Product Details

|

Product Name |

Nylon-like vacuum casting parts |

|

Conductivity (σ) |

10-12 S/m |

|

Thermal conductivity |

0.25 W/(m·K) |

|

MOQ |

1 piece |

|

Raw Material |

UR-2180 |

|

Processing Method |

Plastic Vacuum casting |

Nylon-like properties

UR-2180 is a Japanese nylon-like plastic vacuum casting material. it has below characteristics:

Color: black, white, light yellow three colors;

Hardness: 87D;

Temperature resistance: 115 degrees;

Shrinkage: 0.25;

Features: Corrosion resistance, acid and alkali resistance, good strength, wear resistance (it is recommended to use transparent silicone as the mold).

Introduction

Nylon prototypes offer a diverse palette of colors, including classic black, pure white, and warm beige, providing designers and manufacturers with ample aesthetic choices to meet different project requirements. These prototypes are renowned for their exceptional properties, featuring high hardness that ensures structural integrity, remarkable aging resistance that prolongs their lifespan, robust toughness that enables them to withstand impacts, and excellent high-temperature resistance, allowing them to perform reliably in elevated - temperature environments. Additionally, nylon prototypes possess outstanding shock - absorbing and wear - resistant capabilities. Thanks to these superior characteristics, nylon prototypes have become a popular substitute for copper and alloys, widely utilized as wear - resistant components in various types of equipment. They are particularly well - suited for manufacturing a vast array of parts across multiple industries. In the realm of machinery, they are employed to create wear - resistant components and transmission structural parts. For household appliances, automotive manufacturing, and chemical machinery, nylon prototypes are used to fabricate essential parts. They can be found in numerous applications, such as turbines, gears, bearings, impellers, and cranks, as well as in more intricate components like instrument panels, drive shafts, valves, and blades. From high - pressure washers to simple screws and nuts, and from seals to shuttles, sleeves, and sleeve connectors, nylon prototypes play a crucial role in enhancing the performance, durability, and efficiency of countless products and equipment.

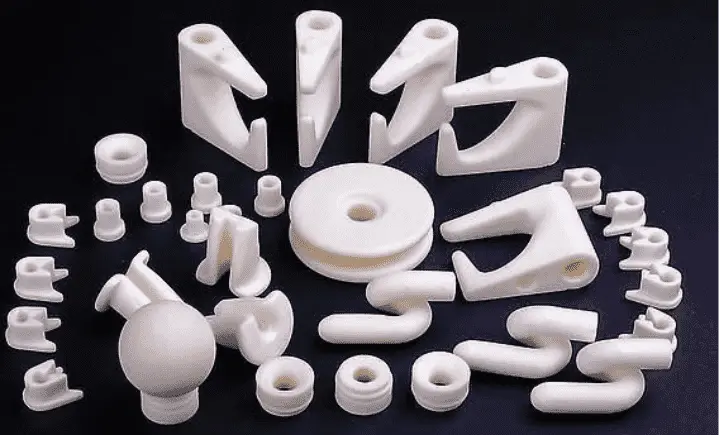

More Nylon-like vacuum casting parts for reference.

Advantages

Advantages of vacuum casting prototypes

1. The low cost of silicone mold stems from its simplified manufacturing process, eliminating the need for expensive tooling. This affordability makes it an attractive option, especially for small - scale projects and startups aiming to cut production expenses.

2. With fast delivery, silicone molds can be produced and shipped in a short time frame. This quick turnaround allows businesses to accelerate their product development cycles and respond promptly to market demands.

3. A wide selection of materials is available for silicone molds, offering versatility to meet diverse application requirements. Whether it’s for high - temperature resistance or specific chemical compatibility, there’s a material suitable for every need.

4. High precision and fine details are hallmarks of silicone molds. Advanced techniques ensure that even the most intricate designs are accurately replicated, resulting in parts that meet strict quality and dimensional standards.

5. An excellent surface finish is achieved with silicone molds, reducing the need for extensive post - processing. The smooth, flawless surface enhances the aesthetic appeal and functionality of the final products.

Why Choose ShenZhenHuangCheng?

- Our experienced professional team comprises skilled engineers and technicians with years of industry expertise. They leverage their in - depth knowledge to handle complex projects, delivering innovative and reliable solutions tailored to your needs.

- We utilize cutting - edge technology and equipment, constantly upgrading to the latest advancements. This enables us to achieve high - precision manufacturing, ensuring superior product quality and consistency in every production run.

- Our comprehensive quality control measures cover every stage of production, from raw material inspection to final product testing. Rigorous checks guarantee that all products meet or exceed the highest quality standards.

- We offer cost - effective solutions by optimizing production processes and leveraging economies of scale. This allows us to provide high - quality products at competitive prices without compromising on performance.

- With a flexible and customer - oriented approach, we adapt to your specific requirements. Whether it’s customizing products or adjusting production schedules, we prioritize meeting your needs and ensuring your satisfaction.

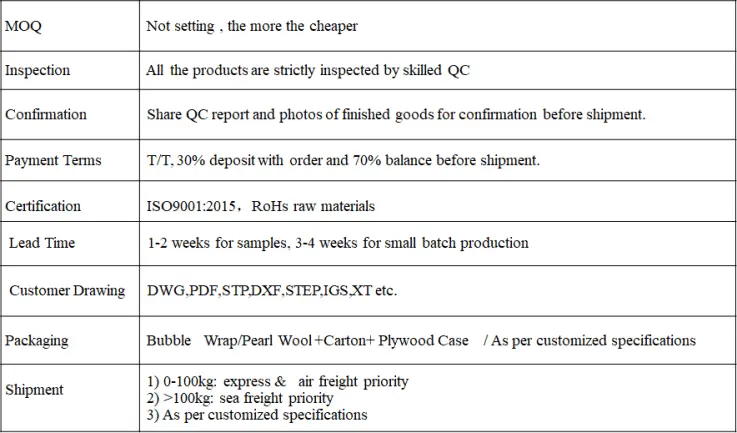

Delivery

FAQs

Q: What's the minimum order quantity for Nylon-like vacuum casting parts?

A: We offer flexible order quantities, starting from as low as 5 pieces.

Q: How long does it take to produce products?

A: Typical lead times range from 5-15 days, depending on part complexity and quantity.

Q: Can you produce parts with specific color requirements?

A: Yes, we offer a wide range of color options to meet your specific needs.

Q: How do the products compare to injection molded Nylon parts?

A: While they have similar properties, our vacuum cast parts offer faster turnaround times and lower tooling costs, making them ideal for prototyping and small production runs.

Q: Can you help with design optimization for vacuum casting?

A: Absolutely! Our experienced team can provide design suggestions to optimize your parts for the vacuum casting process.

YOU MAY LIKE

_1744788508965.png)