Product Details:

|

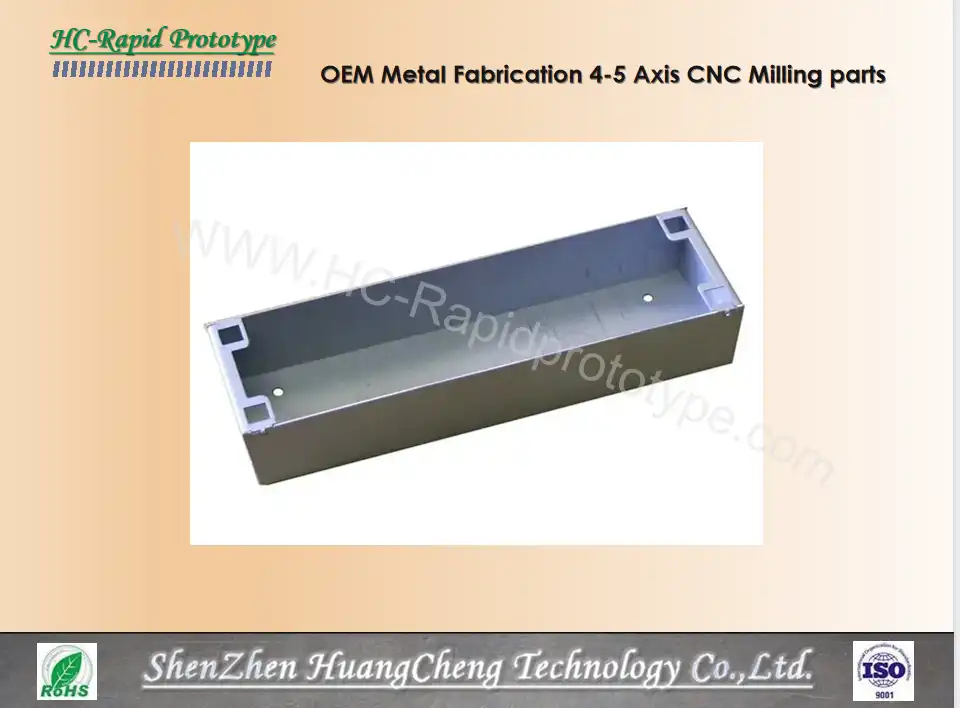

Product Name |

CNC Stainless Steel Milling Parts |

|

Dimensions |

Customized dimension or refer to the provided drawings |

|

MOQ |

1 piece |

|

Processing |

CNC Milling |

|

Raw Material |

Stainless Steel: 303, 304, 316 etc. |

|

Surface Treatment |

Painting, Electroplating, Coating, Passivation, electropolishing |

|

Heat treatment |

Partial or whole surface heat quenching |

|

Application |

Machinery manufacturing, aerospace, auto parts, Industrial Equipment |

|

Customer Drawing |

PDF, DWG, STP, DXF, STEP, IGS, XT and so on |

Introduction:

Many of HC's business is specialize in precision stainless steel parts which also includes CNC Stainless Steel Milling Parts, we providing the specialized expertise for your needs. And our processes are designed for the close tolerances, high cutting speeds and intense thermal loads demanded by stainless. below is our strong points:

1>. High-speed CNC machining equipment calibrated to maintain the cutting, machining and fine finishes demanded by stainless: Our high-speed CNC machining equipment is regularly calibrated to ensure precise cutting and machining of stainless steel. It can achieve the fine finishes required, delivering high-quality components with consistent accuracy.

2>. Highly skilled machinists with thousands of hours experience working with stainless steel: Our team consists of highly skilled machinists who have accumulated thousands of hours of experience in working with stainless steel. Their expertise ensures flawless production and the ability to handle complex projects.

3>. Competitive materials pricing due to long-term supply relationships: Thanks to our long - term supply relationships, we can offer competitive pricing on stainless steel materials. This allows us to provide cost-effective solutions without sacrificing material quality.

4>. Complete project management: We offer complete project management services, overseeing every aspect from initial design to final delivery. Our team coordinates resources effectively to ensure projects are completed on time and within budget.

