Product Details

|

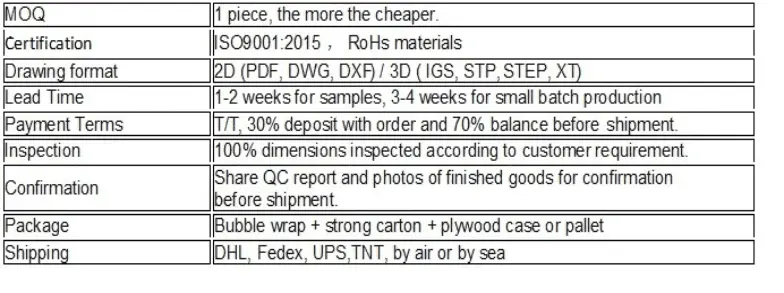

Product |

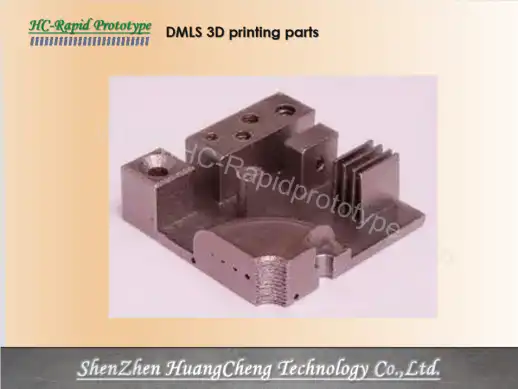

DMLS 3D printing parts |

|

Size |

Customized Dimension |

|

Material |

Copper, Maraging Steel, Stainless Steel, Cobalt Chromium Molybdenum Alloy, Aluminum Alloy, Titanium Alloy etc. |

|

Finishing |

Polishing, painting, tinting, plating etc. |

|

Application |

High-end precision manufacturing, aerospace, automotive, medical personalized parts manufacturing, small injection molds and inserts etc. |

Introduction

DMLS 3D printing parts stands as the pinnacle of 3D printing technology, revolutionizing the manufacturing landscape. This advanced process directly employs a high - energy laser to melt and deposit metal powder precisely. Simultaneously, it sinters and solidifies powder metal materials, enabling the automatic layer - by - layer stacking that culminates in the creation of dense, geometric solid parts. Unlike powder metallurgy, where voids may easily form during the molding process, DMLS benefits from the direct remelting of the dense metal, ensuring a superior quality build. Structural parts produced through DMLS can achieve a density of over 99%, closely approaching that of forged material blanks, which guarantees exceptional strength and durability.

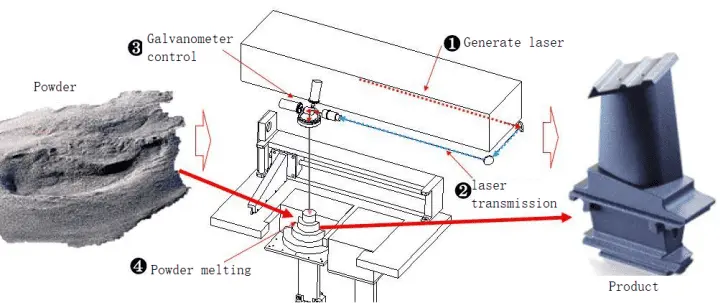

The main working principle of DMLS involves generating laser light via a CO2 laser. This laser light is then transmitted and meticulously controlled by a galvanometer, which accurately guides its path. As the laser strikes the metal powder, it melts the material, fusing each layer with the previous one. Through this iterative process, the final product is gradually built up layer by layer, bringing intricate designs and complex geometries to life with unparalleled precision.

Technology features

DMLS direct metal laser sintering technology features:

- The laser cladding layer and the matrix are metallurgically bonded, and the bonding strength is not lower than 95% of the original matrix material. Through laser - induced fusion, the cladding layer forms a strong metallurgical bond with the matrix. This ensures a bonding strength that's at least 95% of the original material, providing reliable structural integrity.

- The thermal influence on the substrate is small, and the deformation caused by it is also small. Laser cladding's concentrated heat source minimizes thermal diffusion in the substrate. As a result, the process induces minimal deformation, preserving the shape and dimensional accuracy of the base material.

- Wide range of materials. Laser cladding accommodates various materials, including metals like stainless steel, nickel - based alloys, and ceramics. This versatility enables customization to meet diverse application requirements.

- The cladding layer and its interface have dense structure, fine grains, no holes, no inclusion cracks and other defects. Precise control of the laser process leads to a cladding layer with a compact structure and fine - grained texture. It effectively avoids defects such as holes and cracks for high - quality results.

