Product Details

|

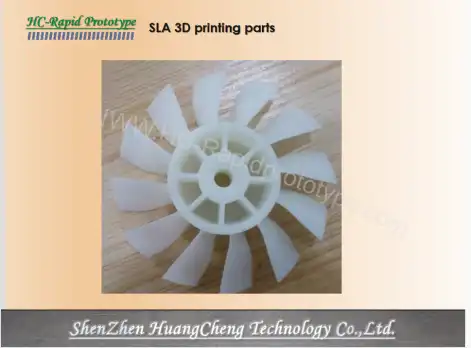

Product |

SLS 3D printing parts |

|

Size |

Customized Size |

|

Color |

Customized Color |

|

MOQ |

1 piece |

|

Processing Method |

Plastic 3D printing |

|

Raw Material |

ABS, Nylon, PP , TPU etc. |

|

Surface Treatment |

Polishing, painting, tinting etc. |

|

Application |

Medical equipment, craft toys, aerospace, auto parts, Industrial Equipment etc. |

Introduction

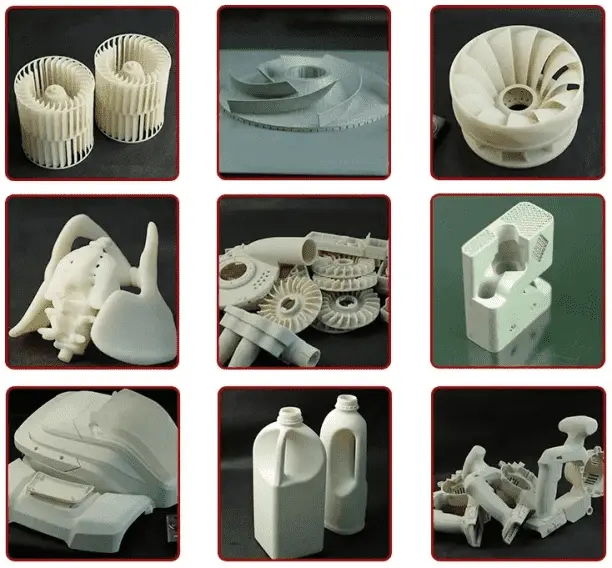

SLS 3D printing parts is the selective sintering of powder materials (mixed powders of plastic powder and binder) using a CO2 laser. It is a rapid prototyping method that integrates three-dimensional solids layer by layer through discrete points. Selective sintering of powder materials adopts carbon dioxide laser to selectively sinter powder materials (plastic powder, mixed powder of ceramic and binder, mixed powder of metal and binder etc.).

Before starting processing, The filled working chamber is heated and kept below the melting point of powder. During molding, the feeding cylinder rises and the dusting roller moves. Then spread a layer of powdered material on the working platform, after that, the laser beam sinters the powder in the solid part according to the cross-sectional profile under computer control, so that the powder is melted and a solid layer is formed.

After the sintering of contour layer is completed, the worktable is lowered to the height of cross-sectional layer, a layer of powder is spread on the next layer, then the next layer is sintered. This cycle will finally forms a 3D prototype part. After cooling for 5-10 hours, the parts can be removed from the powder container. The unsintered powder can support the sintered workpiece. When the sintering process is complete, get the final part.

SLS Advantages

1. Various materials can be used. In theory, any powder material that can form interatomic bonds after heating can be used as a molding material for SLS.

2. Accuracy, now the accuracy is normal to achieve a tolerance of plus or minus 0.1mm.

3. It does not need support, it does not need support structure, the suspended layer in the lamination process can be directly supported by the unsintered powder, which should be one of the biggest advantages of SLS.

4. The material utilization rate is high, and the sintered powder can be reused without wasting materials. thus, the price is relatively cheap.

SLS 3D Printing Tips

SLS is an incredibly versatile process that offers numerous possibilities for prototyping and production. Anything you can do to reduce the weight of a part without compromising performance will help keep costs down. Any thick sections you hollow out will need escape holes for excess material.

Since SLS manufactures parts from powdered material, it does have a rough surface finish and the resolution is not as high as some other processes. This is something to keep in mind when designing any fine detail or feature.

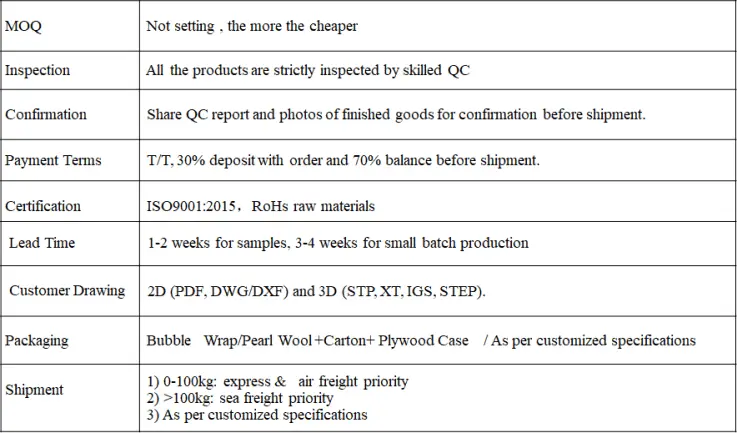

Delivery Info

FAQs

Q: What is the minimum order quantity for SLS 3D printing parts?

A: We accommodate various order sizes, from single prototypes to large production runs. Contact us for a custom quote.

Q: Can you provide material certifications for regulatory compliance?

A: Yes, we offer full material traceability and can provide necessary documentation for your industry requirements.

Q: What post-processing options are available for SLS 3D printed parts?

A: We offer various finishing options, including dyeing, polishing, and coating, to meet your specific needs.

Q: How long does it take to produce the products?

A: Turnaround time depends on order size and complexity. We pride ourselves on quick lead times and can provide estimates for your specific project.

Q: Do you offer design assistance for optimizing parts for SLS 3D printing?

A: Absolutely. Our engineering team can review your designs and suggest modifications to enhance printability and performance.

YOU MAY LIKE

_1744788508965.png)