5>. Appropriate handling and packaging to eliminate damage during shipping: We take great care in handling and packaging stainless steel products. Using suitable materials and techniques, we ensure that items are protected from damage during shipping and arrive in perfect condition.

*More CNC Stainless Steel Milling Parts for review

Our advantages and services :

1. ISO 9001: 2015 certified

2. Over 10 years OEM experiences

3. In house tooling design and fabrication

4. Advanced equipment ranged from 80T to 1650T

5. Highly skilled manufacturing process

6. Matched secondary machining equipment

7. Strict Quality Control System

8. On time delivery

Key Characteristics of Our Stainless Steel Milling Parts:

- Corrosion Resistance: Ideal for medical, marine, or chemical processing applications. Our products, crafted from specialized materials and treated with advanced processes, offer exceptional corrosion resistance. This makes them perfectly suited for use in demanding medical, marine, and chemical processing environments where exposure to harsh substances is common.

- High Strength-to-Weight Ratio**: Perfect for aerospace and automotive components. Engineered to provide an outstanding strength-to-weight ratio, our components reduce overall weight without sacrificing structural integrity. This feature is crucial for aerospace and automotive applications, enhancing fuel efficiency and performance.

- Customization: Collaborate with our engineers for design optimization (DFM support included). Our team of experienced engineers is ready to work closely with you. We offer comprehensive design optimization services, including DFM support, to ensure your designs are both functional and cost-effective to manufacture.

Why Partner With HC-Rapidprototype?

- Precision-Driven Production: Our high-precision CNC machining centers and 3D printing technologies guarantee consistency across bulk orders (100–10,000+ units). Leveraging cutting-edge equipment and advanced manufacturing processes, we maintain meticulous accuracy, ensuring each part meets exacting standards regardless of order size.

- End-to-End Quality Assurance: Every batch undergoes stringent inspections using CMM machines, ensuring compliance with your technical drawings and industry standards. From raw material checks to final product evaluations, our comprehensive quality control system, anchored by CMM technology, leaves no room for compromise on quality.

- Scalable & Flexible Solutions: Whether you need prototyping, low-volume runs, or mass production, we adapt to your schedule with JIT delivery options. Our versatile production capabilities and agile approach allow us to seamlessly scale operations, providing tailored solutions that align precisely with your project timelines.

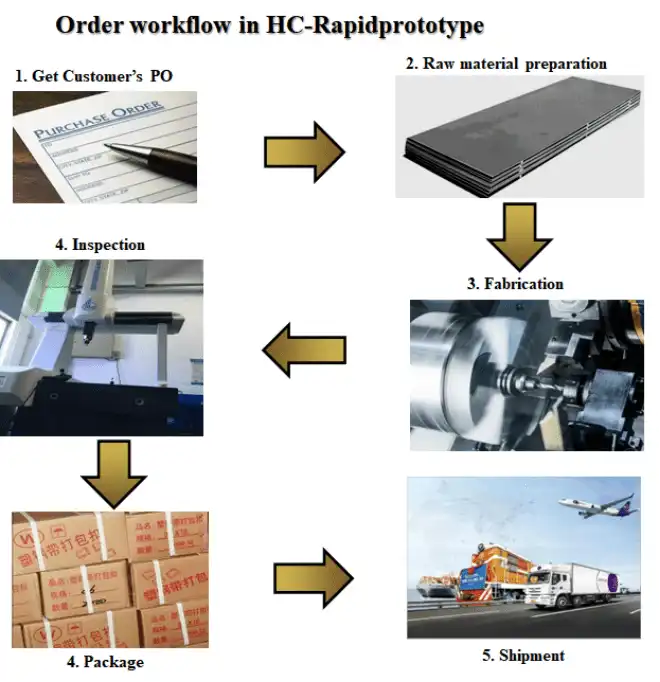

HC workflow and shipment:

FAQs:

Q: How Does Your Company Handle With Customer's Complaints?

A: The policy for us to handle with customer's complaint is CUSTOMER FIRST.

1) When get customer's complaints, we will inform all our related people, such as manager, engineer, quality people to

understand the whole situation and find out the reasons.

2) We will report to customer the reasons and best scheme.

3) Then to negotiate with customer and find the acceptable solution which both agreed.

YOU MAY LIKE

_1744788508965.png)