- It can repair the valuable parts and molds of large equipment that are partially worn or damaged to prolong the service life. For worn or damaged components of large equipment, laser cladding restores functionality. This extends the lifespan of valuable parts and molds, saving replacement costs.

- The controllability of the cladding process is good, and it is easy to realize automatic control. With adjustable parameters like laser power and scanning speed, the cladding process is highly controllable. It can be automated for consistent, efficient production.

- For damaged parts, high - quality and fast repair can be achieved, reducing downtime due to failures and reducing equipment maintenance costs. Laser cladding quickly and effectively repairs damaged parts, minimizing equipment downtime. This lowers maintenance costs by avoiding extended outages.

- The commonly used cladding layer hardness range is HRC30~60, the ultra - high hardness requirement can reach HRC65~75, and the thickness range of the cladding layer is 0.1~10.0mm. Offering a broad hardness spectrum from HRC30 - 60, with the option for HRC65 - 75 for special needs, and thicknesses from 0.1 to 10.0mm, it suits different application demands.

- Direct manufacturing of metal parts is possible. Leveraging laser cladding's layer - by - layer deposition, it can directly manufacture metal parts. This enables the production of complex geometries without traditional machining limitations.

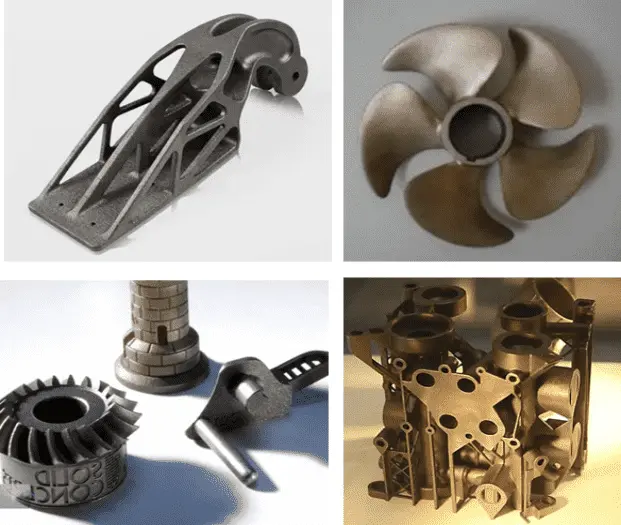

DMLS 3D printing parts for Reference

Advantages of DMLS

•Very suitable for functional parts and prototypes

• Ability to create complex geometries

• Can be produced in small batches

• Wide range of materials

Delivery Info

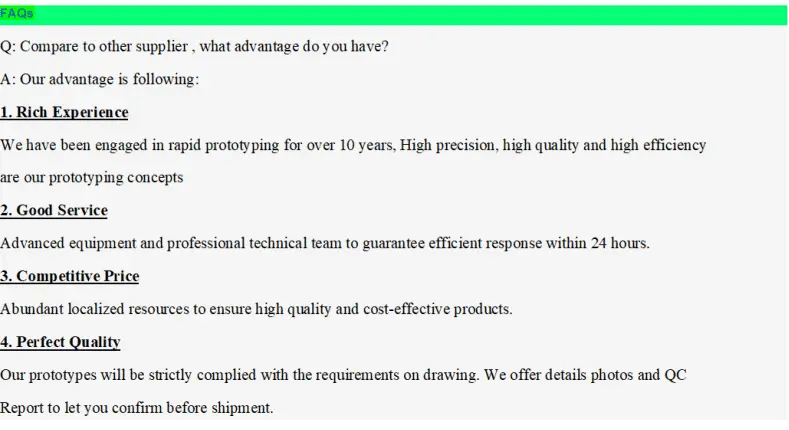

FAQ

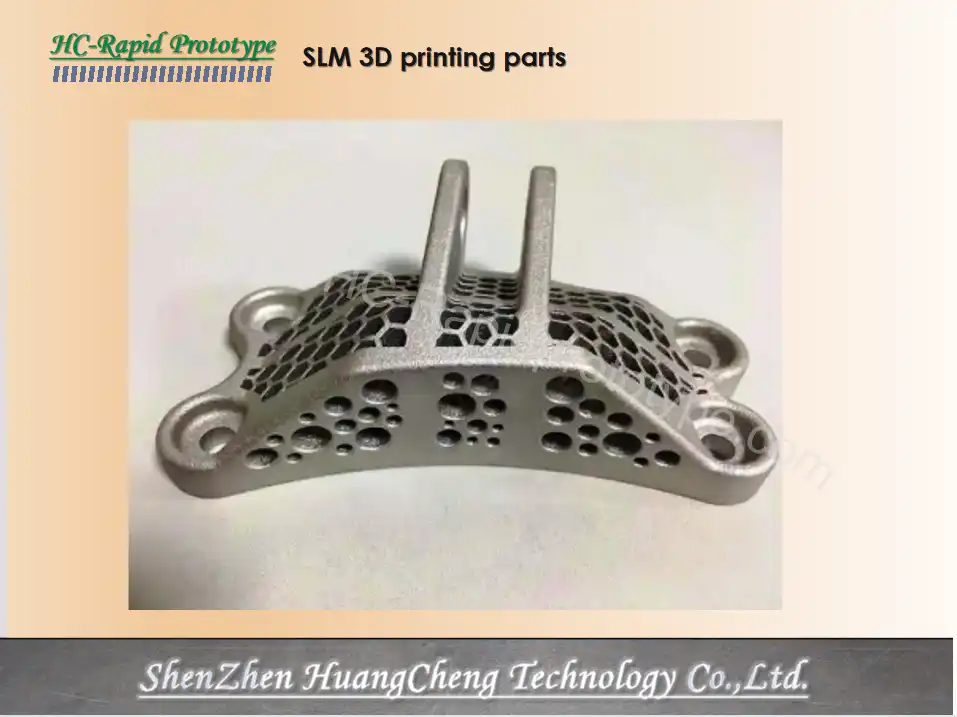

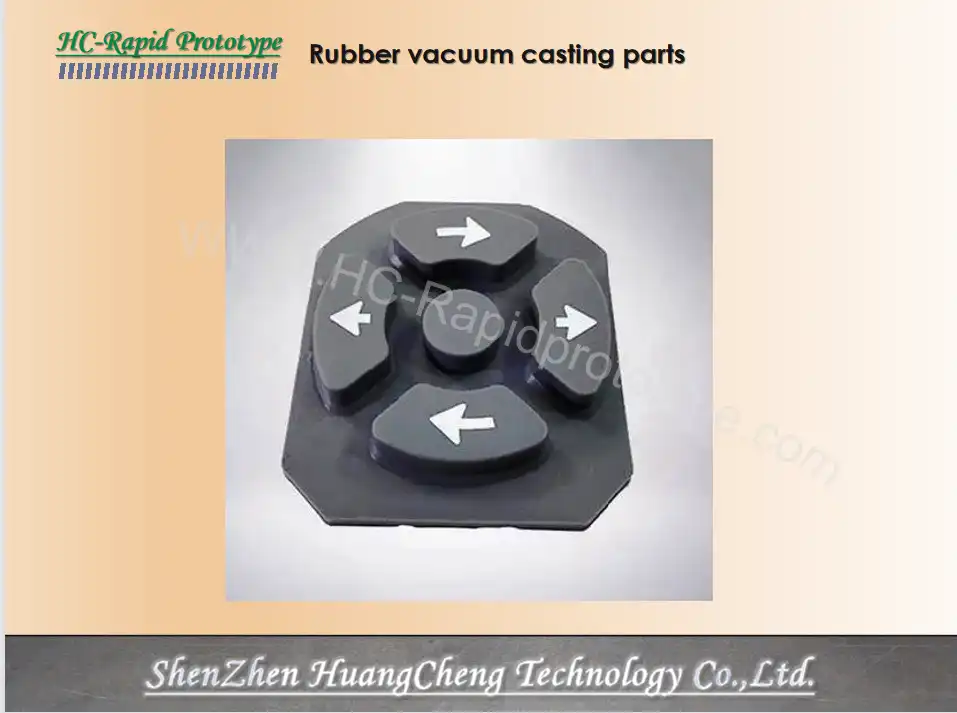

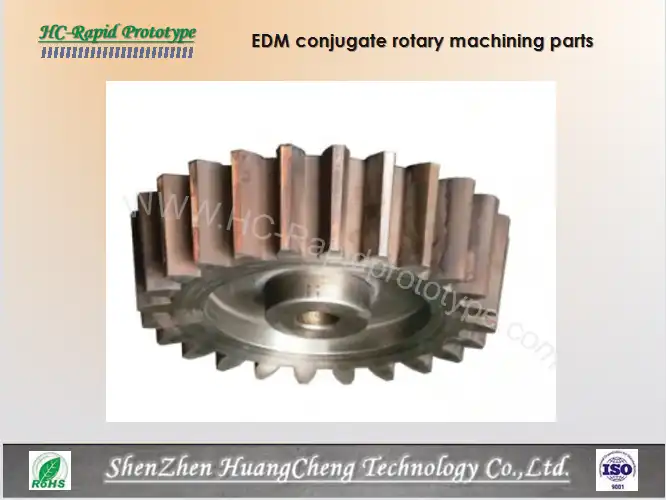

YOU MAY LIKE

_1744788508965.png)