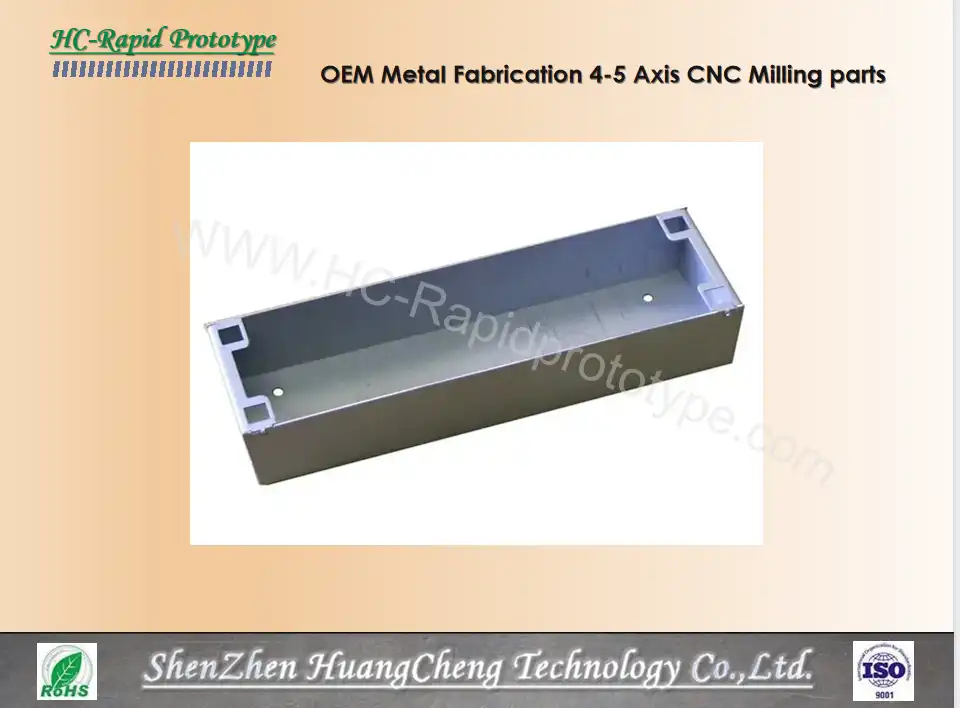

Product Details

|

Product Name |

OEM Metal Fabrication 4-5 Axis CNC Milling Parts |

|

Product dimension |

Refer to the shared drawing |

|

MOQ |

No requirement , normally unit price depending on quantity |

|

Processing Method |

CNC Milling |

|

Raw Material |

Steel, metal, stainless , aluminum alloy etc. |

|

Surface Treatment |

Anodized, Zinc-plated, nickel-plated, chrome-plated, silver-plated, gold-plated, passivation etc. |

|

Heat treatment |

Depends on customer requirement |

|

Application |

Automotive, Motorcycle, Machinery, Bicycles, Medical devices, Sporting equipment, Scientific Equipment, Electronics. |

Introduction

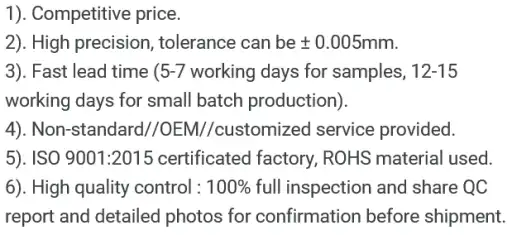

HC-Rapidprotype is specialized in manufacturing and trading OEM Metal Fabrication 4-5 Axis CNC Milling parts for more than 10 years. As one of the professional rapid prototyping suppliers in China, we can offer you customized service and quotation consulting service.

Product Characteristics

- High dimensional accuracy and repeatability are achieved through our advanced CNC machining technology and precise measuring systems. Rigorous calibration and monitoring ensure every part meets tight tolerances, and consistent results are replicated across multiple production cycles.

- Excellent surface finish is the result of our meticulous machining processes and state - of - the - art finishing techniques. Whether it's a mirror - smooth surface or a specific texture, we can deliver a high - quality finish that enhances both the functionality and appearance of the product.

- Capability to produce complex shapes and features sets us apart. Our multi - axis machining equipment, combined with skilled programming, enables us to create intricate geometries that traditional methods cannot achieve, opening up new possibilities for product design.

- Consistent quality across large production runs is guaranteed by our comprehensive quality control procedures. From raw material inspection to final product testing, every step is carefully monitored to ensure each item meets our stringent standards, providing reliability for mass production.

