection and preparation

3. CNC milling on advanced 5-axis machines

4. In-process quality checks

5. Post-machining treatments (if required)

6. Final inspection and packaging

Applications:

Our Good Quality CNC Milling Parts find use in a wide range of industries, including:

- Aerospace components

- Automotive engine parts

- Medical device housings

- Industrial machinery components

- High-performance racing parts

Comment

Packaging and shipment

1. Normally we pack goods according to customers’ requirement

2. Delivery: Support Express, Sea freight, Land freight and Air freight.

3. Our team will solve your problem. We will try our best to offer you good solution and best service.

FAQs

Q: How does HC control the quality?

A: 1)During processing, the operating machine worker inspect each sizes by themselves.

2)After finished the first whole part, will show to QA for full inspection.

3)Before shipment, the QA will inspect according to ISO sampling inspection standard. Then we will show you the QC report and detailed photos of finished goods for final confirmation.

4)when shipping the goods, we will attached the inspection report with the parts.

Q: What is your minimum order quantity for Good Quality CNC Milling Parts?

A: We accommodate orders of all sizes, from single prototypes to large production runs. Contact us for a custom quote.

Q: Can you handle complex geometries and tight tolerances?

A: Absolutely! Our advanced 5-axis CNC machines and skilled operators can tackle even the most challenging designs with precision.

Q: Do you offer material certifications?

A: Yes, we provide material certifications upon request to ensure full traceability and compliance with industry standards.

YOU MAY LIKE

_1744788508965.png)