Product Details

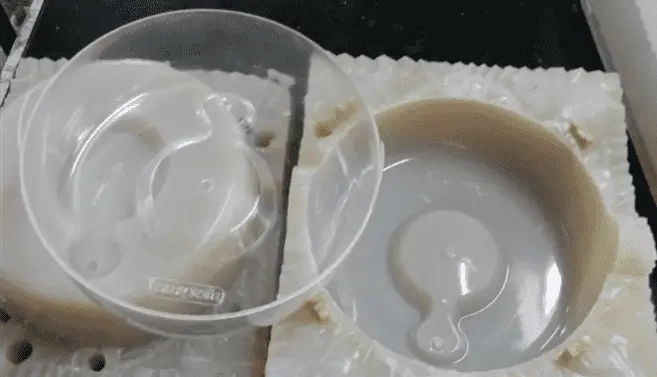

Category: Plastic vacuum casting

Product name: PP-like vacuum casting parts

Material: Hi-Cast 8550

Surface treatment: deburring, silk screen etc.

Water absorption is only 0.01%

Shrinkage rate (about 1%~2.5%)

APP-likelication:Commonly used in the manufacture of pots, barrels, furniture, films,

woven bags, bottle caps, car bumpers etc.

Introduction

The products offer significant advantages, particularly in terms of impact resistance and flexibility. Analyzing the characteristics of PP-like materials reveals a versatile substance with a range of beneficial properties. As a translucent material, PP-like is non-toxic and odorless, making it suitable for various applications, including those in consumer goods and medical devices. With a low density, it provides a lightweight option without sacrificing strength. In fact, its strength, stiffness, hardness, and heat resistance outperform those of low-pressure polyethylene, allowing it to be used effectively at around 100 ℃. It also exhibits excellent dielectric properties and high-frequency insulation, which remain unaffected by humidity. However, it has limitations; it becomes brittle at low temperatures, lacks wear resistance, and is prone to aging. Despite these drawbacks, its exceptional impact resistance and flexibility make it ideal for products with stringent impact requirements. For instance, it is commonly used in auto parts PP-like prototypes, ensuring durability during vehicle operation, and in half-packaged PP-like prototypes, providing both protection and flexibility.

PP-like Properties

Hi-Cast 8550 is a vacuum casting material developed for PE and PP prototype development with the following characteristics.

(1) Due to its low flexural modulus and high elongation, molded articles similar to PE and PP articles can be obtained.

(2) Has similar color to natural PE and PP products.

(3) It can be used to mold large items that can be used for a short time.

(4) The material is mainly used for prototypes manufactured by vacuum casting and Small-scale production.

HC-Rapidprototype Advantage and Service

When you choose HC-Rapidprototype for your PP-like vacuum casting parts, you're partnering with a company that values innovation and customer satisfaction. Our advantages include:

- Our rapid prototyping capabilities leverage advanced technologies like 3D printing and CNC machining. This enables us to quickly transform your design concepts into physical models, significantly reducing the time from idea to tangible prototype.

- With flexible production volumes, we can accommodate orders of any size. Whether you need a single prototype for testing or large - scale production runs, our adaptable processes ensure efficient and cost - effective manufacturing.

- We offer extensive customization options to meet your specific needs. From material selection and color choices to unique design features, our team works closely with you to create products that are tailored precisely to your requirements.

- Expert technical support is available throughout the process. Our experienced engineers and technicians are ready to assist at every stage, from design optimization to production troubleshooting, ensuring a smooth and successful project.

- Our competitive pricing is achieved through streamlined operations and efficient production methods. We maintain strict quality control standards, ensuring you receive high - quality products at prices that provide excellent value for your investment.

Hi-Cast 8550 basic properties

|

Item |

Value |

Remark |

|

|

Hardness |

Shore D |

76 |

Wallace hardness meter |

|

Tensile strength |

MPa |

34 |

JIS K-7113 |

|

Growth |

% |

72 |

|

|

Bending Strength |

MPa |

39 |

JIS K-7171 |

|

Bending modulus |

MPa |

960 |

|

|

Impact strength |

kJ/m2 |

10 |

JIS K-7110 Izod V Notch |

|

Shrinkage rate |

% |

0.3 |

In-house standards |

|

Load deflection temperature |

℃ |

70 |

JIS K-7207(1.80 MPa) |

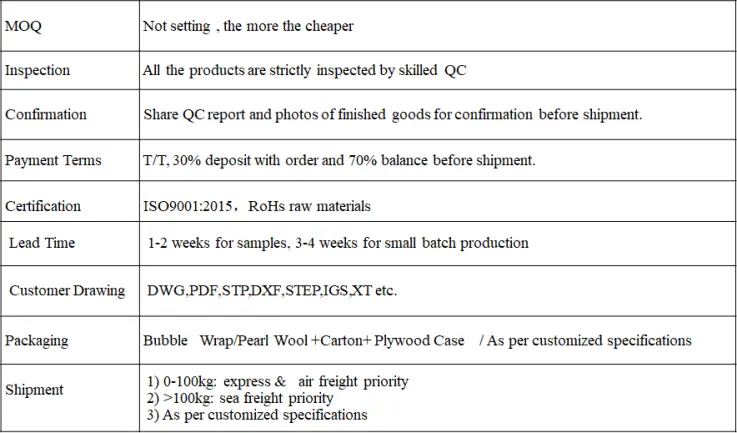

Delivery

FAQs

Q: What's the minimum order quantity for the products?

A: We offer flexible order quantities to suit your needs, from small batches to large-scale production runs.

Q: Can you provide samples before full production?

A: Absolutely! We encourage sample production to ensure the parts meet your exact specifications.

Q: What's the typical lead time for the products?

A: Lead times vary based on complexity and quantity, but we pride ourselves on quick turnarounds, often within 1-3 weeks.

Q: Do you offer design assistance for PP-like vacuum casting parts?

A: Yes, our team of engineers is available to provide design optimization suggestions to enhance performance and reduce costs.

YOU MAY LIKE

_1744788508965.png)