Product Details

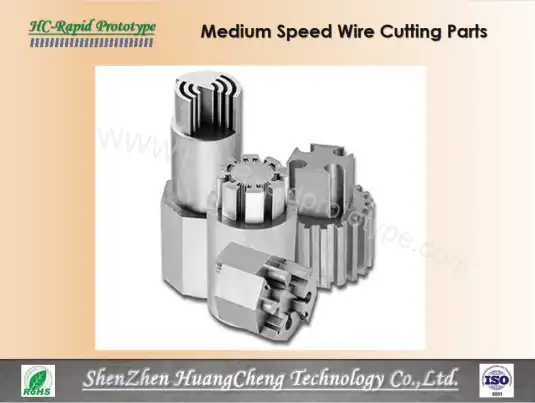

Some Low Speed Wire Cutting Parts for review

Introduction

The Low Speed Wire Cutting Parts utilizes a continuous wire feeding method for the wire electrode, where the wire electrode performs the machining while in motion. This unique operational approach offers a significant advantage. Even when the wire electrode experiences wear during the cutting process, it can be continuously replenished with new, unworn sections. This continuous replenishment ensures that the cutting edge remains sharp and consistent, thereby enhancing the machining accuracy of the parts being produced.

The surface finish of workpieces processed by the low speed wire cutting machine is highly impressive. Typically, the surface roughness can reach Ra=0.8μm and above, resulting in smooth and precise surfaces. Moreover, in terms of geometric accuracy, the roundness error, straight line error, and dimensional error of parts processed by the low speed wire cutting machine are far superior to those achieved by high speed wire cutting machines. Due to these outstanding precision capabilities, the low speed wire cutting process has become the go - to choice in the manufacturing of high - precision parts, finding extensive applications across various industries that demand strict dimensional and surface quality standards.

HC-Rapidprototype Advantage and Service

- State-of-the-art CNC machining centers and wire cutting machines are at the heart of our manufacturing capabilities. These advanced machines, equipped with the latest technology, ensure high precision and efficiency in every machining task, enabling us to produce complex parts with utmost accuracy.

- Rigorous quality control throughout the production process is our top priority. From the initial inspection of raw materials to the final testing of finished products, multiple checkpoints are in place to guarantee that every item meets or exceeds the highest quality standards.

- Quick turnaround times and on-time delivery set us apart in the industry. Our streamlined production processes and efficient scheduling allow us to complete projects promptly, ensuring that our clients receive their orders on schedule, every time.

- Expert technical support and after-sales service are integral to our commitment to customer satisfaction. Our team of skilled professionals is always available to provide assistance, answer questions, and address any concerns, ensuring a seamless experience long after the sale.

Comment

- Our advanced system is designed to automatically detect the thickness of the workpiece upon loading. It then intelligently adjusts the processing parameters in real - time, effectively preventing wire breakage. This optimization ensures that the machine operates at its peak, achieving the highest processing efficiency possible in any given situation.

- The double wire automatic exchange technology represents a significant leap forward in productivity. By seamlessly switching between two wires, it minimizes downtime and maximizes cutting time. In practice, this innovative feature can save a remarkable 30% to 50% of the overall cutting time, greatly enhancing production speed.

- With the fast automatic threading technology, the machine can complete the threading process in less than 15 seconds. This rapid operation reduces waiting times between machining tasks, enabling a more continuous workflow and increasing the overall throughput of the production process.

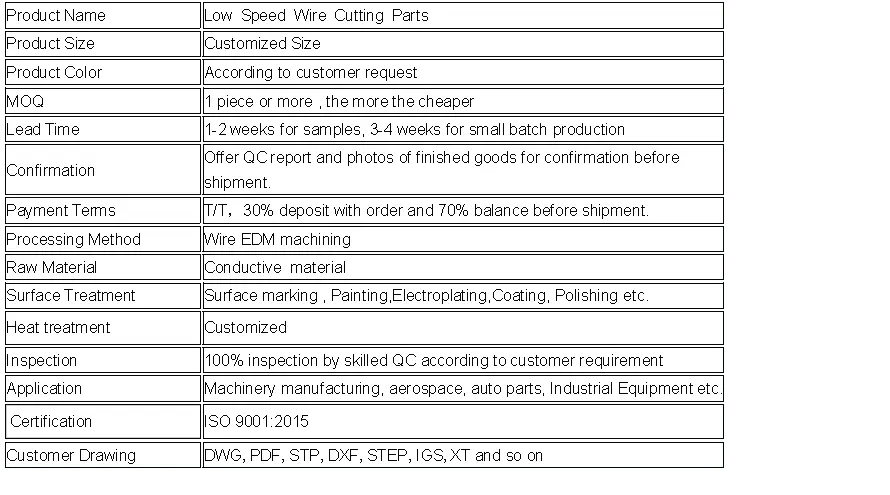

Product Characteristics

Our Low Speed Wire Cutting Parts are known for their:

- Superior durability ensures that our products can withstand the test of time and harsh environments. Built with high - quality materials and advanced manufacturing techniques, they resist physical damage and degradation, maintaining their integrity over extended usage.

- Excellent wear resistance is a key feature of our products. They are engineered to endure constant friction and abrasion, reducing the need for frequent replacements. This makes them ideal for applications where long - term contact and movement are involved.

- High precision and accuracy are hallmarks of our offerings. Utilizing state - of - the - art technology, we ensure that every product meets strict dimensional and functional standards, enabling seamless integration into complex systems.

- Consistent performance is guaranteed in all our products. Rigorous quality control measures at every production stage ensure that each item performs uniformly, providing reliable results regardless of the application or environment.

- Cost - effectiveness is achieved through a combination of efficient production processes and long - lasting quality. Our products offer great value for money, reducing overall costs by minimizing maintenance, replacement, and downtime expenses.

Packaging and shipment

|

Packaging |

Bubble Wrap/Pearl Wool +Carton+ Plywood Case / As per customized specifications |

|

Shipment

|

1) 0-100kg: express & air freight priority 2) >100kg: sea freight priority 3) As per customized specifications |

FAQ

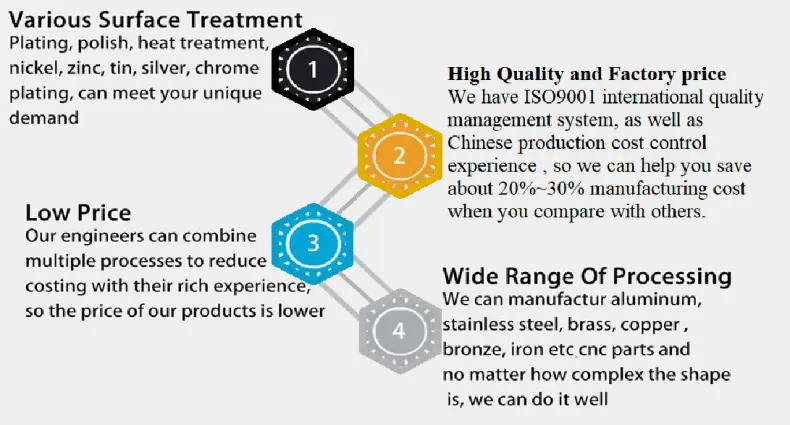

Q. What's the advantage of your factory compared to other manufacturing enterprises in China?

A: Comparing to other manufacturer, we can offer the following:

YOU MAY LIKE

_1744788508965.png)