Product Details

|

Product Name |

Professional CNC Turning Anodized Parts |

|

Product Size |

Customized Size |

|

Product Color |

Customized Color |

|

MOQ |

1 piece |

|

Processing Method |

CNC Turning |

|

Raw Material |

Aluminum or Aluminum alloy |

|

Surface Treatment |

Anodizing |

|

Application |

Machinery manufacturing, aerospace, auto parts, Industrial Equipment etc. |

|

Certification |

ISO9001:2015 |

|

Drawing |

2D & 3D drawings (PDF, DWG, DXF, IGS, STP, STEP, XT) |

Introduction

Professional CNC turning anodized process is an electrolytic oxidation process. It forms a layer of oxide film on the metal surface. This film has the following characteristics: strong texture, low proportion, scratch resistance, anti-pollution.

HC-Rapid prototype has evolved to provide the best solutions for our customer manufacturing needs for over 10 years, . Every part we produced in our CNC turning center is under the close supervision of CNC machinists team, who are dedicated to creating the best products within a timeframe and budget to fits your project needs.

These Professional CNC Turning Anodized Parts include fittings, shafts, rods, connector shell, with our latest and high performance equipment consisting of CNC turning centers and 4-axis turning machines.

CNC Turning Capabilities

Our Professional CNC Turning Anodized Part has a precision measurement of +/-0.005mm, producing parts with higher quality than ever before. Our ISO 9001 2015 certified machinery is capable of working with many different materials, ranging from more malleable materials such as aluminum and brass to more complex materials such as steel and can provide a variety of finishing processes.

Our CNC Turning Process

As soon as you get in contact with us, we will work together to find the best process to complete your project and create a plan catered around your budget and time frame. Depending on the part needed and its application, we can provide recommendations such as materials to get the high-quality and affordable CNC turned part possible. Our team of CNC turning experts will then begin the manufacturing process and delivered to you just in time.

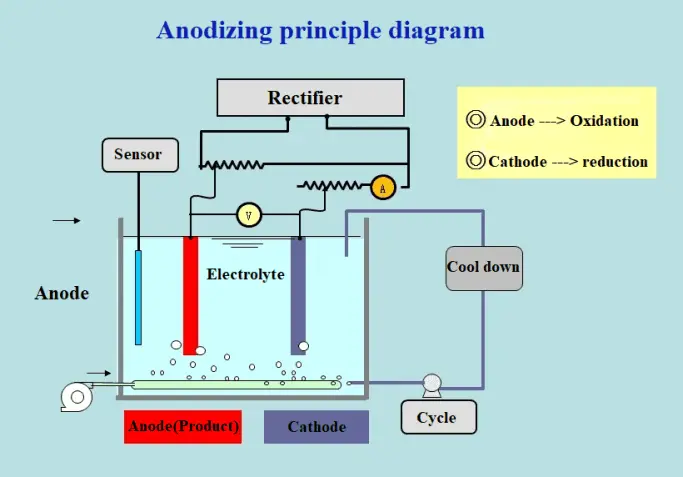

The principle and advantages of anodizing

Anodizing is an electrolytic process that deposits a chemically stable oxide layer on aluminum surfaces. The resulting oxide film is thicker and stronger than the native oxide coating of aluminum. It is hard, porous, and transparent, making it an integral part of metal surfaces ,so it will not peel off. Once deposited, the oxide film can be colored in a number of ways prior to sealing.

The thickness of its films is graded, with grade specifications ranging from 5 mm to 25 mm depending on the application. A thickness of 5 mm is typically used for decorative applications and 10 / 15 mm for interior applications. The exterior finish requires a film thickness of 25 mm. Anodizing is suitable for extruded, cast, rolled, drawn and forged aluminum products.

The advantages of anodizing as following:

- Strong texture: Our product boasts a super strong metal texture that exudes a high - end charm. It presents a beautiful and shining appearance, adding an elegant touch to any application, making it both visually appealing and luxurious.

- Low specific gravity: With a specific gravity merely one third of that of stainless steel, this material is incredibly lightweight. This feature not only simplifies handling but also opens up possibilities for a wide range of applications where weight is a crucial factor.

- Scratch resistance: The surface of our product has reached the sapphire - level hardness. This ensures that it remains free from unsightly scratches even after frequent use, maintaining its pristine look for an extended period.

- Strong anti - fouling: One of the remarkable advantages is its strong anti - fouling property. Even after being touched, it doesn't leave any fingerprints, keeping the surface clean and neat with minimal effort required for maintenance.

- Anti - static: Our product is anti - static, preventing it from attracting dust through vacuum - like effects. This characteristic makes it extremely easy to clean, saving both time and effort in daily upkeep.

- Good fire resistance: It is an environmentally friendly and non - toxic material that offers complete fireproofing. This makes it a safe choice for various settings, providing reliable protection against potential fire hazards.

- Anti - ultraviolet: Endowed with excellent weather resistance, our product effectively resists ultraviolet rays. This ensures that it maintains its integrity and appearance even when exposed to long - term sunlight, enhancing its durability outdoors.

- Non - fading: The color of our product is uniformly distributed and highly resistant to fading. No matter how long it is used or what environmental conditions it endures, the color remains vibrant and consistent.

- Strong hardness: As part of the special alloy series, our products exhibit exceptional hardness. This robust quality allows them to withstand significant pressure and mechanical stress, ensuring long - lasting performance.

FAQs

Q1: What is the standard of package?

A1: 1) Neutral packing (plastic bag + carton)

2) Custom packing (with logo or special package according to customer requirement).

Q2: How soon is your response?

A2: Within 24 hours.

Q3: What's the delivery time?

A3: 1) Sample: around 1-2weeks after receipt of deposit.

2) Bulk production: around 1-2 week after sample. (May vary depending on specific items and item quantities)

YOU MAY LIKE

_1744788508965.png)