Production Process

- CAD/CAM programming utilizes advanced software to convert design concepts into precise machining instructions. Our expert programmers optimize toolpaths, ensuring efficient and accurate manufacturing while minimizing material waste.

- Material selection and preparation involve carefully choosing the right substances based on project requirements, considering factors like strength and durability. We then clean, cut, and treat materials to make them ready for machining.

- CNC milling on 4 - 5 axis machines enables us to handle complex geometries with ease. These multi - axis machines move along multiple directions simultaneously, creating intricate shapes and features with high precision and speed.

- In - process quality checks are essential to maintaining high standards. Our skilled technicians use various measurement tools to monitor part dimensions and surface finishes during machining, promptly addressing any deviations.

- Post - processing (if required) enhances the functionality and appearance of the parts. This may include deburring, polishing, heat treatment, or coating application, tailored to meet specific customer needs.

- Final inspection and packaging ensure that products meet all requirements before shipping. We conduct thorough checks using advanced equipment and package parts securely to prevent damage during transit.

Applications

Our OEM Metal Fabrication 4-5 Axis CNC Milling parts find applications in:

- Aerospace components demand the utmost precision and reliability. We produce high - performance parts, such as lightweight engine components and structural elements, engineered to withstand extreme conditions and ensure safe flight operations.

- Automotive parts are crafted to enhance vehicle performance and safety. Our offerings range from precision - made engine parts to durable suspension components, all designed to meet the rigorous standards of the automotive industry.

- Medical device manufacturing requires strict adherence to hygiene and quality. We fabricate components for various medical equipment, from surgical instruments to diagnostic devices, with a focus on biocompatibility and accuracy.

- Industrial machinery relies on robust and efficient parts. We manufacture heavy - duty components like gears, shafts, and frames, built to endure high loads and provide long - lasting performance in industrial settings.

- Defense industry equipment must be rugged and reliable. We create specialized parts that can withstand harsh environments, ensuring the effectiveness and durability of military hardware used in critical operations.

- Telecommunication hardware demands high - tech and reliable components. We produce parts for communication devices, such as antennas and circuit boards, designed to enable seamless data transmission and network connectivity.

Advantage of 4-5 axis CNC machine

Compared with 3-axis CNC machine, 4-5-axis CNC machine has the following advantages

1. Can be configured with various axes

2. More powerful functions

3. Faster keys for more convenient operation

4. Higher level of quality and precision

More 4-5 Axis CNC Milling Parts for your reference.

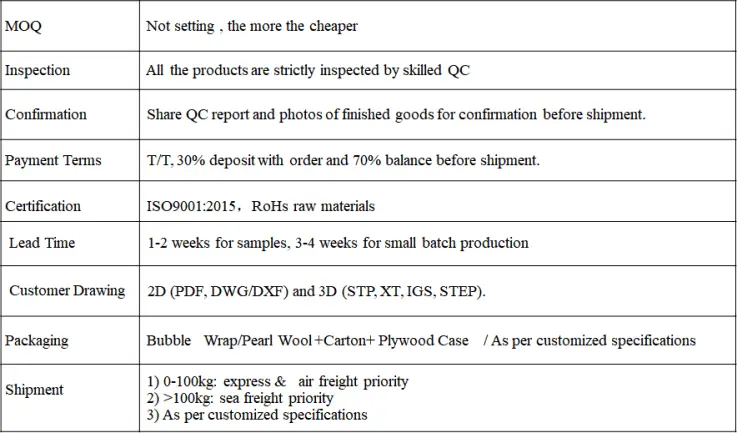

Delivering and shipping

FAQ

Q: What information should i let you know once i want to make a inquiry?

A: (1).The drawings ( DWG/PDF/STP/DXF/STEP/IGS/XT and so on)?

(2).The material for each drawing?

(3).The surface treatment requirement.

Q: How fast you can get quotation from HC ?

A: After get customer's detail enquiry( Clear drawings, material, QTY, surface treatment).

Normally, we will provide offer within 8 hours. For complex parts , will provide price within 24 hours.

Q: What is the minimum order quantity for the product?

A: We accommodate various order sizes, from single prototypes to large production runs. Contact us for specific requirements.

Q: Can you work with my proprietary designs?

A: Absolutely. We sign NDAs and ensure complete confidentiality for all customer designs.

YOU MAY LIKE

_1744788508965.png)